71-80 / 2075 hits

| Main 3 products | Cutting machine palletizer jigu |

|---|---|

| Type of manufacturing | Jigs and tools Machine tools Industrial machinery |

| Recommended manufacturing category |

1:Product manufacturing - Production property - Energy-saving equipment/Automatic instrument manufacturing 2:Designing - Industrial equipment designing - Automatic machinery manufacturing 3:Designing - Industrial equipment designing - Carrier machine designing 4:Development and production of prototype/Small-scale production - Jig manufacturing - General jig manufacturing 5:Designing - Jig and tool designing - Mass production jig designing 6:Assembly/Inspection - Assembly - Industrial machinery assembly 7:Designing - Electrical planning - Electrical machinery and apparatus designing |

【高精度 精密プレス型 ダイカスト型 モールド モーターコア 】 【掲載機種 : YASDA YBM1224】 《大型超高精度機械加工》 ○ピッチ精度2000mmで3μm保証。 ○機械加工環境を通年20℃±0.5℃ 湿度50%以下に設定。 ○大型超精密プレス・鍛造金型のニーズに着目し、 ミクロンの切削加工技術を実現。

| Main 3 products | Micro-manufactured high-precision parts by micron-orders (Precision pressing, die-cast, molds, motor-core EV connectors, plugs) Measurement (Assurance of dimensions: ISO certificate organization) Sales of steel materials |

|---|---|

| Type of manufacturing | Jigs and tools Machine tools Transportation equipment |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - NC machining - 5-face/5-axis machining 2:Surface treatment - Heat treatment - Vacuum quenching 3:Development and production of prototype/Small-scale production - Machining - Simultaneous 5-axis machining 4:Designing - Data creation (3D scan) - Data creation (3D scan) 5:Development and production of prototype/Small-scale production - Prototype processing - Fused Deposition Molding (FDM) 6:Designing - Data creation (3D scan) - 3D printer 7:Surface treatment - Heat treatment - Sub-zero treatment |

NAOYA HIDA & Co.は、飛田直哉氏が手がける時計ブランドです。 熟練職人による手作業と最新鋭工作機械による加工を組み合わせた現代のヴィンテージ ウォッチ 協栄プリント技研株式会社では、独自の技術で、デザインを忠実に切削加工をした 時針、分針、秒針を提供しております。

| Main 3 products | Precision press dies [Design, manufacture and sales] Micro-manufactured parts [Manufacture and sales] |

|---|---|

| Type of manufacturing | Jigs and tools Telecommunication equipment Electronic parts |

| Recommended manufacturing category |

1:Die manufacturing - Press die - Blanking die 2:Development and production of prototype/Small-scale production - Machining - Handles microfabrication 3:Development and production of prototype/Small-scale production - Prototype processing - Simple mold, prototype mold 4:Die manufacturing - Cutting dies - Cutting blade cutting die 5:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 6:Die manufacturing - Rubber mold - Light electrical/earthing rubber 7:Die manufacturing - Press die - Fine blanking die |

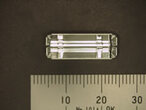

This is a connector part for PCs and tablets made of LCP. This is a plastic molded product with a size of 12.0 x 1.4 x 0.63 mm and tolerance range of 0.01 mm. We manufacture 60 poles (30 poles x 2 rows with 12 mm width) in molded product using a split die in consideration of liquidity. The tip has complicated shape, and the mold is designed and manufactured not only for accuracy but also for easy filling of resin. By adopting Yamaichi Seiko's original side gate, post-processing is not required, which leads to reduction of man-hours, cost reduction and stable quality (solving the problem of gate cut defects in the post-process). ◆ Product details Product name: connector parts for consumer use Industry: Electronic components (for PCs and tablets) Material: LCP (Liquid Crystal Polymer Super Engineering Plastic) Size: 12.0 x 1.4 x 0.63 mm Dimensional accuracy: 0.01mm ◆ PR Yamaichi Seiko Co., Ltd. provides integrated manufacturing of fine and precision plastic injection molded products by reliable mold processing technology to meet micron orders. We can handle design / manufacturing / maintenance of precision mold, mold parts and mechanical parts manufacturing, precision injection molded product manufacturing, molded products assembly to measurement contract, measuring jigs manufacturing, and flow analysis. We are equipped with a line that can stably produce and supply about 300 to 350 million injection molded products in Japan and overseas. We have about 300 injection molding machines (including the group) of 5t to 100t. We manufacture connectors, camera modules, industrial machinery and medical equipment parts, focusing on in-vehicle parts and electronic parts. We can handle fine and precision molded products from weight of 0.00006g up to the size of the hand palm. Production bases are in Japan (Ishikawa and Kyoto Prefecture), China (Dalian, Dongguan), the Philippines and Thailand (group companies) that covers Japan, East Asia, and Southeast Asia. All factories have acquired ISO 9001 and ISO 14001. IATF 16949 will be acquired in early 2023. Yamaichi Seiko Co., Ltd. 〒920-8203 5-177 Kuratsuki, Kanazawa City, Ishikawa Prefecture AUBEⅡ 3rd floor TEL: 076-237-1110 / FAX: 076-237-1120 http://www.yama-s.co.jp/top.html

| Main 3 products | Ultra-precision plastic injection molding mold Ultra-precision plastic molded product Plastic molded product assembly |

|---|---|

| Type of manufacturing | Industrial machinery Telecommunication equipment Electronic parts |

| Recommended manufacturing category |

1:Mass production - Plastic - Injection molding 2:Mass production - Plastic - Thin wall molding 3:Mass production - Plastic - LCP (liquid crystal polymer) 4:Mass production - Plastic - PPS (polyphenylene sulfide) 5:Mass production - Plastic - PBT (polybutylene terephthalate) 6:Mass production - Plastic - PI (polyimide) 7:Mass production - Plastic - Engineering plastic |

[SUS304 Emblem processing using die-sinker EDM] This is an example of SUS304 material processing using a die-sinker EDM. This is an example of emblem processing using a die-sinker EDM. Emblem processing is applied to SUS304 material. 【overview】 This is a sample product that we made when introducing a die-sinker EDM. In addition to aluminum, we can handle copper, iron, stainless steel, and difficult-to-cut materials. If you have any problems regarding the manufacturing of precision machinery parts, please contact us. 【size】 t12×40×100 [Processing equipment used] Mitsubishi Electric Die-sinker EDM EA12PSM X900 x Y650 x Z350

| Main 3 products | large machining Sheet metal and welding processing Industrial hard chrome plating/polishing |

|---|---|

| Type of manufacturing | Jigs and tools Machine tools Industrial machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Grinding processing - Cylindrical grinding 2:Development and production of prototype/Small-scale production - Grinding processing - Cylindrical mirror grinding 3:Development and production of prototype/Small-scale production - Grinding processing - Plane grinding 4:Development and production of prototype/Small-scale production - NC machining - 5-face/5-axis machining 5:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 6:Development and production of prototype/Small-scale production - Sheet-metal processing - Can manufacturing 7:Designing - Industrial equipment designing - Industrial machinery designing |

Realized cost reduction by changing the producing method. We have changed the method from sheet metal processing to press processing. Material: A1100 Size: w32.5 x L133.0 x H106.2 Thickness: t1.5 After pressing, it was anodized.

| Main 3 products | Loom machine parts Mold design/manufacturing and press processing Machine tool parts: die design/manufacturing and press processing Proposal pressing instead of machining |

|---|---|

| Type of manufacturing | Machine tools Industrial machinery Electronic parts |

| Recommended manufacturing category |

1:Mass production - Metal press - Thickness: 3.2 - 9.0 mm 2:Die manufacturing - Press die - Progressive die 3:Die manufacturing - Press die - Single press die 4:Mass production - Metal press - Progressive press (80 - 200 t) 5:Mass production - Metal press - Single press (80 - 200 t) 6:Mass production - Metal press - Iron 7:Mass production - Metal press - Stainless steel |

This is one of our technologies we are best at. Please feel free to contact us. <<Please contact us by email.>>

| Main 3 products | NC/MC processing Vacuum equipment parts processing Vacuum device valves/ high pressure valve processing |

|---|---|

| Type of manufacturing | Not selected Machine tools Industrial machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - TIG welding (argon welding) 2:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 3:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 4:Development and production of prototype/Small-scale production - Machining - Stainless steel 5:Development and production of prototype/Small-scale production - Machining - Aluminum alloy 6:Product manufacturing - Production property - Vacuum equipment manufacturing 7:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) |

| Main 3 products | press forming processing technology production of stamping dies by utilizing three-dimensional CAD/CAM and forming simulation sheet metal machining integrated manufacturing system |

|---|---|

| Type of manufacturing | Industrial machinery Transportation equipment |

| Recommended manufacturing category |

1:Mass production - Metal press - Drawing 2:Designing - Mold designing - Drawing metal press die designing 3:Mass production - Metal press - Bending 4:Mass production - Welding / welding - Spot welding 5:Mass production - Welding / welding - Robot welding 6:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 7:Development and production of prototype/Small-scale production - Blank cutting - CO2 laser machining |

| Main 3 products | Precision Parts Processing Inspection jigs Machining jigs |

|---|---|

| Type of manufacturing | Jigs and tools Measuring machinery Industrial machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 2:Development and production of prototype/Small-scale production - Grinding processing - Form grinding 3:Development and production of prototype/Small-scale production - Grinding processing - Plane grinding 4:Development and production of prototype/Small-scale production - Grinding processing - Profile grinding 5:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 6:Product manufacturing - Production property - Other industrial machinery manufacturing 7:Assembly/Inspection - Assembly - Precision equipment assembly |

We take digital camera reflectors from testing through to mass production. We process materials with high reflectivity. There are absolutely no scratches or oil.

| Main 3 products | Interior camera levers, lens mounts, camera reflectors Press stamping with plates made of special materials with a thickness of 0.03 Mold design, manufacturing, assembly, press stamping |

|---|---|

| Type of manufacturing | Lighting equipment Audio-video equipment Electronic parts |

| Recommended manufacturing category |

1:Parts manufacturing - Machinery part - Optical parts manufacturing 2:Mass production - Metal press - Progressive press (35 - 80 t) 3:Parts manufacturing - Electrical part - Connector manufacturing 4:Die manufacturing - Spring mold - Leaf spring die 5:Mass production - Metal press - Thickness: below 0.2 mm 6:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining 7:Die manufacturing - Press die - Drawing die |

71-80 / 2075 hits