81-90 / 2146 hits

This is one of our technologies we are best at. Please feel free to contact us. <<Please contact us by email.>>

| Main 3 products | NC/MC processing Vacuum equipment parts processing Vacuum device valves/ high pressure valve processing |

|---|---|

| Type of manufacturing | Not selected Machine tools Industrial machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - TIG welding (argon welding) 2:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 3:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 4:Development and production of prototype/Small-scale production - Machining - Stainless steel 5:Development and production of prototype/Small-scale production - Machining - Aluminum alloy 6:Product manufacturing - Production property - Vacuum equipment manufacturing 7:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) |

| Main 3 products | Precision Parts Processing Inspection jigs Machining jigs |

|---|---|

| Type of manufacturing | Jigs and tools Measuring machinery Industrial machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 2:Development and production of prototype/Small-scale production - Grinding processing - Form grinding 3:Development and production of prototype/Small-scale production - Grinding processing - Plane grinding 4:Development and production of prototype/Small-scale production - Grinding processing - Profile grinding 5:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 6:Product manufacturing - Production property - Other industrial machinery manufacturing 7:Assembly/Inspection - Assembly - Precision equipment assembly |

We take digital camera reflectors from testing through to mass production. We process materials with high reflectivity. There are absolutely no scratches or oil.

| Main 3 products | Interior camera levers, lens mounts, camera reflectors Press stamping with plates made of special materials with a thickness of 0.03 Mold design, manufacturing, assembly, press stamping |

|---|---|

| Type of manufacturing | Lighting equipment Audio-video equipment Electronic parts |

| Recommended manufacturing category |

1:Parts manufacturing - Machinery part - Optical parts manufacturing 2:Mass production - Metal press - Progressive press (35 - 80 t) 3:Parts manufacturing - Electrical part - Connector manufacturing 4:Die manufacturing - Spring mold - Leaf spring die 5:Mass production - Metal press - Thickness: below 0.2 mm 6:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining 7:Die manufacturing - Press die - Drawing die |

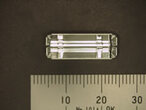

[Precision jig and tool parts manufacturing] This is a production example of precision jigs and tools. We have many achievements in machining with external dimensions of about 300 sq mm. We are also good at using both machining centers for machining and electric discharge machining for wire cutting, depending on the material, shape, delivery date and cost. We accept wide variety from single items, small lots to medium lots. Please feel free to contact us anytime. <External dimensions> 23mm x 25mm x 27mm <Materials we can handle> S45C, S50C, NAK55, NAK80, SKD11, PD613, SUS440C, SKH51, Various cemented carbide materials, etc.

| Main 3 products | Manufacture of various mold parts, parts for automatic machines and special-purpose machines, jigs and tools, and electrodes for die-sinking EDM Die-sinking EDM, wire cut EDM, small hole EDM, machining, NC milling, milling, forming grinding, surface grinding Iron, stainless steel, aluminum, copper, carbide, tungsten, titanium, inconel, conductive ceramic, etc. |

|---|---|

| Type of manufacturing | Audio-video equipment Telecommunication equipment Electronic parts |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Electrical discharge machine - Electric discharge machining |

Inner diameter polishing, lap, cemented carbide, dies, battery We specialize in processing cemented carbide and hardened steel parts, producing start from 1 piece. We perform integrated production of precision jigs, mold parts, and parts for automated machines in-house. By performing carbide brazing, shrinkage fitting, cold fitting etc. partially, the parts durability is improved and will reduce the frequency of maintenance that lead to productivity improvement. Depending on parts shape and purpose, we propose shape for carbide specification. Please feel free to contact us. SATSUMA PRECISION CO., LTD Person in charge: Deno info2@satsumanet.co.jp http://www.satsumanet.co.jp/ 2-9 Shinden Nakamachi, Daito City, Osaka Prefecture 574-0056 TEL: +81-72-871-6714 FAX: +81-72-871-6641

| Main 3 products | Precision parts processing Press mold design&manufacturing Precision machine parts |

|---|---|

| Type of manufacturing | Jigs and tools Machine tools Industrial machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Machining - High rigid material 2:Die manufacturing - Press die - Part processing 3:Development and production of prototype/Small-scale production - Grinding processing - Profile grinding 4:Development and production of prototype/Small-scale production - Grinding processing - Internal grinding 5:Die manufacturing - Press die - Plate machining 6:Surface treatment - Lap polishing - Lap polishing 7:Development and production of prototype/Small-scale production - NC machining - NC lathe machining |

From ultra-thin materials of 0.02mm to stainless steel, aluminum, and special metals, we offer precision press processing that caters to a wide range of materials, guaranteeing quality within short delivery times. Overview Our company is a specialized manufacturer engaged in precision press processing for a wide range of products, from automotive electrical parts to stationery parts. We can handle a diverse array of materials, from thin materials of 0.02mm to iron, stainless steel, aluminum, brass, and special metals. We pursue product precision and quality, offering custom-made solutions tailored to our customers' needs. Features Material Compatibility: Capable of flexibly handling a wide range of materials including iron, copper, nickel silver, phosphor bronze, stainless steel, plastic film, and mirror-finish aluminum. Precision Shaping: Capable of handling thin materials from 0.02mm to 2mm, including cutting, bending, and shallow drawing processes. We also accommodate the manufacture of products with complex shapes. High Proposal Capability: Offering optimal dies considering PM, production cut, life production number, and accuracy. We achieve cost reduction and quality improvement. Short Delivery Times: We maintain quality while flexibly meeting our customers' urgent needs with our short delivery system. Specifications Materials: Iron, copper, nickel silver, phosphor bronze, stainless steel, plastic film, mirror-finish aluminum, etc. Shapes: Processing of materials from 0.02mm to 2mm thick, cutting, bending, shallow drawing Proposals: Custom die proposals considering PM, production cut, life production number, accuracy Delivery: Short delivery times while maintaining quality Our precision press processing technology supports a wide range of materials, offering custom solutions to meet your manufacturing needs. Try our technology and experience to achieve high-quality products with short delivery times.

| Main 3 products | Automobile parts Manufacture of precision stamped parts Insert Molding |

|---|---|

| Type of manufacturing | Not selected |

| Recommended manufacturing category |

1:Parts manufacturing - Machinery part - Optical parts manufacturing 2:Mass production - Metal press - Progressive press (35 - 80 t) 3:Parts manufacturing - Electrical part - Connector manufacturing 4:Die manufacturing - Spring mold - Leaf spring die 5:Mass production - Metal press - Thickness: below 0.2 mm 6:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining 7:Die manufacturing - Press die - Drawing die |

Comprehensive Electrical Control Design Services to Enhance Manufacturing Productivity Overview F-1 Tools Co. specializes in electrical control design, offering a full range of services essential for the manufacturing industry, from circuit design tailored to customer needs, wiring, PLC programming, to servo motor settings. With consistent support, we achieve optimization of delivery time, cost, and performance. Features Support by experts: From electrical circuit design to trial operation, our experienced engineers provide high-quality services. Broad capabilities: We cover a wide range of needs, from setting to adjusting PLCs, servo motors, inverters, and other major manufacturer products. High-precision air micrometer settings: Our technical capability includes precise dimensional measurement with air micrometer settings, catering to detailed requirements. Specifications Our electrical control design services are customized to fit our clients' manufacturing processes. By utilizing the latest technology in PLC programming, servo motor and inverter settings, and precise air micrometer adjustments, we enhance productivity and efficiency. We also cater to all electrical control needs of the manufacturing industry, including network data management and mechanical device adjustments. F-1 Tools Co.'s electrical control design services offer comprehensive support from electrical circuit design, fabrication, delivery, to adjustment. Our skilled technicians perform high-quality electrical wiring work, and our engineers, armed with specialized knowledge, support the setting and adjustment of major manufacturer PLCs, servo motors, and inverters. We also handle air micrometer settings, network data management, and mechanical device adjustments, modifications, and overhauls, covering a wide range of electrical control needs. We support the trial operation of production equipment, ensuring stable production.

| Main 3 products | Processing machine assembly machine processing jig |

|---|---|

| Type of manufacturing | Jigs and tools Machine tools Industrial machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Grinding processing - Jig boring 2:Product manufacturing - Production property - Energy-saving equipment/Automatic instrument manufacturing 3:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 4:Development and production of prototype/Small-scale production - Grinding processing - Cylindrical grinding 5:Development and production of prototype/Small-scale production - Grinding processing - Plane grinding 6:Designing - Industrial equipment designing - Precision automatic machinery designing 7:Designing - Industrial equipment designing - Energy-saving machinery designing |

CPTD MALAYSIA SDN. BHD. is dedicated to providing companies with superior components for injection molds including cavities, cores, sliders, stamping dies, punches, dies, strippers and precision machine tools, along with CNC machining through state-of- the-art machinery and processes. CPTD opened its doors as a supplier of high precision components, injection molds and precision tooling for machinery components in April 2012. CPTD is 100% subsidiary of Chimera Co Ltd (HQ Japan) therefore the technology, quality, service and delivery time are indistinguishable from Chimera. For inquiries by email, please feel free to contact us at the address below. sales@cptdmy.com

| Main 3 products | CPTD MALAYSIA SDN.BHD. |

|---|---|

| Type of manufacturing | Not selected Jigs and tools |

| Recommended manufacturing category |

1:Designing - Mold designing - Injection molding die 2:Mass production - Mechanical processing - Fine particle material accepted 3:Development and production of prototype/Small-scale production - NC machining - Handles 3D processing 4:Mass production - Mechanical processing - Machining 5:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 6:Development and production of prototype/Small-scale production - Grinding processing - Form grinding 7:Development and production of prototype/Small-scale production - Grinding processing - Profile grinding |

Cutting (lathe, milling cutter, machining) Aluminum (A1070, A2017, A5052, A5056, A7075, Alqueen 300, Almigo), Chuck (mold) Machining method: Cutting (lathe, milling, machining) Material: Aluminum (A1070, A2017, A5052, A5056, A7075, Alqueen 300, Almigo) Part name: Chuck (mold) We specialize in small lot precision machining of jigs and tools and machined parts, including processing of machine parts for labor-saving equipment and precision measuring equipment. (We also manufacture precision parts by combining cutting and polishing). Based on our achievements and experiences, we also installed 5-axis machining and other machine's latest system to deliver products that satisfy our customers. Material procurement, heat treatment, and post-processing surface treatment (plating, etc.) are possible by cooperating with vendors with whom we do business. We can handle high flatness accuracy and surface roughness requirements from single item, including automobile parts, aircraft-related parts, and inspection jigs. Please feel free to contact us for ordering. Nomura Co.,Ltd 239-4 Unatecho, Kashihara City, Nara Prefecture 634-0834 TEL +81-744-21-2500 FAX +81-744-21-2501 http://www.nomura-industory.co.jp/

| Main 3 products | Labor-saving equipment Precision measuring equipment Machine parts processing |

|---|---|

| Type of manufacturing | Heavy electric machinery Jigs and tools Measuring machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 2:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 3:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 4:Development and production of prototype/Small-scale production - Grinding processing - NC cylindrical grinding 5:Development and production of prototype/Small-scale production - Grinding processing - NC plane grinding 6:Development and production of prototype/Small-scale production - NC machining - NC milling |

| Main 3 products | Aerospace Equipment |

|---|---|

| Type of manufacturing | Electronic parts Transportation equipment Construction material |

| Recommended manufacturing category |

81-90 / 2146 hits