- Telephone number: +66-2-136-6139

- FAX: +66-2-136-6140

- Website

- Basic Info

- Equipment

- Technology & Products

- History, Philosophy & Quality

- Map / HQ

Heat Sink for Electric Vehicles|Essential Role in EV Thermal Management

Category

The other

Brand name

Assist Work

Product info

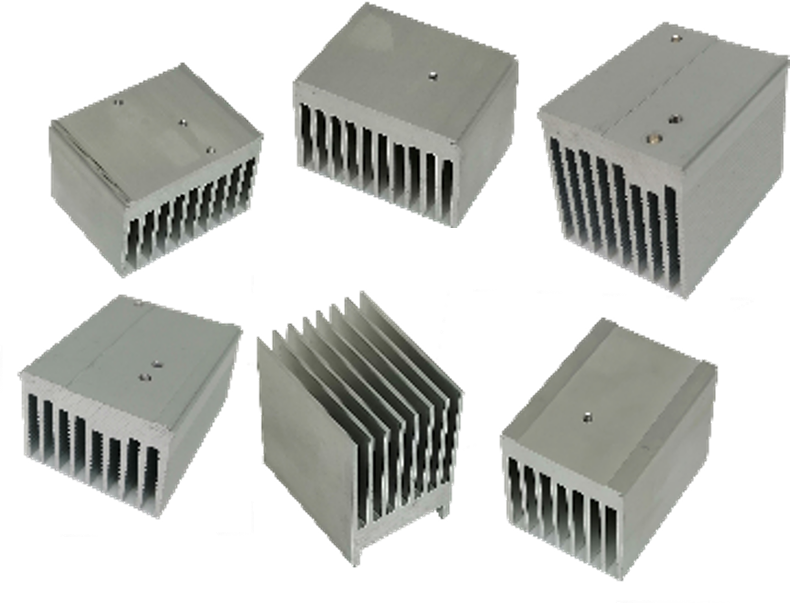

Heat sinks are crucial for managing heat in EV battery systems, inverters, and motors. This article explains how they protect EV components and improve efficiency, and why ASSIST’s heat sinks are trusted by top automakers.

■ What is a Heat Sink and How Does It Work in EVs?

A heat sink is a thermal management component that dissipates heat from electronic parts into air or coolant. In EVs, it prevents heat buildup in batteries, inverters, and motors, extending component life and improving performance.

■ Why Heat Sinks Are Critical in EV Applications

1. Battery System Cooling

- EV lithium-ion batteries generate intense heat during charge/discharge cycles.

- Without cooling, high temperatures accelerate degradation or cause thermal runaway.

- Heat sinks work with air/liquid systems to keep battery temps in check.

2. Inverter & Controller Protection

- Inverters and motor controllers heat up as they convert battery power to drive motors.

- Excessive heat reduces efficiency and causes long-term damage.

- Heat sinks help maintain stable operation and reliability.

3. Enhancing Motor Efficiency

- EV motors generate continuous heat under load.

- Poor cooling affects efficiency and may damage components.

- Heat sinks regulate temperature, easing the load on the cooling system.

4. Protecting In-Vehicle Electronics

- ADAS, displays, and control units are heat-sensitive.

- Heat sinks stabilise temperatures and prevent failures in EV electronics.

■ Emerging Heat Sink Technologies in the EV Industry

- Lightweight Materials: Aluminium and composites reduce EV weight.

- Advanced Fins & Conductive Materials: Fins increase surface area; materials like carbon nanotubes enhance dissipation.

- Liquid-Cooled Integration: New systems combine heat sinks with oil or insulating liquid cooling for advanced thermal control.

■ Why Choose Heat Sinks from ASSIST?

ASSIST is a trusted provider of heat sinks for the automotive industry with strengths in:

- Supplying top automakers like Honda, Suzuki, Mitsubishi, Mazda, and Nissan.

- Expertise in air conditioning system heat sinks and power transistor cooling.

- Exporting globally to Japan, the U.S., China, and India.

- Compliance with global manufacturing standards.

📥 Download our product catalog or contact our team for consultation.

#HeatSink #EVComponents #ElectricVehicle #BatteryCooling #InverterCooling #MotorCooling #ADAS #ThermalManagement #OEM

Company info

| Company name | ASSIST WORK (THAILAND) CO., LTD. | EMIDAS Member Number | 101168 |

|---|---|---|---|

| Country | Kingdom of Thailand | Street address |

Bangplee Samut Prakan Kingdom of Thailand |

| Telephone number | +66-2-136-6139 | Fax number | +66-2-136-6140 |

| Employees | 4,000,000 THB | Annual sales | |

| Employees | 60 | Person in charge | MAEDA : 085-669-1177 , Siriporn : 089-202-7035 |

| Type of manufacturing | Industrial machinery | ||

| Primary clients |

|

||