- Telephone number: +66-2-136-6139

- FAX: +66-2-136-6140

- Website

- Basic Info

- Equipment

- Technology & Products

- History, Philosophy & Quality

- Map / HQ

FC200 and FC250 Cast Iron Explained|Properties, Differences, and Industrial Applications

Category

The other

Brand name

Assist Work

Product info

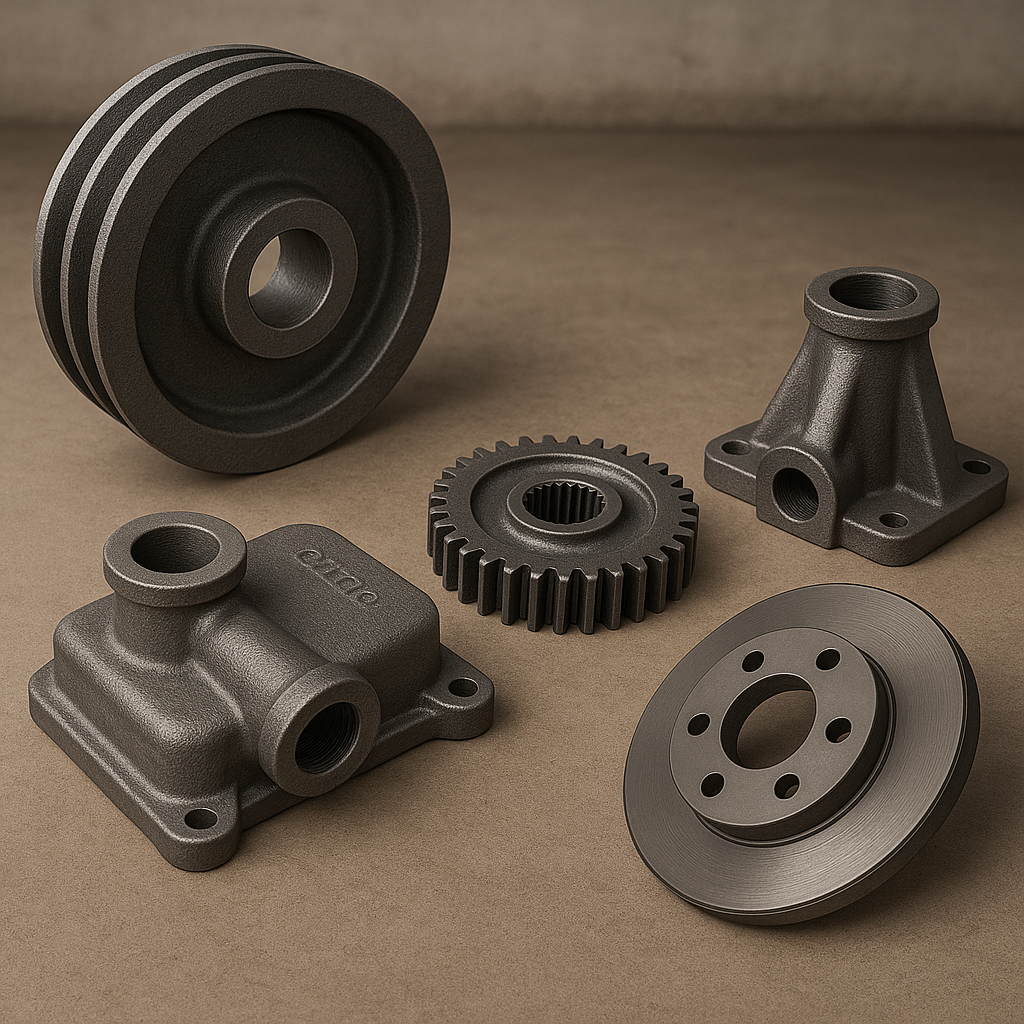

FC200 and FC250 are two essential cast iron grades widely used in industrial components. This article breaks down their differences, mechanical properties, and how to choose the right material for cost-effective and durable part production.

1. What Is Cast Iron?|Basic Overview

Cast iron is a metal alloy with a carbon content ranging from 2.0–4.0%, which is higher than steel. This composition gives it:

- High compressive strength

- Excellent vibration damping

- Good wear resistance

One of the most commonly used types is gray cast iron, where carbon exists as graphite flakes. This structure improves machinability and vibration absorption, making gray cast iron ideal for machine parts and industrial equipment.

2. FC200 vs FC250|Key Differences in Properties

Both FC200 and FC250 are standardized under JIS G5501 for gray cast iron. Their names reflect their minimum tensile strength (MPa).

● FC200 – For Easier Machining and General Use

- Minimum tensile strength: 200 MPa

- Average hardness: 180–230 HBW

- Ideal for non-load-bearing parts such as pump covers, casings, and light machine parts

- Cost-effective and easy to process

● FC250 – For High Strength and Load-Bearing Applications

- Minimum tensile strength: 250 MPa

- Average hardness: 200–260 HBW

- Suitable for gear housings, machine bases, and parts under continuous pressure or vibration

- Higher durability and dimensional stability

3. Common Industrial Applications

Both grades play important roles in manufacturing, particularly in machinery, automotive, and heavy equipment:

- Machine bases and frames → FC250 ensures high stability and vibration resistance

- Pump housings and covers → FC200 is economical and easily machined

- Lathe beds and drill platforms → FC250 offers excellent structural rigidity

- Gear housings and drive components → FC250 handles torque and stress effectively

- Brake drums → FC200 or FC250 selected based on performance requirements

4. How to Choose Between FC200 and FC250

● For high-stress or torque-heavy applications:

Choose FC250 – Its higher tensile strength is better suited for structural integrity under load.

● For cost efficiency and general machining:

Use FC200 – Easier to machine and ideal for parts not subjected to heavy stress.

● For fine detail or smooth surface finish:

Prefer FC200 – Better workability allows for precise cutting and finishing.

● For challenging environments (heat/vibration):

Select FC250 – Offers greater resistance to long-term environmental stress.

5. Why Choose Assist Work (Thailand) as Your Cast Iron Supplier?

Assist Work (Thailand) specializes in custom casting and machining of FC200 and FC250 components. With deep expertise in metallurgical characteristics and industrial standards, we deliver:

- Consistent quality

- End-to-end service (design, casting, machining)

- Customized support to reduce cost and improve performance

Our experienced engineering team is ready to assist with material selection, part design, and production efficiency.

#FC200 #FC250 #GrayCastIron #IndustrialMachining #MachineBase #GearHousing #CastIronParts #OEM #MetalCasting #ThailandIndustry

Company info

| Company name | ASSIST WORK (THAILAND) CO., LTD. | EMIDAS Member Number | 101168 |

|---|---|---|---|

| Country | Kingdom of Thailand | Street address |

Bangplee Samut Prakan Kingdom of Thailand |

| Telephone number | +66-2-136-6139 | Fax number | +66-2-136-6140 |

| Employees | 4,000,000 THB | Annual sales | |

| Employees | 60 | Person in charge | MAEDA : 085-669-1177 , Siriporn : 089-202-7035 |

| Type of manufacturing | Industrial machinery | ||

| Primary clients |

|

||