- Telephone number: +66-2-136-6139

- FAX: +66-2-136-6140

- Website

- Basic Info

- Equipment

- Technology & Products

- History, Philosophy & Quality

- Map / HQ

A6063 and Aluminum Extrusion|The Process Behind High-Quality Industrial Components

Category

The other

Brand name

Assist Work

Product info

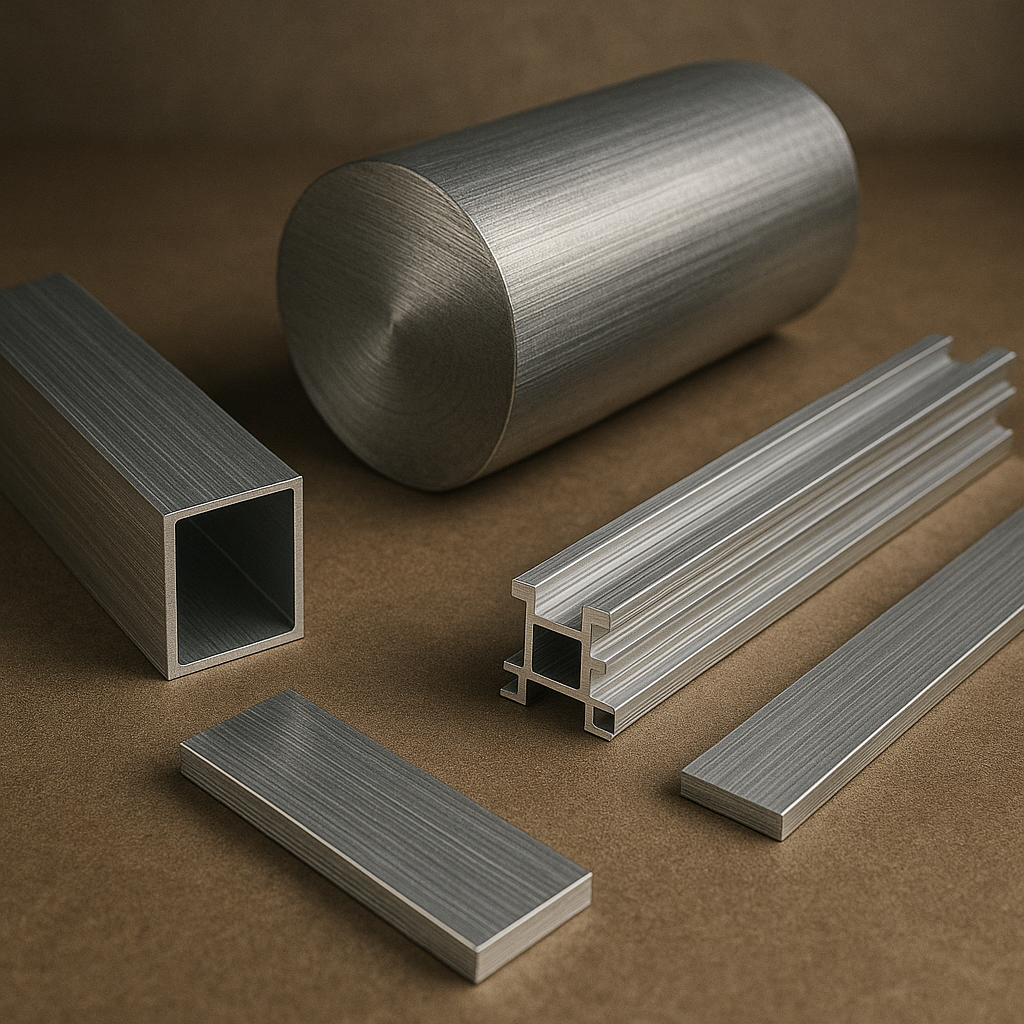

A6063 is a high-performance aluminium alloy known for its excellent extrudability and surface finish. This article explains why A6063 is the preferred choice for aluminium extrusion, how the process works, and where it’s used in industry.

1. What Is A6063?|A Trusted Alloy for Extrusion and Engineering

A6063 is a member of the 6000-series aluminium alloys, combining aluminium, magnesium, and silicon to create a well-balanced material that is:

- Lightweight

- Structurally strong

- Highly extrudable

- Easy to anodise or coat

It’s commonly used in construction, architecture, solar energy systems, and industrial machinery where precision, appearance, and corrosion resistance are essential.

2. Why A6063 Is Ideal for Extrusion Applications

● Excellent Formability

Its optimised Mg-Si composition allows for smooth, consistent flow through extrusion dies.

● Smooth Surface Finish

A6063 produces clean, uniform surfaces ideal for visible parts like window frames or structural trims.

● Anodising and Coating Compatibility

It accepts anodising, powder coating, or other surface finishes easily, making it corrosion-resistant and visually appealing.

● Lightweight but Strong

A6063 is strong enough for most light to medium-duty structural applications, both indoor and outdoor.

3. The A6063 Aluminium Extrusion Process

Aluminium extrusion is a multi-step, precision-controlled process. Here's how it works with A6063:

3.1. Billet Preparation

Aluminium billets are cut and preheated to extrusion temperature.

3.2. Extrusion Through Die

The soft metal is pushed through a custom die using hydraulic pressure, forming the desired cross-section.

3.3. Cooling

Extruded parts are rapidly cooled—either by air or water mist—to maintain shape.

3.4. Stretching

Parts are stretched to correct any distortion and relieve internal stress.

3.5. Cutting and Ageing (Heat Treatment)

The profiles are cut to the required lengths and aged to reach T5 or T6 temper, enhancing strength and durability.

Every step is carefully controlled to ensure precision, dimensional accuracy, and consistent quality.

4. Applications of A6063 in the Industrial Sector

A6063 aluminium is a go-to material across industries where visual quality and moderate strength are needed. Typical uses include:

- Window and Door Frames – Lightweight and sleek for easy installation

- Solar Panel Structures – Weather-resistant and ideal for outdoor exposure

- Machine Frameworks – Used in conveyor systems and factory automation lines

- Architectural Elements – Railings, louvres, decorative trims, and more

5. Why Choose Assist Work (Thailand) for A6063 Extrusion?

Assist Work (Thailand) is a trusted partner for custom aluminium extrusion using A6063 alloy. With years of experience in precision manufacturing, we provide:

- Rapid prototyping & high-volume production

- Custom extrusion die design and forming

- Surface treatment options: anodising, coating, heat treatment

- On-time delivery with strict quality standards

Whether you’re building industrial equipment or architectural structures, our team delivers aluminium components that meet both technical and aesthetic demands.

#A6063 #AluminumExtrusion #AnodizedAluminum #IndustrialAluminum #ArchitecturalAluminum #SolarFrames #AluminumProfiles #ThailandManufacturing #ExtrudedAluminum #CustomExtrusion

Company info

| Company name | ASSIST WORK (THAILAND) CO., LTD. | EMIDAS Member Number | 101168 |

|---|---|---|---|

| Country | Kingdom of Thailand | Street address |

Bangplee Samut Prakan Kingdom of Thailand |

| Telephone number | +66-2-136-6139 | Fax number | +66-2-136-6140 |

| Employees | 4,000,000 THB | Annual sales | |

| Employees | 60 | Person in charge | MAEDA : 085-669-1177 , Siriporn : 089-202-7035 |

| Type of manufacturing | Industrial machinery | ||

| Primary clients |

|

||