- Telephone number: +66-2-136-6139

- FAX: +66-2-136-6140

- Website

- Basic Info

- Equipment

- Technology & Products

- History, Philosophy & Quality

- Map / HQ

How to Plan Prototype Manufacturing Efficiently | Cut Costs and Minimize Development Risk

Category

The other

Brand name

Assist Work

Product info

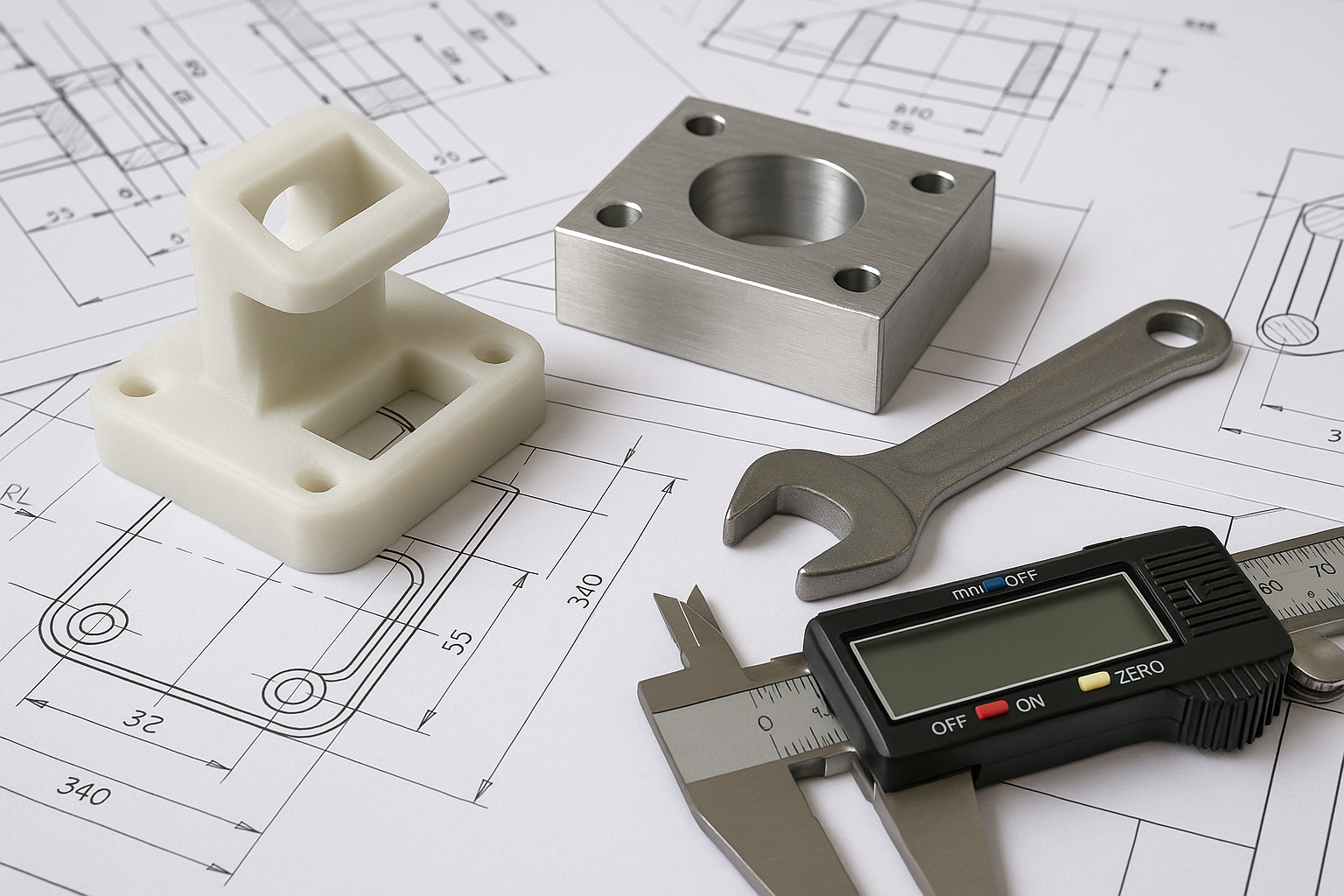

A prototype is more than just a sample—it’s a strategic step that affects cost, timeline, and product success. Learn how to plan prototype manufacturing with clarity and purpose to reduce waste and speed up development.

1. Why Prototyping Is Crucial in Industrial Development

In sectors like machinery, industrial automation, and automotive, prototypes validate design, function, and manufacturability before full-scale production. A poorly planned prototype can lead to:

- Cost overruns

- Time delays

- Functional mismatches

That’s why investing in strategic prototype planning saves both time and money in the long run.

2. Key Tips for Planning a Smart, Cost-Efficient Prototype

✅ 2.1 Define the Objective Clearly

Before sending out your drawings, ask:

- Are you testing function or form?

- Will the part be assembled, shown to clients, or used in field testing?

A well-defined objective helps align the materials, precision level, and surface finish with your budget and expectations.

✅ 2.2 Select Purpose-Based Materials

Don’t overengineer the prototype. Use lower-cost substitutes when possible. For example:

- Aluminium instead of stainless steel

- Mild steel instead of tool-grade steel

This approach delivers functionality without overspending.

✅ 2.3 Provide Complete Technical Files

Many prototype failures come from incomplete or unclear specs. Always provide:

- Tolerances

- Thread specs

- Coating or surface treatment notes

- Full 2D drawings and 3D CAD files

Clear data = less back-and-forth = faster production.

✅ 2.4 Work With a Flexible, Consultative Manufacturer

Choose a shop that can offer material advice, suggest design tweaks, and adjust processes on the fly. Flexibility is essential for R&D.

3. How to Reduce Costs and Prototype Risk

🔧 3.1 Limit the First Production Run

Start small—1 to 3 pieces. Avoid making 10+ parts before validating the design. This reduces waste and testing costs.

🔧 3.2 Schedule Buffer Time for Revisions

Prototyping is iterative. Allocate extra time for testing, redesign, and remanufacturing so your main project timeline stays on track.

🔧 3.3 Consolidate All Processes Under One Roof

Choose a manufacturer with multi-process capabilities like CNC, EDM, grinding, welding, and finishing. This saves shipping costs and reduces coordination errors.

4. Why Choose Assist Work (Thailand) for Your Prototype Manufacturing

Assist Work (Thailand) is a trusted partner for prototype production, specialising in:

- CNC machining

- Custom aluminium parts

- Engineering plastics

- Speciality metals

Our strengths include:

- Expert consultation before production

- Fast turnaround with high precision

- Support for design validation and iteration

- Full scalability from prototype to mass production

- In-house machining accuracy for real assembly conditions

→ Start your prototype project with confidence: Explore Assist Work (Thailand)

#PrototypeManufacturing #IndustrialPrototype #CNCParts #CustomMachining #RapidPrototyping #EngineeringParts #AssistWorkThailand #MetalPrototype #ProductDevelopment #MechanicalTesting

Company info

| Company name | ASSIST WORK (THAILAND) CO., LTD. | EMIDAS Member Number | 101168 |

|---|---|---|---|

| Country | Kingdom of Thailand | Street address |

Bangplee Samut Prakan Kingdom of Thailand |

| Telephone number | +66-2-136-6139 | Fax number | +66-2-136-6140 |

| Employees | 4,000,000 THB | Annual sales | |

| Employees | 60 | Person in charge | MAEDA : 085-669-1177 , Siriporn : 089-202-7035 |

| Type of manufacturing | Industrial machinery | ||

| Primary clients |

|

||