- Telephone number: +66-2-136-6139

- FAX: +66-2-136-6140

- Website

- Basic Info

- Equipment

- Technology & Products

- History, Philosophy & Quality

- Map / HQ

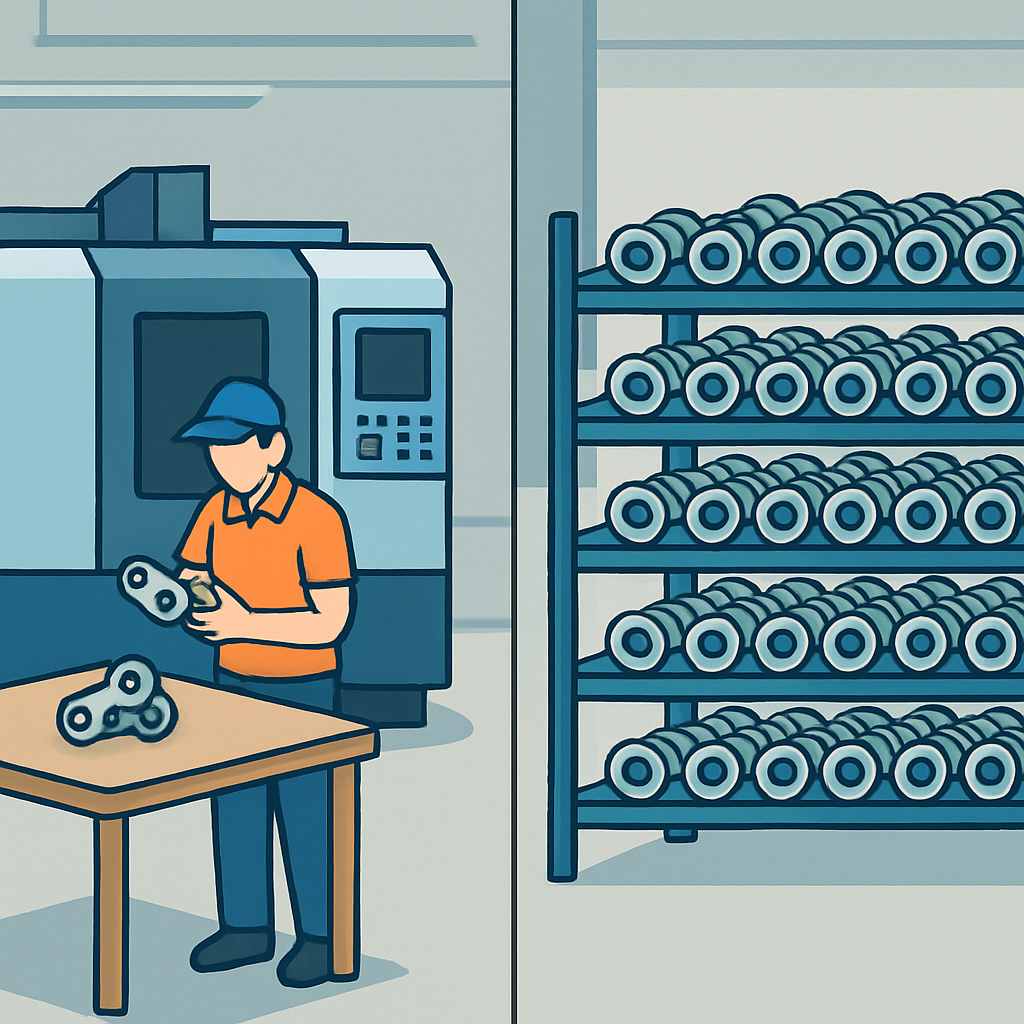

Why Choose a Manufacturer That Handles Both Mass and Low Volume Production

Category

The other

Brand name

Assist Work

Product info

Partnering with a manufacturer that handles both low-volume and mass production gives your business unmatched flexibility, helps you reduce costs, streamline development, and scale faster—without changing suppliers.

1. The Challenge of Manufacturing in a Rapidly Changing Market

In today’s industrial landscape, the ability to adapt quickly is crucial. Most projects don’t begin with mass production—they start small, often with:

- A few prototype units

- Functional tests

- Client presentations or market pilots

As the project matures, it must scale fast and reliably. Choosing a manufacturing partner that can seamlessly move from low volume to mass production gives you a strategic edge.

2. Benefits of Working with a Manufacturer That Supports Both Scales

✅ 2.1 Launch New Projects Faster

With low-volume production capabilities, you can:

- Develop prototypes quickly

- Validate function and fit before full investment

- Test market demand without committing to large orders

This approach is ideal for startups, R&D teams, and corporations launching new innovations.

✅ 2.2 Transition to Mass Production Without Disruption

Once ready, a manufacturer that also handles high-volume production ensures:

- No need to search for new vendors

- No loss of quality or time due to supplier changes

- No retooling or process adjustments that could cause delays

The result: faster time-to-market with consistent output.

✅ 2.3 Simplify Supply Chain Management

Consolidating production with one partner helps you:

- Streamline communication

- Track project status in real time

- Minimise logistics costs and coordination errors

This is especially valuable in projects with design changes or phased rollouts.

✅ 2.4 Maintain Quality from First Part to Full Batch

Working with one factory ensures:

- Consistent quality standards across all production runs

- Real-time process improvements from prototype feedback

- Less room for error when scaling up

Ideal for products that require tight tolerances, reliability, and repeatability.

3. Why Assist Work (Thailand) Is Your Ideal Manufacturing Partner

Assist Work (Thailand) supports your entire product journey—from concept to production—offering precision manufacturing across all volumes. Our expertise includes:

- CNC machining, fabrication, and welding for both low and high-volume orders

- Engineering consultation on materials, design, and cost-efficiency

- Strict quality control and testing for every unit

- Flexible production planning and on-time delivery

- Capability to scale with your growth, whether for local testing or global rollout

→ Ready to scale smart? Explore Assist Work (Thailand)

#LowVolumeProduction #MassProduction #FlexibleManufacturing #PrototypeToProduction #CNCManufacturing #IndustrialSupplier #AssistWorkThailand #ManufacturingPartner #ScaleYourProduction #IndustrialMachining

Company info

| Company name | ASSIST WORK (THAILAND) CO., LTD. | EMIDAS Member Number | 101168 |

|---|---|---|---|

| Country | Kingdom of Thailand | Street address |

Bangplee Samut Prakan Kingdom of Thailand |

| Telephone number | +66-2-136-6139 | Fax number | +66-2-136-6140 |

| Employees | 4,000,000 THB | Annual sales | |

| Employees | 60 | Person in charge | MAEDA : 085-669-1177 , Siriporn : 089-202-7035 |

| Type of manufacturing | Industrial machinery | ||

| Primary clients |

|

||