- Telephone number: +81-45-593-6116

- FAX: +81-45-593-6121

- Website

Products, Expertise & Unique Technical Info

Manufacturing category info

|

|

Thin leaf spring( Parts manufacturing / Spring ) |

|---|---|

|

|

Stainless steel material for spring( Mass production / Metal press ) |

|

|

Thickness: below 0.2 mm( Mass production / Metal press ) |

|

|

Small-size prototype manufacturing( Development and production of prototype/Small-scale production / Prototype processing ) |

|

|

Leaf spring die( Die manufacturing / Spring mold ) |

|

|

Progressive die designing (light electrical)( Designing / Mold designing ) |

|

|

Drawing metal press die designing( Designing / Mold designing ) |

Icon

Company info

| Company name | Kyowa Hearts Co., Ltd. | Website URL | |

|---|---|---|---|

| Street address |

Kohoku-ku, Yokohama Kanagawa Japan

[See map] |

Person in charge | Rumi Sakamoto |

| Telephone number | +81-45-593-6116 | Fax number | +81-45-593-6121 |

| Capital | 10,000,000 JPY | Employees | 20 |

| Annual sales | 300,000,000 JPY | EMIDAS Member Number | 1129 |

| Type of manufacturing | Telecommunication equipment / Electronic parts / Medical equipment | ||

| Main 3 products |

|

||

PR message

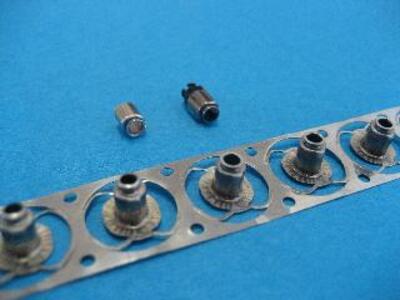

Our company is a professional group manufacturing "light, small, thin and multifunctional" parts with a mission to contribute to further quickening our customers' pace of development.

Expert Technology

We use precise progressive dies for:

1. Microfabrication (Smallest: rice grain-sized; plate width: 0.03)

2. Complex shapes, high-precision bending

3. Round shapes (both curling and drawing possible)

Proposals to help you launch products fast

Many of the fields we work in are related to mobile phones, but the most important part of our work is our development speed. During the development phase, we provide comprehensive advice regarding the questions you may have during the design process--from consultations on determining materials and product shapes to secondary processing proposals--and provide full support to launch your new products. We can offer you value because of our proposals.

Testing in as little as 3 days

We confirm the functionality of mechanism parts, particularly leaf springs (light leaf springs) by hand, which is an indispensible part of the process. Our company's testing concept is "Test by hand prior to mass production." We can handle individual parts or several hundred in a short period of time.

Mass production molds in as little as 2 weeks

We undertake full-scale manufacturing in-house, from drawing and die design to manufacturing and press mass production for light, small and thin leaf springs. We produce simple, compact, high-precision and highly durable dies. We also respond quickly to the inevitable changes and revisions made to dies during production of units.

We guarantee reliable quality with our refined products

However, when you actually make a mold, it is not unusual for some problems to occur that do not precisely represent the measurements.

This may not cause a short-term problem or become a problem during the customer's examination, but at Kyowa Hearts we try to make products for the long-term. That’s why our idea is to "guarantee reliable quality with our refined products," which we adopt as artisans, making adjustments one step at a time before entering mass production.

That leads to not only reliable product quality, but also molds with a long service life without problems.

Ensuring optimal quality and production environment quality

We acquired ISO 9001 standard in 1999. We also take the Quality Management Examination (sponsored by the Japan Standards Association), with most of our on-site employees achieving Level 3 or higher. We take this action throughout the company to realize a fusion of the Quality Management System and Japanese quality management. By providing products with optimal quality, we give the customer no cause for concern during the production process.

We also correspond to the RoHS, WEEE and other directives for production environment quality assurance.

We are now working towards acquiring the ISO 14001 Environmental Management Standard.

When you are developing a product or if you have a die but are having trouble with processing, feel free to consult with us.

Most recent update:2024-10-17

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Progressive die designing (light electrical) Progressive die designing (auto) Drawing metal press die designing |

| Designing | Product and part designing | Office equipment designing |

| Development and production of prototype/Small-scale production | Prototype processing | Small-size prototype manufacturing |

| Die manufacturing | Press die | NC data creation Progressive die Below 60 t 60 - 300 t |

| Die manufacturing | Spring mold | Designing Manufacturing Spring die part processing Leaf spring die |

| Mass production | Metal press | Stainless steel material for spring Thickness Progressive press (35 - 80 t) Progressive press (80 - 200 t) |

| Parts manufacturing | Spring | Thin leaf spring |

| Product manufacturing | Household commodity | Office equipment manufacturing |