- Telephone number: +81-564-27-1855

- FAX: +81-564-27-1856

- Website

- Basic Info

- Equipment

- Technology & Products

- Movie

- EMIDASBLOG

- Map / HQ

Products, Expertise & Unique Technical Info

Manufacturing category info

|

|

Machining (resin)( Development and production of prototype/Small-scale production / Machining ) |

|---|---|

|

|

Vacuum injection molding( Development and production of prototype/Small-scale production / Prototype processing ) |

|

|

Photoforming( Development and production of prototype/Small-scale production / Prototype processing ) |

|

|

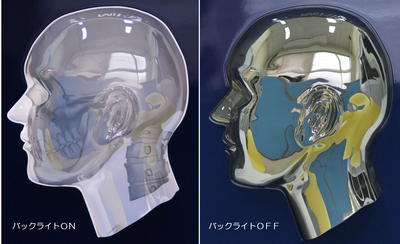

Vacuum deposition( Surface treatment / Other surface treatment ) |

|

|

Resin coating( Surface treatment / Coating ) |

|

|

Model designing( Designing / Product and part designing ) |

|

|

Plastic protocol machining( Development and production of prototype/Small-scale production / Prototype processing ) |

Icon

Company info

| Company name | INAC.CO.,LTD | Website URL | http://www.kk-inac.com/english/index.html |

|---|---|---|---|

| Street address |

Okazaki-shi Aichi Japan

[See map] |

Person in charge | SAYAKA KATO |

| Telephone number | +81-564-27-1855 | Fax number | +81-564-27-1856 |

| Capital | 10,000,000 JPY | Employees | 41 |

| Annual sales | Unregister | EMIDAS Member Number | 12389 |

| Type of manufacturing | Industrial machinery / Telecommunication equipment / Transportation equipment | ||

| Main 3 products |

|

||

| Primary clients |

|

||

PR message

Our company has been involved in planning and designing of amusement parts and toys, as well as, structural designing and manufacturing prototypes with resin and non-ferrous metals. Recent years, demands like shorter lead time, better quality, and lower cost to prototyping industry are on the rise. To answer such demands with an additional flavor, we deliver our products to each customer with 2nd hand treatments (painting, plating, ink jet, top coating etc.). In December, 2012 we have installed a vacuum plating apparatus which gave us the ability to shorten the lead time for vacuum evaporation plating.

In May, 2004, we have settled our first fully owned oversea branch, 杭州伊納可模具模型有限公司, in Zhejiang Hangzhou, China. In July, 2013, the second China base, 湖州伊納可模型科技有限公司, was established in Huzhou City, Zhejiang Province. Currently, China bases operate with total number of employees of 50 and 15 machining centers.

In 2013, we are also planning to establish Nagoya Development Center in Japan.

Most recent update:2023-09-19

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Product and part designing | Model designing External design |

| Designing | Jig and tool designing | General jig designing Mass production jig designing |

| Designing | Simulation | 3D modeling |

| Development and production of prototype/Small-scale production | Machining | General-purpose milling General-purpose lathe machining Tapping Aluminum alloy Machining (resin) Keyway milling Simultaneous 5-axis machining Milling (resin) Handles microfabrication |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC milling 5-face/5-axis machining Handles 3D processing |

| Development and production of prototype/Small-scale production | Jig manufacturing | General jig manufacturing |

| Development and production of prototype/Small-scale production | Prototype processing | Plastic protocol machining Photoforming Small-size prototype manufacturing Chassis prototype manufacturing Vacuum injection molding Model manufacturing Prototype/Small-lot molding Simplified/Molding prototype mold |

| Surface treatment | Coating | Resin coating Urethane coating Acrylic coating Lacquer coating |

| Surface treatment | Printing and others | NC engraving Hot stamping (gold embossing) |

| Surface treatment | Other surface treatment | Vacuum deposition Coating Shot blast Sound blast |

| Assembly/Inspection | Inspection | Measuring |