- Telephone number: +81-3-3601-3155

- FAX: +81-3-3604-3335

- Website

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Engineering plastic( Mass production / Plastic ) |

|---|---|

|

|

Thermoset resin( Mass production / Plastic ) |

|

|

Machining (vertical)( Development and production of prototype/Small-scale production / NC machining ) |

|

|

NC lathe machining( Development and production of prototype/Small-scale production / NC machining ) |

Icon

Company info

| Company name | Shirasaki Manufacturing Co., Ltd. | Website URL | |

|---|---|---|---|

| Street address |

Katsushika-ku Tokyo Japan

[See map] |

Person in charge | 大橋 暁 |

| Telephone number | +81-3-3601-3155 | Fax number | +81-3-3604-3335 |

| Capital | 10,000,000 JPY | Employees | 50 |

| Annual sales | 670,000,000 JPY | EMIDAS Member Number | 21378 |

| Type of manufacturing | Industrial machinery / Electronic parts | ||

| Main 3 products |

|

||

| Primary clients |

|

||

PR message

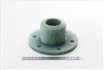

We mainly perform engineering plastic cutting, as well as molding and grinding. We have particular expertise in EG and Bakelite molding, and we have a large stock of general engineering plastic materials such as POM, MC, PE and acrylic.

We can also process nonferrous metals like aluminum, brass and titanium, as well as process with our CNC machining center's 3-D processing and CNC composite lathes to meet the various needs of our customers.

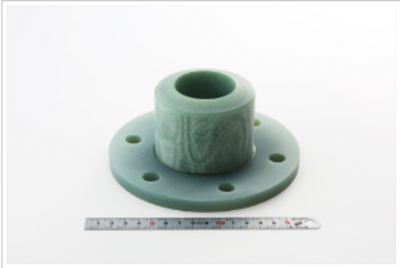

We've installed our self-developed injection molding machines and perform insert molding of stainless steel and resin. We can also work with metal. We offer our customers highly precise and reliable quality that suits your product's material qualities and shape.

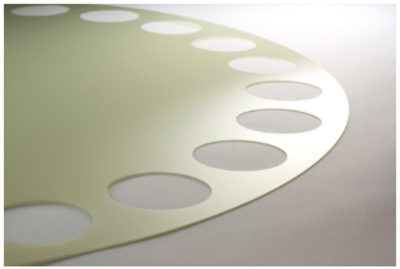

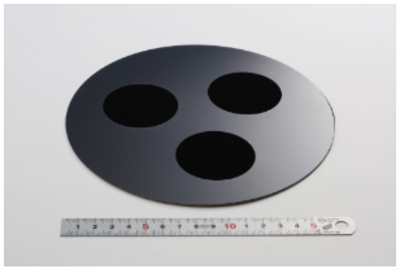

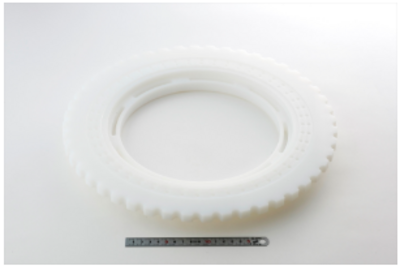

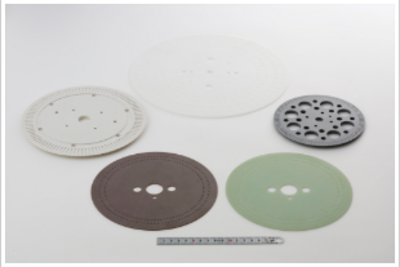

We produce lapping and polishing carriers with various materials and shapes based on our engineering plastic processing techniques. There are various kinds of lapping and polishing carriers. They are used in the process of polishing the surface of crystals, glass and silicon wagers that make up semiconductors in electronic devices such as computers and LCD TVs. Ultra-high precision is needed to polish these surfaces, so highly precise measurements are also needed for carriers.

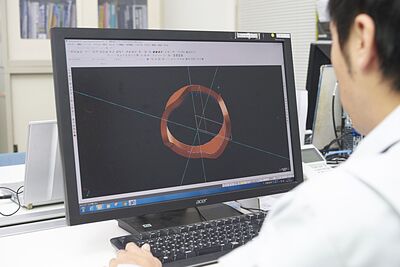

We work on various types of modification testing, including development, in which only material qualities are changed, while the prototype and shape are left intact. In particular, when making a prototype, we proactively perform highly difficult manufacturing that other companies have trouble with by making use of our processing knowhow and our self-developed special equipment.

Most recent update:2021-01-07

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Development and production of prototype/Small-scale production | Machining | General-purpose milling General-purpose lathe machining Tapping Gear hobber Magnesium alloy Machining (resin) |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC lathe machining |

| Development and production of prototype/Small-scale production | Grinding processing | Centerless grinding |

| Mass production | Plastic | PVC (polyvinyl chloride) General-purpose material PMMA (polymethyl methacrylate) Engineering plastic PBT (polybutylene terephthalate) PPS (polyphenylene sulfide) PI (polyimide) PEEK (polyetheretherketone) LCP (liquid crystal polymer) Fluororesin Thermoset resin FRP (fiber reinforced plastic) GFRP (glass fiber reinforced plastic) Urethane resin PU (polyurethane) EP (epoxy) |

| Mass production | Rubber | Compression molding |

| Surface treatment | Other surface treatment | DLC coating |

| Parts manufacturing | Machinery part | Gear manufacturing |

| Parts manufacturing | Electric board and electronic part | Rigid board |