- Telephone number: +81-53-465-0711

- FAX: +81-53-465-0714

- Website

- Basic Info

- Equipment

- Technology & Products

- Map / HQ

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

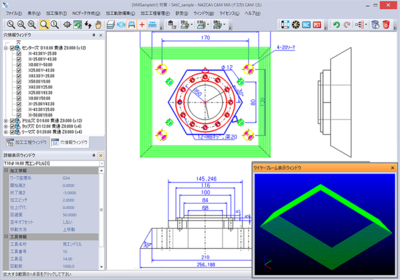

Machining (vertical)( Development and production of prototype/Small-scale production / NC machining ) |

|---|---|

|

|

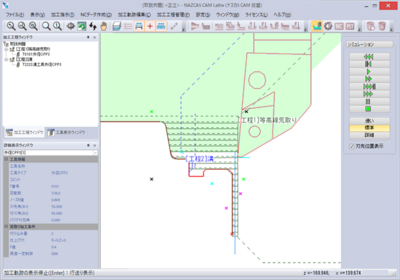

NC lathe machining( Development and production of prototype/Small-scale production / NC machining ) |

|

|

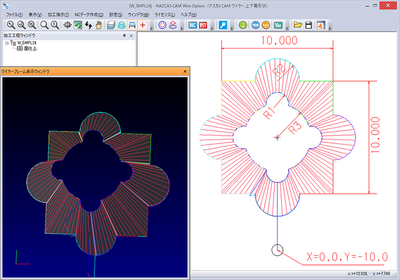

Wire electric discharge machining( Development and production of prototype/Small-scale production / Electrical discharge machine ) |

|

|

Laser processing (longer than 121.2 m)( Development and production of prototype/Small-scale production / Blank cutting ) |

|

|

Machining( Mass production / Mechanical processing ) |

|

|

NC turning machining( Mass production / Mechanical processing ) |

|

|

Cutting( Designing / Simulation ) |

Company info

| Company name | GODO SOLUTION Inc. | Website URL | https://www.godo.co.jp/ |

|---|---|---|---|

| Street address |

Hamamatsu-city, Shizuoka Japan

[See map] |

Person in charge | sales staff |

| Telephone number | +81-53-465-0711 | Fax number | +81-53-465-0714 |

| Capital | 40,520,000 JPY | Employees | 30 |

| Annual sales | Unregister | EMIDAS Member Number | 30003 |

| Main 3 products |

|

||

| Primary clients |

|

||

PR message

Godo solution is an all-around manufacturer of software for numerically-controlled (NC) machine tools, including 2D CAD/CAM platforms, processing simulation, and NC program communications. We handle everything from the development of such software to sales and support, by ourselves.

Founded in 1976, we changed our name from “Hamamatsu Godo” to “Godo solution” in 2007.

Known by the name “Nazca” and favored by customers, our products had been installed in a cumulative total of 19,600 business establishments in Japan (in terms of the whole series) as of March 2022.

We offer an assortment of numerous types of software directed to NC machine tools that address the wants and needs expressed by many production sites, reflect full consideration for safety, and make the most of our know-how for prevention of mistakes. For CAD/CAM platforms, we have overseas sales that are centered in Thailand.

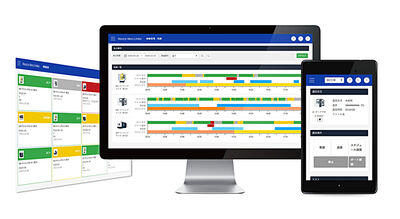

In addition, we began providing Nazca Neo Linka, an IoT system for production facilities, in 2015. We developed this system by expanding on the store of NC program communications technology we accumulated over many years.

We also accept requests for customization tailored to the particular work, and consigned software development & OEM for the manufacturing industry.

Please do not hesitate to consult us!

Most recent update:2024-04-17

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Simulation | Cutting |

| Development and production of prototype/Small-scale production | Machining | General-purpose milling General-purpose lathe machining Tapping Deep hole drilling Thread-cutting Profile milling Router machining |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC milling NC lathe machining NC vertical lathe Machining (horizontal) Handles 2.5-dimensional processing |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining |

| Development and production of prototype/Small-scale production | Blank cutting | Turret punch press processing Laser processing (longer than 121.2 m) Water jet cutter machining |

| Mass production | Mechanical processing | Machining NC milling machining NC turning machining Tapping machining Wire machining Screw cutting machining Electrical discharge machining Automatic screw machining |

| Mass production | Blank cutting | Turret punch punching Laser processing (over 1.2m) Water jet processing |

| Parts manufacturing | Bolt/Screw/Nut | Bolt/Screw/Nut manufacturing Screw manufacturing Screw manufacturing |