- Telephone number: +81-75-312-8775

- FAX: +81-75-312-0041

- Website

Products, Expertise & Unique Technical Info

Manufacturing category info

|

|

Small-size prototype manufacturing( Development and production of prototype/Small-scale production / Prototype processing ) |

|---|---|

|

|

Plastic protocol machining( Development and production of prototype/Small-scale production / Prototype processing ) |

|

|

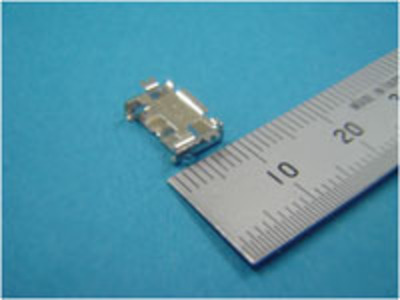

Thickness: 0.2 mm - 3.2mm( Mass production / Metal press ) |

|

|

Seam welding( Mass production / Welding / welding ) |

|

|

Bending process( Mass production / Sheet-metal processing ) |

|

|

Progressive press (35 - 80 t)( Mass production / Metal press ) |

|

|

Progressive press (80 - 200 t)( Mass production / Metal press ) |

Icon

Company info

| Company name | Saijo Inx Co., Ltd. | Website URL | |

|---|---|---|---|

| Street address |

Sakyo-ku, Kyoto Kyoto Japan

[See map] |

Person in charge | Tsutomu Takehara |

| Telephone number | +81-75-312-8775 | Fax number | +81-75-312-0041 |

| Capital | 46,000,000 JPY | Employees | 99 |

| Annual sales | 2,290,000,000 JPY | EMIDAS Member Number | 3106 |

| Type of manufacturing | Industrial machinery / Telecommunication equipment / Electronic parts | ||

| Main 3 products |

|

||

PR message

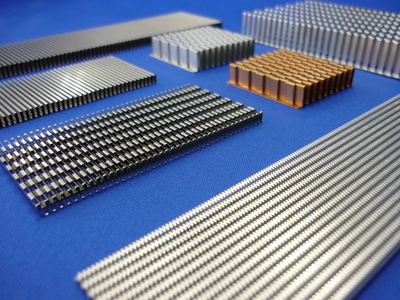

We solve customer problems and make it possible to quickly put your product on the market. We do this with our wide range of processing technology and holding facilities in our full-scale manufacturing process that goes from testing to mass production, our highly adaptive production system that can respond to vertical startups, as well as our ability to use 3-D data and CAE. We also coordinate a multitude of components with our original technology and systems with a great deal of variety, from our very own "simple mold system" testing to mass production.

Primary testing to mass production testing, micro to mid-range production presses, precision molds

Most recent update:2022-12-16

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Injection molding die Progressive die designing (light electrical) General metal press die |

| Designing | Simulation | CAE fluid analysis Thermal analysis Press Fluid-fluid heat Structure |

| Development and production of prototype/Small-scale production | Machining | Iron Stainless steel High rigid material Handles microfabrication |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining |

| Development and production of prototype/Small-scale production | Sheet-metal processing | Precision sheet metal machining Sheet metal protocol manufacturing Bending (servo) Thin wall (Thickness |

| Development and production of prototype/Small-scale production | Blank cutting | Turret punch press processing CO2 laser machining Microfabrication (laser machining ) Thin plate (below 6 mm) Stainless steel Copper/Aluminum Precision cutting |

| Development and production of prototype/Small-scale production | Welding/Adhesive bonding | CO2 welding Spot welding YAG laser machining |

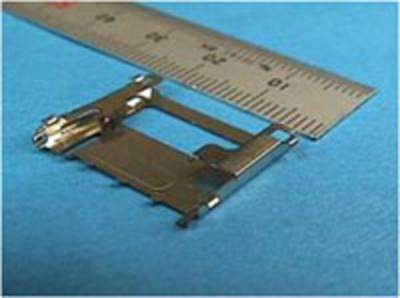

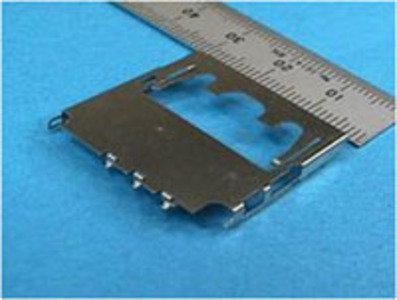

| Development and production of prototype/Small-scale production | Prototype processing | Plastic protocol machining Bending Small-size prototype manufacturing Chassis prototype manufacturing |

| Die manufacturing | Press die | Designing Manufacturing Part processing Drawing die Bending die Blanking die Progressive die Single press die Below 60 t 60 - 300 t |

| Die manufacturing | Plastic mold | Manufacturing Injection molding die Insert molding die Outsert molding die Below 60 t Thin wall injection molding die Injection molding die for microfabrication (5 mm or smaller) |

| Mass production | Metal press | Drawing Bending Blanking Iron Stainless steel Aluminum Copper Brass Phosphor bronze Titanium Plated steel plate Stainless steel material for spring Nickel Thickness Thickness Corson alloy Beryllium copper Single press (below 80 t) Single press (80 - 200 t) Progressive press (35 - 80 t) Progressive press (80 - 200 t) |

| Mass production | Plastic | Insert molding Outsert molding Engineering plastic PBT (polybutylene terephthalate) PPS (polyphenylene sulfide) LCP (liquid crystal polymer) Below 60 t Injection molding Handles small-scale production Thin wall molding |

| Mass production | Sheet-metal processing | Precision sheet metal processing Sheet metal prototype manufacturing Thin (t0.5 or less) / Small sheet metal processing Bending process |

| Mass production | Blank cutting | Turret punch punching Laser processing (over 1.2m) CO2 laser processing Etching Microfabrication (laser) Thin plate 6 mm or less stainless |

| Mass production | Welding / welding | Fiber welding Spot welding TIG welding (argon welding) Seam welding Robot welding fixing with wax YAG laser processing |

| Surface treatment | Plating/Chemical conversion treatment | Nickel (barrel) Tin (barrel) Copper (barrel) Nickel (rack) Tin (rack) Copper (rack) Gold/Silver plating Acid pickling Aldine treatment (aluminum chromate) Electroless nickel (barrel) Electroless nickel (rack) Trivalent Chromate (barrel plating) Iron Copper Brass Aluminum Stainless steel Hard chromium (rack) Titanium Degreasing Hard alumite Nickel (hoop) Gold(Hoop) Black nickel Tin (hoop) |

| Surface treatment | Cleaning | Hydrocarbon cleaning |

| Surface treatment | Polishing/Lapping | Electropolishing Chemical polishing |

| Surface treatment | Printing and others | Silk screen printing |

| Surface treatment | Heat treatment | Annealing Quenching |

| Surface treatment | Barrel polishing | Barrel finishing (rotation) |

| Assembly/Inspection | Inspection | Metal press Plastic |

| Assembly/Inspection | Side job processing | Manual labor |

| Auto parts manufacturing | Engine | Muffler Radiator parts |