- Telephone number: +81-294-53-3821

- FAX: +81-294-53-6839

- Website

Press Specialist Manufacturer – One-Stop Production

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Progressive die designing (auto)( Designing / Mold designing ) |

|---|---|

|

|

Drawing( Mass production / Metal press ) |

|

|

Press forging( Mass production / Forging ) |

|

|

Shaving die( Die manufacturing / Press die ) |

|

|

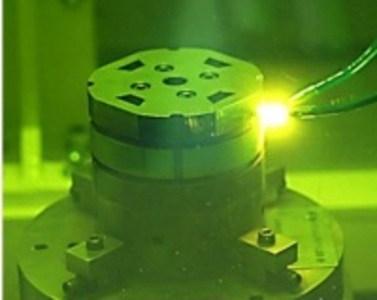

YAG laser machining( Development and production of prototype/Small-scale production / Blank cutting ) |

|

|

Transfer press die( Die manufacturing / Press die ) |

|

|

NC cylindrical grinding( Mass production / Grinding processing ) |

|

|

Machining/Handles small-scale production (order from 1 piece)( Development and production of prototype/Small-scale production / Machining ) |

|

|

Progressive press (80 - 200 t)( Mass production / Metal press ) |

|

|

Small-size prototype manufacturing( Development and production of prototype/Small-scale production / Prototype processing ) |

Icon

Company info

| Company name | Onuki Kogyosho Co., Ltd | Website URL | http://www.ohnuki.co.jp |

|---|---|---|---|

| Street address |

Hitachi - shi Ibaraki Japan

[See map] |

Person in charge | Hiroto Ohnuki |

| Telephone number | +81-294-53-3821 | Fax number | +81-294-53-6839 |

| Capital | 10,000,000 JPY | Employees | 60 |

| Annual sales | 600,000,000 JPY | EMIDAS Member Number | 34417 |

| Type of manufacturing | Industrial machinery / Electronic parts / Medical equipment | ||

| Main 3 products |

|

||

| Primary clients |

|

||

PR message

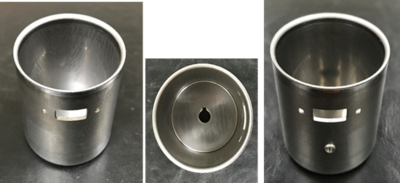

Mold Manufacturing & Press Processing

We specialize in the production of progressive dies, transfer dies, and single-shot dies, utilizing advanced stamping, bending, deep drawing, and forging technologies.

By transitioning from traditional machining-based manufacturing to press processing, we offer cost reduction, increased productivity, and enhanced quality stability.

Materials We Handle:

Stainless steel, copper, brass, nickel silver, phosphor bronze, aluminum, iron, etc.

Production Capabilities:

Material Thickness: 0.1mm – 5.0mm

Press Machines: 35 tons – 400 tons

Laser Welding Machines: 2 units

We take pride in our expertise in deep drawing of stainless steel and forging of steel sheets, aluminum, and copper.

Currently, we specialize in the mass production of components for automotive, industrial equipment, and semiconductor manufacturing devices.

For small-tonnage presses, we focus on the mass production of terminal components, primarily for bending and stamping applications.

Laser Welding Services:

Available as a standalone service or in combination with press processing.

Currently handling stainless steel and iron welding.

Most recent update:2026-02-27

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Forging die designing Injection molding die Progressive die designing (light electrical) Progressive die designing (auto) Drawing metal press die designing Transfer press die designing General metal press die Extrusion molding die designing 3D modeling (press) 3D modeling (plastic) NC data creation (press) NC data creation (plastic) |

| Designing | Jig and tool designing | General jig designing Welding jig designing Mass production jig designing |

| Designing | Test | Specimen processing Destructive test Chemical analysis Investigative research |

| Designing | Simulation | CAE fluid analysis Forging Heat treatment Press Cutting |

| Development and production of prototype/Small-scale production | Machining | General-purpose milling General-purpose lathe machining Deep hole drilling Rolling Thread-cutting Profile milling Straightening Machining/Handles small-scale production (order from 1 piece) Iron Stainless steel High rigid material Aluminum alloy Copper alloy Titanium alloy Nickel alloy Molybdenum alloy Machining (resin) Sintered metal Keyway milling Automatic lathe Bench lathe machining Milling (resin) Air chuck equipment Lathe machining (resin) Casting Handles microfabrication Titanium Brass Diamond |

| Development and production of prototype/Small-scale production | NC machining | NC milling |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining Micro hole machining Electric discharge machining |

| Development and production of prototype/Small-scale production | Sheet-metal processing | Sheet metal protocol manufacturing |

| Development and production of prototype/Small-scale production | Blank cutting | YAG laser machining |

| Development and production of prototype/Small-scale production | Grinding processing | NC plane grinding NC cylindrical grinding Plane grinding Form grinding Cylindrical grinding Cylindrical mirror grinding Internal grinding Centerless grinding Thread grinding NC internal grinding Magnetic Abrasive |

| Development and production of prototype/Small-scale production | Welding/Adhesive bonding | TIG welding (argon welding) Robot welding YAG laser machining |

| Development and production of prototype/Small-scale production | Jig manufacturing | General jig manufacturing Welding jig manufacturing Mass production jig manufacturing Jig and tool manufacturing |

| Development and production of prototype/Small-scale production | Prototype processing | Plastic protocol machining Punching Welding Bending Small-size prototype manufacturing Chassis prototype manufacturing Vacuum injection molding Prototype/Small-lot molding prototype mold |

| Die manufacturing | Press die | Designing Manufacturing Part processing Plate machining Die set machining NC data creation Drawing die Bending die Blanking die Forming die Shaving die Progressive die Transfer press die Single press die |

| Die manufacturing | Rubber mold | Part processing Blanking die Packing-related products binoculars and optical products Home electrical appliances Mobile phones Light electrical/earthing rubber Medical |

| Mass production | Metal press | Drawing Bending Blanking Forming Transfer press (below 80 t) Iron Stainless steel Aluminum Copper Brass Phosphor bronze Plated steel plate Stainless steel material for spring Nickel Thickness Thickness Thickness φ0.6mm - φ9.0mm Diameter Single press (below 80 t) Single press (80 - 200 t) Progressive press (35 - 80 t) Progressive press (80 - 200 t) |

| Mass production | Forging | Press forging Iron Aluminum Brass Others Below 500 g 500 g - 5 kg |

| Mass production | Grinding processing | NC plane grinding NC cylindrical grinding Plane grinding Form grinding Cylindrical grinding Cylindrical mirror grinding Internal grinding Centerless grinding Thread grinding NC internal grinding Magnetic Abrasive |

| Mass production | Welding / welding | Fiber welding Spot welding YAG laser processing Impulse welding Vibration welding |

| Surface treatment | Plating/Chemical conversion treatment | Nickel (barrel) Tin (barrel) Solder (barrel) Copper (barrel) Chromium (barrel) Black chromium (barrel) Zinc (barrel) Chromate (general) Rhodium Electroless copper (barrel) Nickel (rack) Tin (rack) Copper (rack) Gold/Silver plating Chromium (rack) Black chromium (rack) Zinc (rack) Alumite (anode oxidation) Nickel chromium (rack) Acid pickling Aldine treatment (aluminum chromate) Parkerizing (phosphate film) Electroless nickel (barrel) Electroless copper (rack) Electroless nickel (rack) Chemical conversion coating Tin-zinc alloy plating (rack) Baking (hydrogen embrittling) Trivalent Chromate (barrel plating) Iron Copper Brass Aluminum Stainless steel Other anti-rust treatments Titanium Magnesium Degreasing Black oxide finish Colored alumite Hard alumite Hot-dip galvanizing (small-size Hot-dip galvanizing (mid-size Hot-dip galvanizing (large-size Dacrotizing Hot-dip aluminum plating Unichromate (white) Black chromate (black/green) Colored chromate (multi-color) Black nickel Hard alumite (large) |

| Surface treatment | Cleaning | Hydrocarbon cleaning Ultrasonic cleaning |

| Surface treatment | Lap polishing | Lap mirror polishing |

| Surface treatment | Barrel polishing | Barrel finishing (vibration) |

| Assembly/Inspection | Assembly | Auto parts assembly |

| Assembly/Inspection | Inspection | Metal press Forging Measuring |

| Parts manufacturing | Spring | Terminal spring |

| Auto parts manufacturing | Drive system part | Clutch Transmission Steering device Brake parts |

| Auto parts manufacturing | Engine | Cooling system Ignition system Fuel system Muffler Radiator parts |