- Telephone number: +81-78-995-3393

- FAX: +81-78-995-3390

- Website

- Basic Info

- Equipment

- Technology & Products

- Movie

- EMIDASBLOG

- Map / HQ

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

FRP (fiber reinforced plastic)( Mass production / Plastic ) |

|---|---|

|

|

GFRP (glass fiber reinforced plastic)( Mass production / Plastic ) |

|

|

CFRP (carbon fiber reinforced plastic)( Mass production / Plastic ) |

|

|

Thermoset resin( Mass production / Plastic ) |

|

|

EP (epoxy)( Mass production / Plastic ) |

|

|

Machining (resin)( Development and production of prototype/Small-scale production / Machining ) |

|

|

Lathe machining (resin)( Development and production of prototype/Small-scale production / Machining ) |

|

|

PF (phenol-formaldehyde)( Material / Plastic material distribution ) |

|

|

Ceramic( Development and production of prototype/Small-scale production / Machining ) |

|

|

Ceramic material( Material / Specialized material distribution ) |

Icon

Company info

| Company name | YUTAKA CORPORATION | Website URL | https://yutakasangyo.co.jp/english/index.html |

|---|---|---|---|

| Street address |

Kobe City Hyogo Japan

[See map] |

Person in charge | Masahiro Toyoda |

| Telephone number | +81-78-995-3393 | Fax number | +81-78-995-3390 |

| Capital | 10,000,000 JPY | Employees | 14 |

| Annual sales | 684,000,000 JPY | EMIDAS Member Number | 35953 |

| Type of manufacturing | Industrial machinery / Electronic parts / Transportation equipment | ||

| Main 3 products |

|

||

PR message

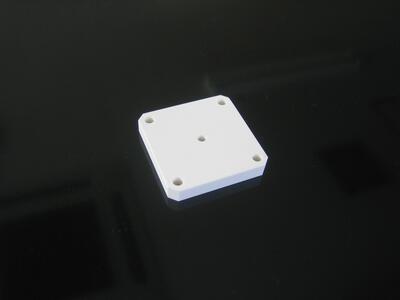

We are experts in manufacturing and supplying plastics, ceramics and heat(thermal)insulation/heat(thermal) resistant materials products mainly for machinery parts.

Our product line encompasses a wide range of plastics, ceramics and heat insulation(thermal insulation) materials and we are especially adept at using materials that are difficult to machine including the following;

1.Composite of glass fiber or carbon fiber and plastics (FRP, GFRP and CFRP).

2.Heat insulation(thermal insulation) and heat resistant materials (rigid heat insulation boards that are generally made of glass fiber, cement and mica as the main raw material)

3.Fine ceramics

Our extensive knowledge of various plastics, ceramics and heat insulation(thermal insulation) materials properties brings customers ideal solutions including optimal material selection.

Most recent update:2025-09-16

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Material | Specialized material distribution | Ceramic material |

| Material | Plastic material distribution | PVC (polyvinyl chloride) ABS resin PP (polypropylene) PE (polyethylene) PS (polystyrene) PMMA (polymethyl methacrylate) PA (nylon/polyamide) PC (polycarbonate) PET (polyethylene terephthalate) PPE (polyphenyl ether) POM (polyoxymethylene) PBT (polybutylene terephthalate) PPS (polyphenylene sulfide) PI (polyimide) PEEK (polyetheretherketone) LCP (liquid crystal polymer) Fluororesin PF (phenol-formaldehyde) FRP (fiber reinforced plastic) GFRP (glass fiber reinforced plastic) Urethane resin PU (polyurethane) Elastomer EP (epoxy) PES (polyethersulfone) |

| Development and production of prototype/Small-scale production | Machining | General-purpose milling General-purpose lathe machining Tapping Planer machining Deep hole drilling Gear hobber Thread-cutting Machining/Handles small-scale production (order from 1 piece) Ceramic Machining (resin) Keyway milling Router machining Milling (resin) Lathe machining (resin) Handles microfabrication Handles microfabrication |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC lathe machining Combined lathe machining Handles 2.5-dimensional processing Handles 3D processing |

| Development and production of prototype/Small-scale production | Blank cutting | Ceramic Acrylic PI (polyimide) Other resins |

| Development and production of prototype/Small-scale production | Grinding processing | NC plane grinding NC cylindrical grinding Plane grinding Form grinding Cylindrical grinding Jig grinding Internal grinding Centerless grinding NC internal grinding Rotary grinding |

| Development and production of prototype/Small-scale production | Welding/Adhesive bonding | Plastic bonding Other bonding methods |

| Development and production of prototype/Small-scale production | Jig manufacturing | General jig manufacturing Mass production jig manufacturing Jig and tool manufacturing |

| Development and production of prototype/Small-scale production | Prototype processing | Plastic protocol machining Punching Bending Small-size prototype manufacturing Porous plastic prototype |

| Mass production | Mechanical processing | Machining NC turning machining Complex turning machining Gear cutting machining Micro-hole machining Ceramic Turning machining(plastic) |

| Mass production | Plastic | PVC (polyvinyl chloride) General-purpose material PMMA (polymethyl methacrylate) Engineering plastic PBT (polybutylene terephthalate) PPS (polyphenylene sulfide) PI (polyimide) PEEK (polyetheretherketone) LCP (liquid crystal polymer) Fluororesin Thermoset resin FRP (fiber reinforced plastic) GFRP (glass fiber reinforced plastic) Urethane resin PU (polyurethane) Elastomer PES (polyethersulfone) FRP molding (hand lay-up/spray lay-up) EP (epoxy) CFRP (carbon fiber reinforced plastic) auto-clave) SMC) Ceramic injection (CIM) |