- Telephone number: +81-78-995-3393

- FAX: +81-78-995-3390

- Website

- Basic Info

- Equipment

- Technology & Products

- Movie

- EMIDASBLOG

- Map / HQ

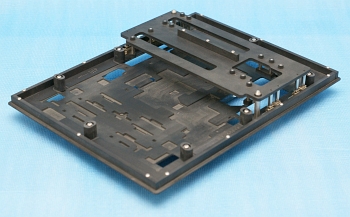

RICOCEL ES-3261A

Industry

Automobile (mass production)

Light electrical/Home electrical appliance

Manufacturing facilities

Specifications

- Materials:Thermosetting resin

- Lots:1 - No upper limit

- Precision:0.1 mm - 1/100 mm

Conventional technologies/differences from other companies

RICOCEL ES-3261A is a high heat resistant glass fiber epoxy resin laminated board for solder pallet.

Component mounting by automatic soldering machine is performed through two kind of work processes.

Generally, it is performed in the order of reflow soldering to wave soldering.

At the wave soldering process, it is necessary to apply solder only to soldering part, with the components mounted by reflow soldering being protected.

RICOCEL is the tool used in the process of wave soldering.

RICOCEL has pockets to protect the pre-mounted components and has through-holes to apply solder only to soldering spots.

Advantages of using solder pallet

Yield : Reduction of defective soldering

Masking process : Setting on pallet

Line width adjustment : Standardized

Thermal stress to electronic components : Small

・Size of Blank Material

Thickness : 3~15mm

Length X Width : 1000X1200 mm 1200X2000 mm

Company info

| Company name | YUTAKA CORPORATION | EMIDAS Member Number | 35953 |

|---|---|---|---|

| Country | Japan | Street address |

Kobe City Hyogo Japan |

| Telephone number | +81-78-995-3393 | Fax number | +81-78-995-3390 |

| Employees | 10,000,000 JPY | Annual sales | 684,000,000 JPY |

| Employees | 14 | Person in charge | Masahiro Toyoda |

| Type of manufacturing | Industrial machinery / Electronic parts / Transportation equipment | ||