- Telephone number: +81-294-36-0300

- FAX: +81-294-34-5947

- Website

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Shaving die( Die manufacturing / Press die ) |

|---|---|

|

|

Transfer press (200 - 500 t)( Mass production / Metal press ) |

|

|

Progressive press (80 - 200 t)( Mass production / Metal press ) |

|

|

Shaving( Mass production / Metal press ) |

|

|

Transfer press (80 - 200 t)( Mass production / Metal press ) |

|

|

Progressive die designing (auto)( Designing / Mold designing ) |

|

|

Transfer press die designing( Designing / Mold designing ) |

|

|

Transfer press die( Die manufacturing / Press die ) |

|

|

Metal press( Assembly/Inspection / Inspection ) |

Icon

Company info

| Company name | Seki Press Co., Ltd. Main Factory | Website URL | http://www.sekipress.jp/ |

|---|---|---|---|

| Street address |

Hitachi Ibaraki Japan

[See map] |

Person in charge | 関 正克 |

| Telephone number | +81-294-36-0300 | Fax number | +81-294-34-5947 |

| Capital | 42,000,000 JPY | Employees | 85 |

| Annual sales | 1,200,000,000 JPY | EMIDAS Member Number | 39115 |

| Type of manufacturing | Heavy electric machinery / Transportation equipment / Electrical component for transportation equipment | ||

| Main 3 products |

|

||

| Primary clients |

|

||

PR message

At Seki Press, we use a variety of our own tools to quickly respond to a wide range of customer requests, from high-mix, low-volume manufacturing to ultra-high-volume production.

Check out our website for more information about our exclusive construction approach technology.

≪Original Processing of Seki Press≫

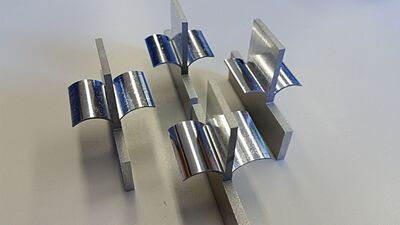

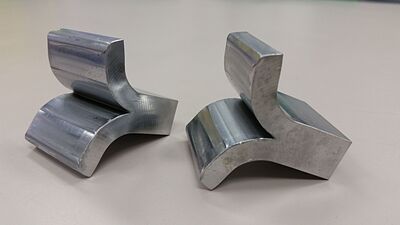

■ Warisaki Method (The Method of Splitting)

Obtained patents in Japan and 15 European countries (Switzerland/Germany/Denmark/Finland/France/United Kingdom/Hungary/Norway/Sweden/Czech Republic/Spain/Italy/Poland/Slovakia/Austria), United States, China, South Korea, India, Taiwan, Vietnam, etc.

◆ Splitting, Internal Split, Peripheral Split, Split Joining ◆

The world's first plastic working method that divides plates and coils in a progressive die to realize three-dimensional integrally formed parts.

Newly proposed as a method of joining dissimilar metals by applying the Warisaki Method or the splitting process.

From cutting, forging, and die-casting, 3D-shaped products can be completed with metal presses to reduce costs and shorten lead time.

★ Small-and-Medium Enterprise Director's Award, Ibaraki Industry Grand Prize, Joyo Business Award Grand Prize ★

★Approved by 300 Small-and-Medium Enterprises and Small Businesses ★

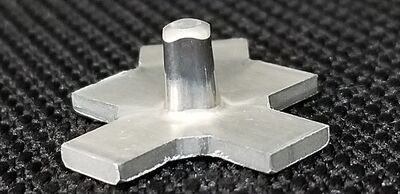

■ Tulum method (solid protrusion formation method)

May 2019 Japan patent acquired

May 2020 Taiwan patent acquired

Achieving a solid protrusion in one process for plate materials

■ Factory dedicated to aluminum

April 2018 Construction of a factory dedicated to aluminum

Separated from general materials to reduce foreign matter and improve quality.

*Material + press + degreasing + shipping inspection + packing and shipping*

■ Local production of automatic equipment

We design and manufacture visual inspection equipment, distribution equipment, and automation equipment related to production and quality from software.

We work to improve production technology with the aim of streamlining integrated production.

≪Industrial video scopes for sale≫

■A wide variety of probe options are available for low-cost, high-performance industrial video scopes.

■Furthermore, a rental copy is available for free; kindly view it and try it out

■Visit our website for more information

Most recent update:2025-04-07

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Progressive die designing (light electrical) Progressive die designing (auto) Drawing metal press die designing Transfer press die designing General metal press die |

| Designing | Jig and tool designing | General jig designing Welding jig designing Mass production jig designing |

| Development and production of prototype/Small-scale production | Machining | General-purpose milling Tapping Spinning Machining/Handles small-scale production (order from 1 piece) |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining |

| Development and production of prototype/Small-scale production | Welding/Adhesive bonding | Spot welding TIG welding (argon welding) |

| Development and production of prototype/Small-scale production | Prototype processing | Punching Welding Bending |

| Die manufacturing | Press die | Designing Manufacturing Part processing Drawing die Bending die Blanking die Forming die Shaving die Progressive die Transfer press die Single press die Press robot die Below 60 t 60 - 300 t Compound die |

| Mass production | Metal press | Drawing Bending Blanking Forming Fine blanking Shaving Iron Stainless steel Aluminum Copper Brass Phosphor bronze Plated steel plate Stainless steel material for spring Nickel Thickness Thickness Thickness Transfer press (80 - 200 t) Transfer press (200 - 500 t) Single press (below 80 t) Single press (80 - 200 t) Progressive press (35 - 80 t) Progressive press (80 - 200 t) |

| Surface treatment | Plating/Chemical conversion treatment | Chromate (general) Acid pickling Iron Stainless steel |

| Surface treatment | Coating | Air-spray coating Powder coating Electrodeposition coating |

| Surface treatment | Printing and others | Silk screen printing |

| Surface treatment | Heat treatment | Normalizing Annealing Quenching Austempering |

| Surface treatment | Barrel polishing | Barrel finishing (vibration) Barrel finishing (rotation) |

| Assembly/Inspection | Assembly | Precision equipment assembly Office equipment assembly Auto parts assembly Construction component assembly |

| Assembly/Inspection | Inspection | Metal press |

| Parts manufacturing | Spring | Thin leaf spring Terminal spring |