- Telephone number: +81-295-53-2109

- FAX: +81-295-53-1228

- Website

Products, Expertise & Unique Technical Info

Manufacturing category info

|

|

Blanking die( Die manufacturing / Press die ) |

|---|---|

|

|

Blade manufacturing ( Parts manufacturing / Other parts ) |

|

|

General jig manufacturing( Development and production of prototype/Small-scale production / Jig manufacturing ) |

|

|

Combined press-joining ( Mass production / Metal press ) |

|

|

Medical equipment manufacturing( Product manufacturing / Medical equipment manufacturing ) |

|

|

Small-size prototype manufacturing( Development and production of prototype/Small-scale production / Prototype processing ) |

|

|

Plane grinding( Mass production / Grinding processing ) |

|

|

Mirror polishing( Surface treatment / Polishing/Lapping ) |

|

|

General jig designing( Designing / Jig and tool designing ) |

|

|

Thomson punch( Die manufacturing / Cutting dies ) |

Icon

Company info

| Company name | NOGAMIGIKEN CO., LTD. | Website URL | http://www.nogami-gk.co.jp/en_gaiyou.htm |

|---|---|---|---|

| Street address |

Hitachiomiya City Ibaraki Japan

[See map] |

Person in charge | support |

| Telephone number | +81-295-53-2109 | Fax number | +81-295-53-1228 |

| Capital | 10,000,000 JPY | Employees | 62 |

| Annual sales | Unregister | EMIDAS Member Number | 43653 |

| Type of manufacturing | Jigs and tools / Industrial machinery | ||

| Main 3 products |

|

||

| Primary clients |

|

||

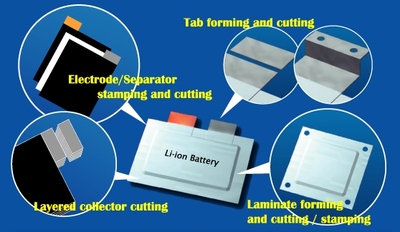

PR message

We design and produce super precision jigs (Film boring jigs, a variety of cutting jigs, and precision devices). We operate precision metal stamping (t0.01 ~ thin board connecting springs, complex parts inside molding dies, electronic parts, and film boring). With ISO9001 certified, we supply customers with high-quality products.

***For more details, please check the video about our plant on our homepage. ***

The source of our mission, goal, and dream is to be “devoted to doing our business of MONODZUKURI with a great determination and good faith, creating valuable products and

services, and making a contribution to society.”

We believe that “a corporation is kept alive by the society.” For example, even if a company obtains cutting edge technologies, there is no point for their existence without contributing to customers and the society.

Our mission is to supply customers with satisfaction, reliable products and services by retaining the tradition of founder’s diligence and craftsmanship of precision grinding while adding ability to develop and design better products. .In orders to accomplish our mission, we frequently challenge ourselves to the limit.

Most recent update:2025-11-12

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | General metal press die |

| Designing | Jig and tool designing | General jig designing Mass production jig designing |

| Designing | Test | Specimen processing |

| Designing | Simulation | Press Cutting |

| Development and production of prototype/Small-scale production | Grinding processing | NC plane grinding Form grinding |

| Development and production of prototype/Small-scale production | Jig manufacturing | General jig manufacturing Mass production jig manufacturing |

| Development and production of prototype/Small-scale production | Prototype processing | Punching Bending Small-size prototype manufacturing prototype mold |

| Die manufacturing | Press die | Designing Manufacturing Blanking die Progressive die Below 60 t Compound die |

| Die manufacturing | Cutting dies | Thomson punch Cutting blade cutting die Corrosion blade cutting die |

| Mass production | Metal press | Bending Blanking Forming Shaving Coining Iron Stainless steel Aluminum Copper Brass Phosphor bronze Titanium Plated steel plate Stainless steel material for spring Nickel Thickness Thickness Combined press-joining Beryllium copper Progressive press (35 - 80 t) |

| Mass production | Grinding processing | Plane grinding Form grinding Profile grinding Double-sided grinding |

| Surface treatment | Polishing/Lapping | Mirror polishing |

| Surface treatment | Lap polishing | Lap polishing Lap mirror polishing Single-face lapping and polishing |

| Surface treatment | Other surface treatment | Coating Teflon coating Ionized plating DLC coating |

| Assembly/Inspection | Assembly | Precision equipment assembly |

| Parts manufacturing | Spring | Thin leaf spring Terminal spring Leaf spring Carbon steel Stainless steel Copper alloy |

| Parts manufacturing | Other parts | Blade manufacturing |

| Product manufacturing | Production property | Other industrial machinery manufacturing Blade manufacturing Semiconductor manufacturing equipment manufacturing |

| Product manufacturing | Medical equipment manufacturing | Medical equipment manufacturing |

![Handheld punch with Visual Checking [film hole punching equipments]](/temp/400_300_8ea537743d270a3646b2dd47ad95879f6e18e5ff.jpg)

![[Polishing]Precision Mold・Automatic Machine Part Manufacturing [Spot・Repeat On Demand]](/temp/400_300_21d00c59ee9a0503c086761467fe052b22afb2fe.jpg)

![Handheld punch with Visual Checking [film hole punching equipments]](/temp/110_70_8ea537743d270a3646b2dd47ad95879f6e18e5ff.jpg)

![[Polishing]Precision Mold・Automatic Machine Part Manufacturing [Spot・Repeat On Demand]](/temp/110_70_21d00c59ee9a0503c086761467fe052b22afb2fe.jpg)