- Telephone number: +81-143-55-5293

- FAX: +81-143-55-5295

- Website

- Basic Info

- Equipment

- Technology & Products

- Movie

- History, Philosophy & Quality

- EMIDASBLOG

- Map / HQ

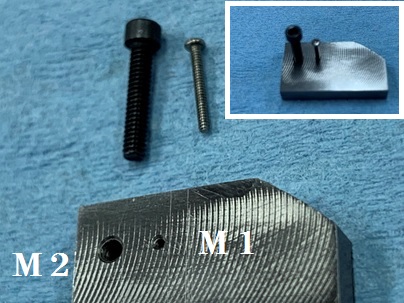

Drilling screw holes into Niobium material (M1, M2)

Industry

Medical equipment

Environmental equipment

Specifications

- Materials: ---

- Lots:1 - 100 lots

- Precision:Plus or minus 0.1 mm

Conventional technologies/differences from other companies

Drilling screw holes into niobium material (M1, M2)

Niobium becomes a superconductor at the highest critical temperature (9.2K), and its properties are being utilized for industrial purposes.

It is anticipated that it will be used in a wide range of applications, including MRI and NMR devices, solenoid coils used in nuclear fusion reactors, and superconducting accelerators that are expected to shed light on the Big Bang.

This time, we attempted to process screw holes, which are essential for mounting to such devices.

However, we did not understand its processing characteristics, and initially we had difficulty with issues such as protrusions on the back surface.

By reconsidering the processing method and changing the processing conditions, we were able to successfully process to a depth of 2 mm with M1 and M2!

Material: Niobium

Machining shape: Screw hole (M1, M2)

Depth: 2mm

Using Machine: Machining Center

We are also challenging with machining Nb.

Especially, machining Nb screws.

WEB page of <Electric wire cut to Nb (Niobium)> is below:

https://en.nc-net.com/company/46129/product/detail/78015/

Company info

| Company name | Chimera Co., Ltd. | EMIDAS Member Number | 46129 |

|---|---|---|---|

| Country | Japan | Street address |

Muroran Hokkaido Japan |

| Telephone number | +81-143-55-5293 | Fax number | +81-143-55-5295 |

| Employees | 28,000,000 JPY | Annual sales | |

| Employees | 100 | Person in charge | H. OHSHIRO |

| Type of manufacturing | Audio-video equipment / Office automation equipment / Electronic parts | ||