- Telephone number: +81-76-276-0711

- FAX: +81-76-276-0727

- Website

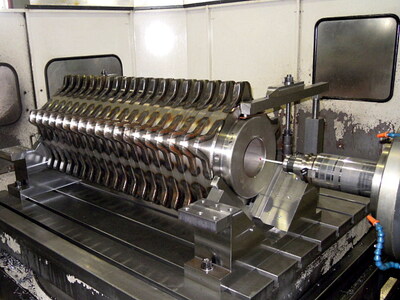

Nakagawa Inc. specializes in large-scale precision machining.

●Machining capabilities up to 14 meters in length

●Comprehensive services from material procurement to assembly

●Expertise in difficult-to-cut materials like duplex stainless steel and titanium

●Flexibility to handle small-lot production

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

NC lathe machining( Development and production of prototype/Small-scale production / NC machining ) |

|---|---|

|

|

Machining (vertical)( Development and production of prototype/Small-scale production / NC machining ) |

|

|

5-face/5-axis machining( Development and production of prototype/Small-scale production / NC machining ) |

|

|

Thread-cutting( Development and production of prototype/Small-scale production / Machining ) |

|

|

Boring milling ( Development and production of prototype/Small-scale production / NC machining ) |

|

|

Industrial machinery assembly( Assembly/Inspection / Assembly ) |

|

|

Stainless steel( Development and production of prototype/Small-scale production / Machining ) |

Icon

Company info

| Company name | Nakagawa Inc. | Website URL | https://www.nakagawa-t.com |

|---|---|---|---|

| Street address |

Hakusan-shi Ishikawa Japan

[See map] |

Person in charge | Koshin Norihiko |

| Telephone number | +81-76-276-0711 | Fax number | +81-76-276-0727 |

| Capital | 30,000,000 JPY | Employees | 24 |

| Annual sales | 438,000,000 JPY | EMIDAS Member Number | 48866 |

| Type of manufacturing | Machine tools / Industrial machinery / Transportation equipment | ||

| Main 3 products |

|

||

PR message

Please leave "long and large machining" to us!

We are widely compatible with CNC lathes that can process up to 14m, machining centers (4m), five-face machining centers (7m), etc. We also have many track record especially in long shaft processing.

"Difficult-to-cut material processing"

We have a track record of processing difficult-to-cut materials such as Inconel, duplex stainless steel, and high-hardness materials.

"Assembly"

We cover production lines for damping equipment and mobile phones, melting furnaces, cylinders for large presses, etc.

* 9 promises of Nakagawa Inc. *

1. Trust of "93 years since establishment"

Our company was founded in 1918. We are one of the longest-established ironworks in Hokuriku region. The secret is honesty. The current president of the third generation has taken over that attitude and will never slacken on customer satisfaction.

And from now on, we will continue to connect people, connect companies, and face metal earnestly in the Hokuriku region.

2. Direct transaction records with major companies

Although we are a small company with less than 30 people, we do business directly with top-tier major companies such as Komatsu Ltd., Kobe Steel, Ltd., Torishima Pump Mfg Co., Ltd., Hitachi, Ltd., Mitsubishi Heavy Industries, Ltd., etc. We are highly evaluated by the attitude toward work and the management ability.

3. Proper and thorough estimation

We offer high credible estimation. Please contact our staff Nakagawa and Koshida.

4. Long-term relationship

Our craftsmen are young (30s and 40s) and highly skilled. We are able to keep in touch with customers for a long time.

5. Extensive mechanical equipment

We handle a wide range of machining, from long machining to palm-sized parts. We assure that we can meet customer's difficult requests, such as CNC lathes up to 14 m in length, five-face machines with 7 m beds, and gun drill machines that can handle depths of 2 m, etc.

6. Mass production from low-cost material arrangement to assembly is possible

Please leave low-cost material arrangement to us. We can purchase directly from JFE Steel Corporation, and in many cases it can be supplied cheaper than trader in Asian countries. In collaboration with Komatsu-related companies, we deliver products with reassurance.

7. VA proposal

We think through to process low-cost and high quality products. The improvements derived from many years of processing know-how will surely be useful to customers. We are sure that we can help with alternative materials, man-hour reduction, easy-to-process shape proposals, etc.

8. Good at "difficult-to-cut material processing"

We have been aggressively challenging and overcoming difficult-to-cut materials such as Inconel and duplex stainless steel. The innovative processing method was born from our veteran craftsmen.

9. Handle small lots and prototype

We have produced a wide variety of products in small lots for a long time, even for 1 or 2 pieces. Please do not hesitate to contact us.

Nakagawa Inc.

2024,Kurabemachi,Hakusan-shi, Ishikawa, Japan

Website: https://www.nakagawa-t.com

Most recent update:2025-08-01

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Development and production of prototype/Small-scale production | Machining | General-purpose milling General-purpose lathe machining Deep hole drilling Thread-cutting Machining/Handles small-scale production (order from 1 piece) Iron Stainless steel Keyway milling Casting |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC milling NC lathe machining 5-face/5-axis machining Five-face machining Boring milling |

| Assembly/Inspection | Assembly | Industrial machinery assembly |