- Telephone number: +81-4-7145-2811

- FAX: +81-4-7145-6800

- Website

Chuobane Co., Ltd. specializes in precision springs under 3.0mm diameter. We offer expert consultation and manufacturing of custom springs using various materials for diverse industries.

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

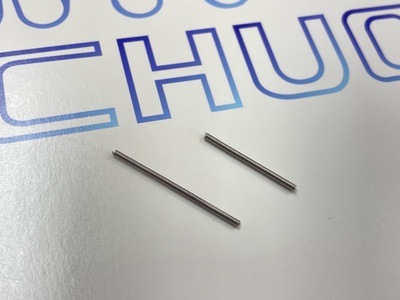

Diameter: less than 0.6 mm( Parts manufacturing / Spring ) |

|---|---|

|

|

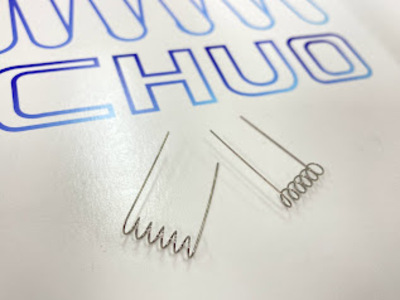

Formed wire spring( Parts manufacturing / Spring ) |

|

|

Shaped spring( Parts manufacturing / Spring ) |

|

|

Compression coil spring( Parts manufacturing / Spring ) |

|

|

Torsion spring( Parts manufacturing / Spring ) |

|

|

Battery spring( Parts manufacturing / Spring ) |

|

|

Double torsion spring( Parts manufacturing / Spring ) |

Icon

Company info

| Company name | Chuobane Co., Ltd. | Website URL | https://www.chuobane.co.jp/ |

|---|---|---|---|

| Street address |

Kashiwa-shi Chiba Japan

[See map] |

Person in charge | KasaharaMei |

| Telephone number | +81-4-7145-2811 | Fax number | +81-4-7145-6800 |

| Capital | 45,000,000 JPY | Employees | 22 |

| Annual sales | 300,000,000 JPY | EMIDAS Member Number | 53955 |

| Type of manufacturing | Furniture / Construction material / Medical equipment | ||

| Main 3 products |

|

||

PR message

【Company Profile】

●Specializing in precision springs with wire diameters of 3.0 mm or less.

●Offering comprehensive consultations on material selection, specifications, and design challenges for springs.

【Expertise】

●Proficient in processing special materials such as:

・Stainless steel and piano wire

・Platinum, titanium, tungsten, aluminum alloys, and resin-coated materials

●Skilled in manufacturing springs from non-circular wires, including square and rectangular wires.

●Recent achievements:

・Successfully processed 30 micron platinum torsion springs

・Manufactured 45 micron square compression coil springs

【Industries】

●Automotive

●Housing hardware

●Medical devices

●Writing instruments

●Various other fields

【Environmental Commitment】

●Strict management of environmentally hazardous substances.

●Compliant with Restriction of Hazardous Substances (RoHS) and End-of-Life Vehicle (ELV) directives.

●Continuously updating and conducting surveys on Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) Substances of Very High Concern (SVHC) as per customer requirements.

【In-house Capabilities】

●Equipped with Sodick AQ325L wire electrical discharge machine.

●Ability to produce:

・Press dies

・Forming machine dies

・Machine tools

・Inspection jigs

●Flexible production capabilities across various equipment types.

●Offering surface treatment, polishing, and assembly services for springs.

●Capable of delivering finished products.

●Handling both prototypes and mass production with meticulous attention to detail.

【Additional Information】

Video content available on our website and social media platforms.

Website: https://www.chuobane.co.jp/

【Contact】

Chuobane Co., Ltd.

1116-29,Takada,Kashiwa-shi,Chiba,Japan

Most recent update:2025-10-28

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Development and production of prototype/Small-scale production | Machining | Iron Stainless steel Aluminum alloy Titanium alloy Nickel alloy Titanium Brass |

| Die manufacturing | Spring mold | Designing Manufacturing |

| Mass production | Metal press | Forming Coining Iron Stainless steel Copper Brass Phosphor bronze Thickness Single press (below 80 t) Progressive press (35 - 80 t) |

| Assembly/Inspection | Assembly | Construction component assembly |

| Parts manufacturing | Electrical part | Coil manufacturing |

| Parts manufacturing | Spring | Terminal spring Compression coil spring Tensil coil spring Torsion spring Double torsion spring Leaf spring Shaped spring Battery spring Formed wire spring Torsion spring Carbon steel Piano wire (carbon wire) Stainless steel Copper alloy Diameter Diameter |