- Telephone number: +81-4-7145-2811

- FAX: +81-4-7145-6800

- Website

- Basic Info

- Equipment

- Technology & Products

- History, Philosophy & Quality

- Map / HQ

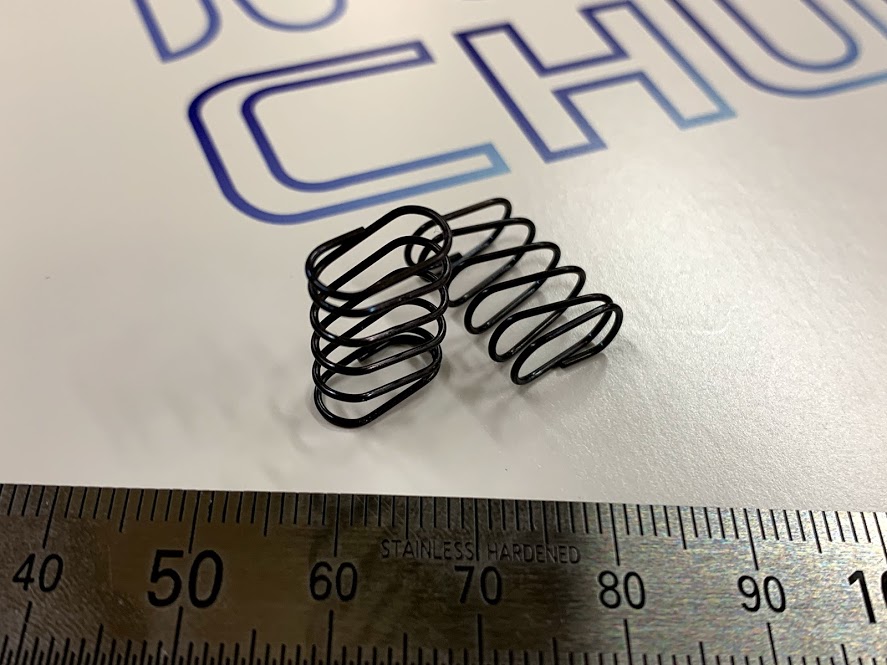

Oval Springs for Architectural and Automotive Applications

Industry

Automobile (mass production)

Furniture/Interior

Construction machinery parts

Specifications

- Materials:Stainless steel

Steel - Lots:1 - No upper limit

- Precision:Within general tolerance

Conventional technologies/differences from other companies

We specialize in manufacturing oval springs that are integral components in both architectural and automotive parts.

Unique Design for Space Constraints

When space limitations necessitate an oval shape, our springs, as shown in the image, provide the perfect solution. These specially designed springs excel in applications where standard circular springs may not fit.

Material Versatility

We offer a wide range of materials to suit various needs:

●Piano wire

●Stainless steel

●Steel wire

●Oil-tempered wire

●And more

The Tempering Process

In spring manufacturing, tempering (heat treatment) is a crucial step. This process significantly affects the spring's final shape and properties.

How Tempering Affects Different Materials

●SWP and SWC (Piano wire and Hard steel wire):

●Coil diameter decreases

●Free length increases

●SUS (Stainless steel wire):

●Coil diameter increases

●Free length decreases

Our Approach

We consider these material-specific changes throughout our manufacturing process. By carefully managing spring production and tempering, we ensure that the final product meets your exact specifications for shape and force.

Our expertise allows us to deliver springs that perform precisely as required in your applications, whether for architectural components or automotive parts.

【Additional Information】

Video content available on our website and social media platforms.

Website: https://www.chuobane.co.jp/

【Contact】

Chuobane Co., Ltd.

1116-29,Takada,Kashiwa-shi,Chiba,Japan

Company info

| Company name | Chuobane Co., Ltd. | EMIDAS Member Number | 53955 |

|---|---|---|---|

| Country | Japan | Street address |

Kashiwa-shi Chiba Japan |

| Telephone number | +81-4-7145-2811 | Fax number | +81-4-7145-6800 |

| Employees | 45,000,000 JPY | Annual sales | 300,000,000 JPY |

| Employees | 22 | Person in charge | KasaharaMei |

| Type of manufacturing | Furniture / Construction material / Medical equipment | ||