- Telephone number: +81-78-351-2531

- FAX: +81-78-361-1484

- Website

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

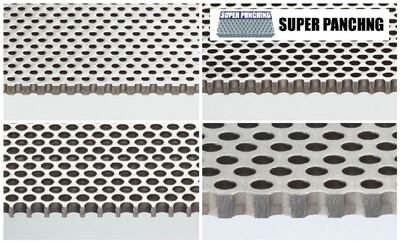

Perforated metal( Material / Steel component distribution ) |

|---|---|

|

|

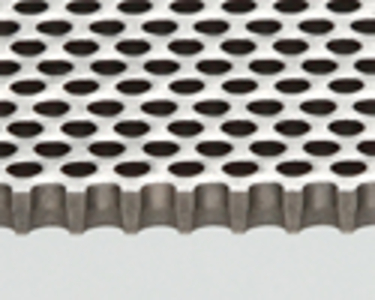

Expanded metal( Material / Steel component distribution ) |

|

|

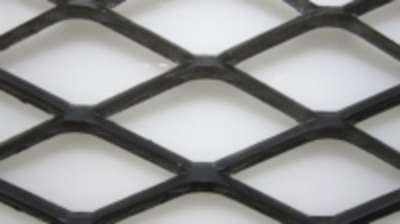

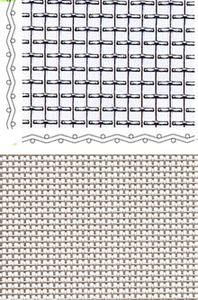

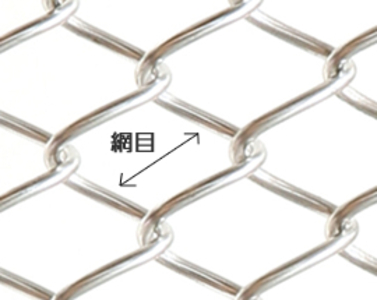

Metallic mesh manufacturing( Parts manufacturing / Other parts ) |

|

|

Filter manufacturing( Parts manufacturing / Other parts ) |

|

|

Construction and civil engineering material manufacturing( Product manufacturing / Construction and civil engineering machinery manufacturing ) |

|

|

Plant equipment manufacturing( Product manufacturing / Plant equipment manufacturing ) |

|

|

Turret punch press processing( Development and production of prototype/Small-scale production / Blank cutting ) |

|

|

Punching( Development and production of prototype/Small-scale production / Prototype processing ) |

|

|

Blanking( Mass production / Metal press ) |

|

|

Sheet metal protocol manufacturing( Development and production of prototype/Small-scale production / Sheet-metal processing ) |

Icon

Company info

| Company name | Okutani Wire Netting MFG Co., Ltd. | Website URL | |

|---|---|---|---|

| Street address |

Koube-shi Chuou-ku Hyogo Japan

[See map] |

Person in charge | Keigou Yoshikawa |

| Telephone number | +81-78-351-2531 | Fax number | +81-78-361-1484 |

| Capital | 10,000,000 JPY | Employees | 63 |

| Annual sales | 1,200,000,000 JPY | EMIDAS Member Number | 64376 |

| Type of manufacturing | Heavy electric machinery / Construction material / Transportation equipment | ||

| Main 3 products |

|

||

| Primary clients |

|

||

PR message

Since the company's foundation in 1895, we have been growing together with Kobe while being the leading company in the wire gauze industry. After the industrial evolution, we began focusing on innovating and researching for better quality. We have innovated a unique automatic high speed and high precision punching machine which can produce delicate and durable punched metals within short lead time. We also have achieved to introduce a new innovative technique called "super punching": shortening the distance between each hole to the point where it is less than the diameter of a hole. Currently, we are the best in the execution of the super punching technique. In addition, we have become the wire gaze supplier for a variety of industries: household product manufacturing, constructing, shipbuilding, electronic machinery manufacturing and semiconductor producing machinery manufacturing.

As a result of such a long company history we have a show room with over 1000 products of wire gazes and punching metals, as old as 140 years, displayed to entertain clients from all over the country. If you have the chance to visit OKUTANI WIRE NETTING, MFG, CO., LTD. please take a look at our show room and feel the OKUTANI quality.

Most recent update:2023-07-03

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Material | Steel component distribution | Pickled steel plate Heavy plate Stainless steel Shaped stainless steel Perforated metal Expanded metal Hot-rolled steel plate Cold-rolled steel plate Electroplated steel plate Chequered plate |

| Material | Specialized material distribution | Molybdenum alloy |

| Material | Nonferrous metal distribution | Plate Flat steel plate Steel bars and shapes Copper and brass products Titanium Nickel Others |

| Material | Plastic material distribution | PVC (polyvinyl chloride) PP (polypropylene) PA (nylon/polyamide) PC (polycarbonate) Fluororesin FRP (fiber reinforced plastic) |

| Development and production of prototype/Small-scale production | Sheet-metal processing | Can manufacturing NC set press Precision sheet metal machining Sheet metal protocol manufacturing Pipe bending Deburring Mirror surface machining Hair line machining 3-roll bending (2 m or longer) Bending (hydraulic) |

| Development and production of prototype/Small-scale production | Blank cutting | Turret punch press processing Shearing Cutting Laser processing (longer than 121.2 m) Shearing (longer than 121.2 m) CO2 laser machining |

| Development and production of prototype/Small-scale production | Welding/Adhesive bonding | Spot welding TIG welding (argon welding) Plasma welding Arc welding |

| Development and production of prototype/Small-scale production | Prototype processing | Punching Welding Bending Small-size prototype manufacturing |

| Mass production | Metal press | Bending Blanking Iron Stainless steel Aluminum Copper Brass Phosphor bronze Titanium Plated steel plate Nickel Thickness Thickness Thickness Single press (below 80 t) Progressive press (35 - 80 t) |

| Parts manufacturing | Other parts | Sign board manufacturing Filter manufacturing Metallic mesh manufacturing |

| Product manufacturing | Plant equipment manufacturing | Plant equipment manufacturing |

| Product manufacturing | Construction and civil engineering machinery manufacturing | Construction and civil engineering material manufacturing |

| Product manufacturing | Medical equipment manufacturing | Medical equipment manufacturing |

| Product manufacturing | Others | Transportation equipment manufacturing |