- Telephone number: +81-78-351-2531

- FAX: +81-78-361-1484

- Website

EMIDASBLOG

1-4 / 4 hits

Okutani Show Room received “Best KOBE Shop Design” award

Our Okutani show room received award by KOBE Shop design which purpose is to offer an opportunity for citizens to see and touch beautiful designed crafts.

Our show room opened in 2008 and was initiated by common’s desire to see the actual product image.

We have changed part of the first floor and, currently, we have over 1000 products to displayed.

There is over few hundred year’s worth of history in our show room.

Please visit our show room and feel the quality of Okutani!

Most recent update2012-10-10

Branding strategy to make our products appeal to the world

We have been extending our market shares to Europe and North America by attending international recognized exhibits, such as the Hannover Messe, with our super punching technology. In addition to those actions, we also have opened a website, "Punching world". It only contains information regarding punching metal and creates unique characters, such as the 'punching man', for 4 main products: wire nets, expand metal, wire mesh and demister. Besides, we have a show room in the head quarter’s first floor which also can be used as a business space.

Most recent update2012-10-10

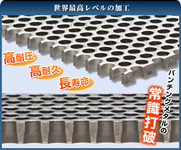

High precision and high durability punching metal

Punching metals, produced with a cutting-edge technique, are processed by the "high speed punching machine" which was developed by our company to use for ventilating air, ventilating sound, filtering, sound proofing and for high durability in greenhouses. In addition, we can punch press over 14 different materials and make over 1000 different shapes of metal molds. One example that easily rings a bell is ventilating air located below Shinkansen seats.

Most recent update2012-10-10

Made possible to do super punching!!

In the past, it was thought that creating a hole with a shorter diameter than the board thickness or pressing thin board was impossible.

However, we have achieved to make the impossible possible while lowering the cost of processing compared to the machining process or laser beam processing with 3mm thickness, hole diameter and 2mm in conventional punching press. As we can process from thin boards to thick boards with shorter than board thickness distances of each hole, products we manufacture are suitable for a wide variety of usages.

Most recent update2012-10-10

1-4 / 4 hits