- Telephone number: +81-25-777-2410

- FAX: +81-25-777-2881

- Website

Products, Expertise & Unique Technical Info

Manufacturing category info

|

|

Thin wall molding( Mass production / Plastic ) |

|---|---|

|

|

Thin wall injection molding die( Die manufacturing / Plastic mold ) |

|

|

Injection molding die( Designing / Mold designing ) |

|

|

Insert molding die( Die manufacturing / Plastic mold ) |

|

|

Small-size prototype manufacturing( Development and production of prototype/Small-scale production / Prototype processing ) |

|

|

Wire electric discharge machining( Development and production of prototype/Small-scale production / Electrical discharge machine ) |

|

|

Electric discharge machining( Development and production of prototype/Small-scale production / Electrical discharge machine ) |

|

|

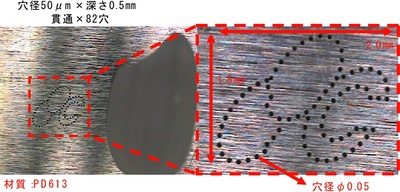

Micro hole machining( Development and production of prototype/Small-scale production / Electrical discharge machine ) |

|

|

LCP (liquid crystal polymer)( Mass production / Plastic ) |

|

|

Engineering plastic( Mass production / Plastic ) |

Icon

Company info

| Company name | hakkai inc. | Website URL | http://www.hakkai.co.jp/english2/ |

|---|---|---|---|

| Street address |

Minamiuonuma Niigata Japan

[See map] |

Person in charge | yoshiaki sato |

| Telephone number | +81-25-777-2410 | Fax number | +81-25-777-2881 |

| Capital | 57,300,000 JPY | Employees | 182 |

| Annual sales | 2,092,000,000 JPY | EMIDAS Member Number | 72463 |

| Type of manufacturing | Audio-video equipment / Electronic parts / Electrical component for transportation equipment | ||

| Main 3 products |

|

||

| Primary clients |

|

||

PR message

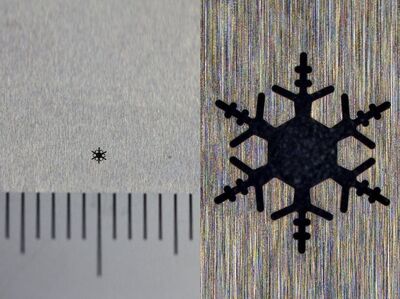

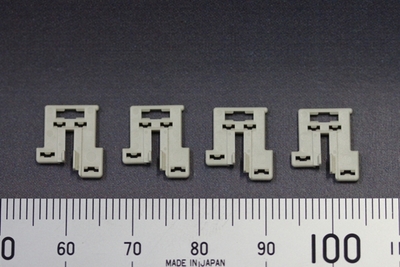

hakkai inc. offers expertise with ultra-fine precision plastic parts which are used in various products ranging from items that help you in your everyday life like home game consoles, Blu-ray and DVD players, PCs, digital cameras, video cameras, mobile phones, wristwatches, flatscreen TVs and automobiles, and to machine tools employed at factories.

Our mold-building techniques, being packed with our unique know-how, are what allows our company to perform fine, precision plastic molding. We perform speedy design and rolling analysis with 3D CAD tools and have numerous state-of-the-art machines, such as ultra-fine wire cutters for wire diameters of 20 microns, to answer tough customer demands with optimal mold construction.

At our molding factory, we have reached numerous achievements and gained experience mass-producing small precision parts weighing 20 tons or less with our 145 injection molding machines that run unmanned 24 hours a day. We are producing over 100 million units a month for roughly 600 product types. We engage in a wide range of business with clients from leading companies, whose brands are well-known nationwide, to companies that are prominent despite lacking name recognition.

Our superior technical prowess is also present in the development and manufacture of all types of automated machinery. For rotor assembly equipment, we can do insert molding of the world's smallest gears which are used in wristwatches.

We began accepting orders for prototypes and small lots as a new business in April 2009. We offer quick delivery of small products weighing 20 tons or less at low cost with our complete production system.

In 2008, hakkai was selected as one of the Ministry of Economy, Trade and Industry's "300 Energetic Small to Medium Manufacturers" and in 2009 we were selected as one of the "1,400 Job-Creating Firms - Leaders in Training and Investment into Human Resources”.

Most recent update:2025-11-27

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Injection molding die |

| Designing | Simulation | CAE fluid analysis |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining Micro hole machining Electric discharge machining |

| Development and production of prototype/Small-scale production | Grinding processing | Plane grinding Form grinding |

| Development and production of prototype/Small-scale production | Prototype processing | Small-size prototype manufacturing |

| Die manufacturing | Plastic mold | Designing Manufacturing Part processing Mold base machining 3D modeling Injection molding die Insert molding die Below 60 t Cassette-type molding die Thin wall injection molding die Injection molding die for microfabrication (5 mm or smaller) Core and cavity machining |

| Mass production | Plastic | Insert molding Engineering plastic PBT (polybutylene terephthalate) PPS (polyphenylene sulfide) LCP (liquid crystal polymer) Below 60 t Injection molding Thin wall molding |

![Gear for watch [Fine Plastic Molding] PA](/temp/400_300_ea42c503eae01ad77073516bc67270ecd5b9ae4b.jpg)

![Thread Form Processing SKH51 [precision mold processing] Test processing](/temp/400_300_f9219163e1900268b9523f1dce5c87126930fbe4.jpg)

![Automotive Control Relay CASE [molding in Clean Room]](/temp/400_300_be038b3b7f270bfdd785a7ae2de1b9ec307ebf17.jpg)

![Gear for watch [Fine Plastic Molding] PA](/temp/110_70_ea42c503eae01ad77073516bc67270ecd5b9ae4b.jpg)

![Thread Form Processing SKH51 [precision mold processing] Test processing](/temp/110_70_f9219163e1900268b9523f1dce5c87126930fbe4.jpg)

![Automotive Control Relay CASE [molding in Clean Room]](/temp/110_70_be038b3b7f270bfdd785a7ae2de1b9ec307ebf17.jpg)