- Telephone number: +81-593-64-7111

- FAX: +81-593-64-6410

- Website

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Progressive press (200 - 500 t)( Mass production / Metal press ) |

|---|---|

|

|

Progressive die designing (auto)( Designing / Mold designing ) |

|

|

Progressive die( Die manufacturing / Press die ) |

|

|

Progressive die designing (light electrical)( Designing / Mold designing ) |

|

|

Blanking die( Die manufacturing / Press die ) |

|

|

NC data creation (press)( Designing / Mold designing ) |

|

|

Progressive press (80 - 200 t)( Mass production / Metal press ) |

|

|

Progressive press (35 - 80 t)( Mass production / Metal press ) |

|

|

Die set machining( Die manufacturing / Press die ) |

|

|

General metal press die( Designing / Mold designing ) |

Icon

Company info

| Company name | Ito Seisakusho Co., Ltd. | Website URL | |

|---|---|---|---|

| Street address |

Yokkaichi Mie Japan

[See map] |

Person in charge | Kotake |

| Telephone number | +81-593-64-7111 | Fax number | +81-593-64-6410 |

| Capital | 50,000,000 JPY | Employees | 102 |

| Annual sales | 3,350,000,000 JPY | EMIDAS Member Number | 72592 |

| Type of manufacturing | Transportation equipment / Electronic parts / Office automation equipment | ||

| Main 3 products |

|

||

PR message

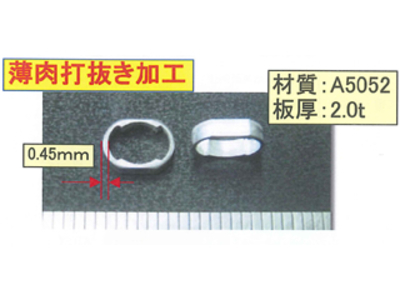

Since our company was established, we have developed our business as a pioneer in progressive mold design and manufacture and press parts processing for automobile parts. 95% of our products are automobile parts. We are currently rolling out about 800 different parts and deliver four truckloads of parts each day (including the area near Kariya, Aichi Prefecture). We are thorough in conserving our human resources in the factories, with scrap ejected by our presses being automatically collected by conveyors. We make steady quality and high productivity possible by press stamping highly accurate parts with complex shapes--which are traditionally produced through multiple processes--with cold forging progressive molds. We do this with the unique knowledge we have accumulated in mold structures, such as long-lasting tools, mold cooling, lubrication and rigidity.

Mold Design

We have adopted our company's own automated design system for progressive mold design. After the layout, we instantly draft assembly and part charts, then simultaneously show the processed data at 8 machining centers and 9 wire cutters. We demonstrate unparalleled results for quick delivery and cost reduction.

Press Stamping

We have 60 presses of up to 400 tons.

Capable of producing 130 custom die sets per month with our sister company, Eaton.

Our overseas base, ISPC (Ito Seisakusho Philippines Corporation, is growing so quickly that it can provide support back to HQ in Japan.

Most recent update:2024-02-07

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Progressive die designing (light electrical) Progressive die designing (auto) General metal press die NC data creation (press) |

| Development and production of prototype/Small-scale production | Machining | Iron Aluminum alloy |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) Machining (horizontal) |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining |

| Development and production of prototype/Small-scale production | Grinding processing | Plane grinding |

| Development and production of prototype/Small-scale production | Welding/Adhesive bonding | Spot welding |

| Die manufacturing | Press die | Designing Manufacturing Part processing Plate machining Die set machining Drawing die Bending die Blanking die Progressive die Below 60 t 60 - 300 t Over 300 t Compound die |

| Mass production | Metal press | Drawing Bending Blanking Forming Shaving Coining Iron Stainless steel Aluminum Copper Brass Phosphor bronze Plated steel plate Stainless steel material for spring Thickness Progressive press (35 - 80 t) Progressive press (80 - 200 t) Progressive press (200 - 500 t) |

| Surface treatment | Barrel polishing | Barrel finishing (vibration) Barrel finishing (rotation) |

| Surface treatment | Other surface treatment | Buffing |

| Assembly/Inspection | Assembly | Auto parts assembly |

| Assembly/Inspection | Inspection | Metal press |

| Parts manufacturing | Electrical part | Harness processing Connector manufacturing |

| Parts manufacturing | Spring | Thin leaf spring |