- Telephone number: +81-248-28-2126

- FAX: +81-248-28-2570

- Website

Products, Expertise & Unique Technical Info

Manufacturing category info

|

|

Five-face/axes machining( Mass production / Mechanical processing ) |

|---|---|

|

|

Machining( Mass production / Mechanical processing ) |

|

|

Complex turning machining( Mass production / Mechanical processing ) |

|

|

NC milling machining( Mass production / Mechanical processing ) |

|

|

NC turning machining( Mass production / Mechanical processing ) |

|

|

Aluminum alloy( Mass production / Mechanical processing ) |

|

|

Copper alloy( Mass production / Mechanical processing ) |

|

|

Stainless( Mass production / Mechanical processing ) |

|

|

Turning machining(plastic)( Mass production / Mechanical processing ) |

|

|

High precision( Mass production / Mechanical processing ) |

Icon

Company info

| Company name | Sacra-Tech Corp. | Website URL | http://www.sacra-tech.co.jp |

|---|---|---|---|

| Street address |

Sirakawa city Fukushima Japan

[See map] |

Person in charge | SACRA-TECH CO.,LTD. |

| Telephone number | +81-248-28-2126 | Fax number | +81-248-28-2570 |

| Capital | 35,000,000 JPY | Employees | 65 |

| Annual sales | 935,000,000 JPY | EMIDAS Member Number | 73752 |

| Type of manufacturing | Industrial machinery / Telecommunication equipment / Medical equipment | ||

| Main 3 products |

|

||

| Primary clients |

|

||

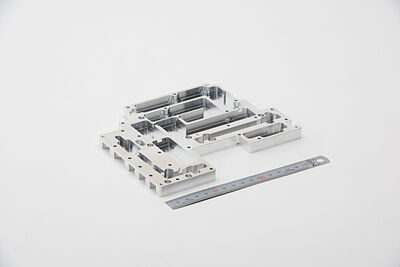

PR message

We are machining precision parts (5 axis and 3 axis simultaneity) specialists, utilizing 51 machines (MC and combined lathe). We manufacture a wide range and a wide variety of products from fields of medical, communication, defense and space, semiconductor related, and aluminum precision parts.

Our specialized type of manufacturing is complex shaped parts which require 5 axis processing. We have acquired ISO 9001 and ISO 14001 as a metal processing maker with the goal of “The Best Hitozukuri (prosperity of humanity) and Monozukuri (art of craftsmanship)”

Although the amount of estimate requests with complex details is on raise, we, Sacra Tech Co., endeavor to respond back as quickly as possible within 24 hours.

To manage to respond at such rate, it is essential to obtain abundant knowledge and experience. We are promoting information sharing within the company to support each worker’s growth. In addition, we, Sacra Tech Co., have begun continuous manufacturing from designing jigs to assembling products.

For example:

・I have an idea but don’t have the drawing.

・We are lacking on engineering designers.

・There is limited time left till lead time.

・Can Sacra Tech Co., start a project from drawing phase at the processing site?

・・・etc

If you have similar questions as described above, please feel free to contact us.

Most recent update:2024-04-19

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Development and production of prototype/Small-scale production | Machining | Tapping Deep hole drilling Rolling Thread-cutting Profile milling Straightening Machining/Handles small-scale production (order from 1 piece) Stainless steel Aluminum alloy Copper alloy Titanium alloy Machining (resin) Shaper machining Simultaneous 5-axis machining Milling (resin) Lathe machining (resin) Handles microfabrication Honing Titanium Brass |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC milling NC lathe machining 5-face/5-axis machining Five-face machining Boring milling NC vertical lathe Combined lathe machining Machining (horizontal) Handles 2.5-dimensional processing Handles 3D processing |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining |

| Development and production of prototype/Small-scale production | Prototype processing | Plastic protocol machining Small-size prototype manufacturing Chassis prototype manufacturing Porous plastic prototype |

| Mass production | Mechanical processing | Machining NC milling machining NC turning machining Tapping machining Five-face/axes machining Complex turning machining Wire machining Rolling machining Screw cutting machining Micro-hole machining Electrical discharge machining Stainless Aluminum alloy Copper alloy Titanium alloy Turning machining(plastic) Honing machining Titanium Fine particle material accepted Ultra-thin High precision |

| Parts manufacturing | Machinery part | Valve manufacturing Vacuum components manufacturing Pressure container manufacturing Connection parts manufacturing Optical parts manufacturing Measurement devices manufacturing Ring Mechanical parts |