- Telephone number: Log in to display

- FAX: Log in to display

- Website

Products, Expertise & Unique Technical Info

|

|

Manufacturing category info

|

|

Gear designing( Designing / Product and part designing ) |

|---|---|

|

|

Gear manufacturing( Parts manufacturing / Machinery part ) |

|

|

Injection molding ( Mass production / Plastic ) |

|

|

Gear hobber( Development and production of prototype/Small-scale production / Machining ) |

|

|

NC turning machining( Mass production / Mechanical processing ) |

|

|

Broaching machining( Mass production / Mechanical processing ) |

|

|

Sintered metal( Mass production / Mechanical processing ) |

Icon

Company info

| Company name | Matex Co., Ltd. | Website URL | https://www.matex-japan.com/e/ |

|---|---|---|---|

| Street address |

Yao-city Osaka Japan

[See map] |

Person in charge | Shoichiro Yagi |

| Telephone number | Log in to display | Fax number | Log in to display |

| Capital | 8,880,000 JPY | Employees | 60 |

| Annual sales | 1,750,000,000 JPY | EMIDAS Member Number | 73819 |

| Type of manufacturing | Industrial machinery / Electronic parts | ||

| Main 3 products |

|

||

PR message

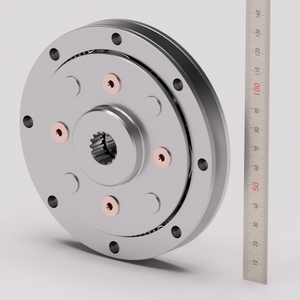

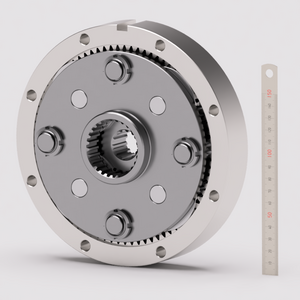

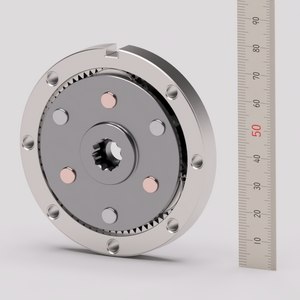

Matex is a professional company of designing and manufacturing planetary gears, gearboxes, and transmissions. We have many achievements in development and manufacturing according to customer's specifications including home appliances, machinery, automobile parts, and health equipment. In addition, we can fully respond to your requirements, including contracted development and manufacturing of mechanical parts such as actuators, power units, pumps, and plastic injection molding and assembly.

Company Website:

https://www.matex-japan.com/e/

YouTube:

https://www.youtube.com/channel/UCrl0VRD7MBNjaBNTRVov4XQ

Through a long history, we have several important users.

・Aisin AW Co., Ltd.

・Hitachi Astemo, Ltd.

・IHI AEROSPACE Co., Ltd.

・Mitsubishi Heavy Industries, Ltd.

・Panasonic Corporation.

・ShinMaywa Industries,Ltd.

・TOTO Ltd.

・TOSHIBA Corporation

・Toyota Motor Corporation

・Yamaha Motor Co., Ltd.

and so on

Most recent update:2025-08-22

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Injection molding die 3D modeling (plastic) |

| Designing | Product and part designing | Gear designing |

| Designing | Jig and tool designing | General jig designing Mass production jig designing |

| Designing | Electrical planning | Electrical machinery and apparatus designing |

| Designing | Simulation | 3D modeling CAE fluid analysis Cutting Resin |

| Development and production of prototype/Small-scale production | Machining | General-purpose lathe machining Gear hobber Rolling Broaching |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC milling NC lathe machining Combined lathe machining |

| Development and production of prototype/Small-scale production | Casting | die-cast Metal injection molding (MIM) |

| Die manufacturing | Plastic mold | Designing Manufacturing Part processing Injection molding die Insert molding die Outsert molding die Below 60 t 60 - 300 t 000 t 000 t and over |

| Die manufacturing | Rubber mold | 3D modeling Packing-related products |

| Die manufacturing | Powder metallurgy mold | Manufacturing Powder metallurgy mold part manufacturing Metal die |

| Mass production | Mechanical processing | Machining NC turning machining Complex turning machining Gear cutting machining Iron Sintered metal Broaching machining High precision |

| Mass production | Plastic | Insert molding Outsert molding General-purpose material PMMA (polymethyl methacrylate) Engineering plastic PBT (polybutylene terephthalate) PPS (polyphenylene sulfide) PI (polyimide) PEEK (polyetheretherketone) LCP (liquid crystal polymer) FRP (fiber reinforced plastic) Below 60 t 60 - 300 t 000 t Injection molding 000 t Metal injection molding (MIM) |

| Mass production | Rubber | NBR Packing-related products |

| Mass production | Powder metallurgy | Metal Below 500 g 500 g - 5 kg |

| Mass production | Die-casting | Aluminum |

| Mass production | Forging | Cold forging |

| Mass production | Casting | Metal injection molding (MIM) |

| Mass production | Grinding processing | Plane grinding |

| Surface treatment | Plating/Chemical conversion treatment | Black oxide finish |

| Surface treatment | Heat treatment | Quenching High frequency quenching Carburized quenching Nitridation Gas nitrocarburizing |

| Assembly/Inspection | Assembly | Precision equipment assembly Office equipment assembly Auto parts assembly Construction component assembly Industrial machinery assembly Toy and sundries assembly |

| Assembly/Inspection | Inspection | Plastic Forging Powder metallurgy |

| Assembly/Inspection | Side job processing | Manual labor |

| Parts manufacturing | Machinery part | Gear manufacturing Crank shaft manufacturing Shaft and roller manufacturing Mechanical parts |

| Parts manufacturing | Electrical part | Connector manufacturing Other electrical part manufacturing |

| Parts manufacturing | Electric board and electronic part | Electronic parts assembly and wiring |

| Auto parts manufacturing | Interior part | Seat parts |

| Product manufacturing | Household commodity | Office equipment manufacturing |

| Product manufacturing | Others | Transportation equipment manufacturing |