- Telephone number: Log in to display

- FAX: Log in to display

- Website

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Handles microfabrication( Development and production of prototype/Small-scale production / Machining ) |

|---|---|

|

|

Injection molding die( Designing / Mold designing ) |

|

|

Electric discharge machining( Development and production of prototype/Small-scale production / Electrical discharge machine ) |

|

|

Designing( Die manufacturing / Plastic mold ) |

|

|

Wire electric discharge machining( Development and production of prototype/Small-scale production / Electrical discharge machine ) |

|

|

Engineering plastic( Mass production / Plastic ) |

|

|

PEEK (polyetheretherketone)( Mass production / Plastic ) |

Icon

Company info

| Company name | Sayama Mold Manufacturing Co., Ltd. | Website URL | http://www.sayama-kanagata.co.jp/ |

|---|---|---|---|

| Street address |

Iruma Saitama Japan

[See map] |

Person in charge | Masayuki TSUZUKI |

| Telephone number | Log in to display | Fax number | Log in to display |

| Capital | 10,000,000 JPY | Employees | 30 |

| Annual sales | Unregister | EMIDAS Member Number | 74893 |

| Type of manufacturing | Electronic parts / Electrical component for transportation equipment / Medical equipment | ||

| Main 3 products |

|

||

PR message

Nestled within the lush landscapes of Iruma City, Saitama Prefecture, Sayama Mold Seisakusho stands as a beacon of ultra-precision processing. We are a boutique factory where the art of mold-making is not just a profession but a passion. Our journey from design to the creation of molded products and manufacturing through our specialized molds is driven by one goal: to deliver products that exceed our customers' expectations. Embracing the challenge of advancing technology, we are committed to innovation and excellence in every mold we craft.

Your Solution for Fine Molds and Molding Challenges - Sayama Mold

Equipped with the finest machinery from renowned manufacturers like Yasuda Kogyo, Makino Milling Machine, and Mitsubishi Electric, Sayama Mold embodies precision. Our engineers, through rigorous training and dedication, maximize these technological marvels to offer superior processing capabilities. This fusion of talent and technology ensures the delivery of high-precision molded products to our valued customers. Extending our reach, our Singapore subsidiary enables us to cater to diverse needs globally, including VA/VE proposals, with unparalleled agility.

Uncompromised Quality Management

Our pursuit of micro-precision machining is supported by our serene location, free from urban vibrations, and a climate-controlled processing room set at 24±1℃. With ISO9001 and 14001 certifications, our commitment to quality manufacturing not only aims to satisfy our customers but also to honor the environment.

Most recent update:2025-12-21

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Injection molding die |

| Development and production of prototype/Small-scale production | Machining | Handles microfabrication |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining Electric discharge machining |

| Die manufacturing | Plastic mold | Designing Manufacturing Injection molding die Below 60 t 60 - 300 t |

| Mass production | Plastic | General-purpose material PMMA (polymethyl methacrylate) Engineering plastic PBT (polybutylene terephthalate) PPS (polyphenylene sulfide) PI (polyimide) PEEK (polyetheretherketone) LCP (liquid crystal polymer) Below 60 t 60 - 300 t Injection molding PES (polyethersulfone) |

| Product manufacturing | Medical equipment manufacturing | Medical equipment manufacturing |

| Product manufacturing | Household commodity | Bath products manufacturing |

| Product manufacturing | Watch/Glasses/Accessory/Jewelry | Watch assembly/manufacturing |

| Product manufacturing | Others | Transportation equipment manufacturing Telecommunication equipment manufacturing |

![[Micro / resin molding] Microchannel / used for blood test](/temp/400_300_282aacfa2e375edd6ffb29a1e8911158.jpg)

![Ultra-precision micro dies/molds / MIM (Metal Injection Molding) [Micro nozzle]](/temp/400_300_d0deb61ae02b216bd72cd81ad35f603f.jpg)

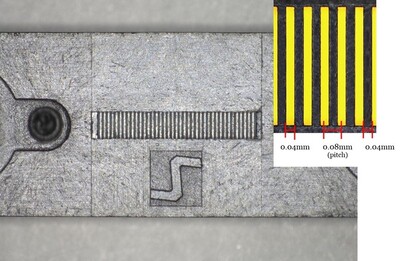

![Ultra-precision micro dies/molds / Molding [0.08mm micro connectors]](/temp/400_300_abefef2b1dce2b8a751e9bce417556a4.jpg)

![Ultra-precision micro dies/molds / Molding [0.025mm module micro gear]](/temp/400_300_150440d35ae4f25e700167f9f3a325a0.jpg)

![[Micro / resin molding] Microchannel / used for blood test](/temp/110_70_282aacfa2e375edd6ffb29a1e8911158.jpg)

![Ultra-precision micro dies/molds / MIM (Metal Injection Molding) [Micro nozzle]](/temp/110_70_d0deb61ae02b216bd72cd81ad35f603f.jpg)

![Ultra-precision micro dies/molds / Molding [0.08mm micro connectors]](/temp/110_70_abefef2b1dce2b8a751e9bce417556a4.jpg)

![Ultra-precision micro dies/molds / Molding [0.025mm module micro gear]](/temp/110_70_150440d35ae4f25e700167f9f3a325a0.jpg)