- Telephone number: +81-44-740-6800

- FAX: +81-44-740-6801

- Website

- Basic Info

- Equipment

- Technology & Products

- History, Philosophy & Quality

- Map / HQ

Nanogrind Technology|Sub-Micron Accuracy in Micro Component Manufacturing

Industry

---

Specifications

- Materials: ---

- Lots: ---

- Precision: ---

Conventional technologies/differences from other companies

【Limitations of Conventional Grinding】

Conventional grinding technologies cannot achieve the sub-micron precision required by today’s medical, semiconductor, and precision engineering industries. Standard processes often face issues such as deformation, poor surface finishes, and limited ability to handle ultra-hard materials. As components continue to shrink in size, these limitations make conventional methods insufficient.

【Sanwa Creation’s Nanogrind Advantage】

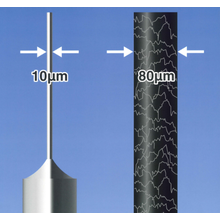

Sanwa Creation developed its proprietary Nanogrind technology to overcome these challenges. By using diamond grinding wheels and diamond powder, the company achieves nanometer-level precision that exceeds conventional grinding. This unique method ensures stable accuracy, smooth surfaces, and flexibility in design.

Key specifications include:

・Outer diameter tolerance: ±0.1 μm

・Roundness: 0.06 μm

・Surface roughness: Ra 0.0239 μm

・Diameters as small as 0.01 mm

・Workpiece lengths up to 2,000 mm

【Technical Advantages of Nanogrind】

Nanogrind offers capabilities that conventional technologies cannot provide:

・Sub-micron accuracy for advanced applications

・Smooth finishes that reduce friction and wear

・Production of stepped or tapered pins

・Processing of ultra-long shafts without distortion

・Compatibility with tungsten carbide, ceramics, diamond, and titanium

【Applications in the Medical Industry】

Nanogrind supports highly reliable medical components, including:

・Manipulator pins with tips under 1 μm

・Catheter components made from nickel-titanium alloys

・Dialysis plungers with nanometer-level surface roughness

・DNA micro-injection needles requiring extreme sharpness

【Applications in the Semiconductor Industry】

Semiconductor production requires flawless accuracy. Nanogrind enables:

・Micron pins for fuel injection and electronics

・LED production nozzles

・Micro-shafts for semiconductor processing tools

・High-precision components with stable sub-micron performance

【Integration with Centerless Grinding】

Unlike competitors, Sanwa Creation combines centerless grinding efficiency with Nanogrind accuracy. This approach allows mass production without compromising precision, offering both scalability and reliability.

【Quality Assurance】

Nanogrind is supported by strict quality management:

・ISO9001 certification

・RoHS compliance

・Inspection reports with every order

・Calibration certificates and traceability upon request

・3D metrology, roundness testers, and laser microscopes

【Conclusion】

Conventional grinding technologies cannot meet the demands of modern industries. Sanwa Creation’s Nanogrind technology delivers sub-micron accuracy, superior surface quality, and reliability across advanced materials. This innovation enables customers in medical, semiconductor, and precision engineering sectors to achieve new levels of performance and competitiveness.

【Contact Information】

Sanwa Creation Inc.

1-26-8 Miyauchi, Nakahara-ku, Kawasaki-shi, Kanagawa 211-0051, Japan

TEL: +81-44-740-6800

FAX: +81-44-740-6801

Website: https://www.sanwa-creation.co.jp/english/

Company info

| Company name | SANWA CREATION Co.,Ltd. | EMIDAS Member Number | 75462 |

|---|---|---|---|

| Country | Japan | Street address |

Nakahara Ward, Kawasaki Kanagawa Japan |

| Telephone number | +81-44-740-6800 | Fax number | +81-44-740-6801 |

| Employees | 10,000,000 JPY | Annual sales | |

| Employees | 38 | Person in charge | Takiguchi Jun |

| Type of manufacturing | Telecommunication equipment / Electronic parts / Electrical component for transportation equipment | ||