Products, Expertise & Unique Technical Info

Manufacturing category info

|

|

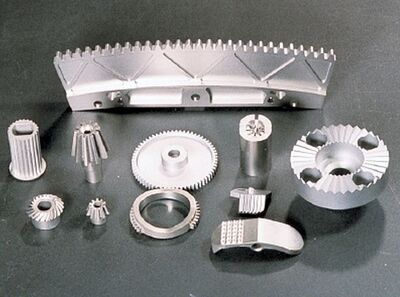

Lost-wax ( Mass production / Casting ) |

|---|---|

|

|

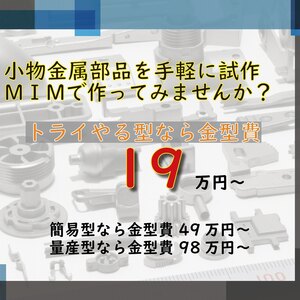

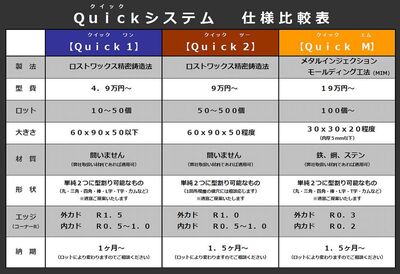

Metal injection molding (MIM)( Mass production / Casting ) |

|

|

Handles small-scale production( Mass production / Plastic ) |

|

|

Powder metallurgy mold part manufacturing( Die manufacturing / Powder metallurgy mold ) |

|

|

Aluminum alloy( Mass production / Casting ) |

|

|

Cast-iron ( Mass production / Casting ) |

|

|

Stainless steel( Development and production of prototype/Small-scale production / Machining ) |

|

|

Casting( Development and production of prototype/Small-scale production / Machining ) |

|

|

Casting( Assembly/Inspection / Inspection ) |

|

|

Copper alloy( Development and production of prototype/Small-scale production / Machining ) |

Icon

Company info

| Company name | Castem | Website URL | |

|---|---|---|---|

| Street address |

Fukuyama City Hiroshima Japan

[See map] |

Person in charge | Kazumasa Matsuo |

| Telephone number | +81-84-955-2221 | Fax number | +81-84-955-2065 |

| Capital | 79,960,000 JPY | Employees | 300 |

| Annual sales | 8,466,000,000 JPY | EMIDAS Member Number | 77539 |

| Type of manufacturing | Machine tools / Industrial machinery / Medical equipment | ||

| Main 3 products |

|

||

PR message

CASTEM Group has grown to a global company operating in Japan and Southeast Asian countries with the core business of precision casting.

Now we are at a turning point but we always have one faith,

"Be the best partner for our clients."

In the intensifying competition over the rising demand for high quality, low cost, timely delivery, varied product assortment, and small lots, we strive to provide customers with the best possible value.

Most recent update:2026-01-09

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Casting die designing |

| Designing | Product and part designing | Gear designing Measurement/testing device designing |

| Designing | Jig and tool designing | General jig designing Mass production jig designing |

| Development and production of prototype/Small-scale production | Machining | General-purpose lathe machining Tapping Deep hole drilling Thread-cutting Iron Stainless steel Aluminum alloy Copper alloy Molybdenum alloy Sintered metal Casting |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC milling NC lathe machining NC vertical lathe Machining (horizontal) |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining Electric discharge machining |

| Development and production of prototype/Small-scale production | Grinding processing | NC cylindrical grinding Plane grinding Cylindrical grinding |

| Development and production of prototype/Small-scale production | Jig manufacturing | General jig manufacturing Mass production jig manufacturing |

| Die manufacturing | Powder metallurgy mold | Manufacturing Powder metallurgy mold part manufacturing Metal die |

| Die manufacturing | Casting die | Designing Manufacturing 3D modeling Lost-wax casting die |

| Mass production | Plastic | Insert molding Below 60 t 60 - 300 t Injection molding Handles small-scale production Thin wall molding Metal injection molding (MIM) |

| Mass production | Powder metallurgy | Metal High rigidity Below 500 g |

| Mass production | Casting | Lost-wax Gravity casting Cast-iron Cast steel Aluminum alloy Copper alloy 500 g and below Over 500 g and less than 5 kg Metal injection molding (MIM) |

| Surface treatment | Polishing/Lapping | Buffing |

| Surface treatment | Heat treatment | Normalizing Annealing Straightening annealing |

| Surface treatment | Barrel polishing | Barrel finishing (rotation) |

| Surface treatment | Other surface treatment | Buffing Shot blast Sound blast Glass beads blast |

| Assembly/Inspection | Assembly | Office equipment assembly Industrial machinery assembly |

| Assembly/Inspection | Inspection | Casting |

| Parts manufacturing | Machinery part | Gear manufacturing Valve manufacturing Connection parts manufacturing Optical parts manufacturing |

| Parts manufacturing | Other parts | Lock manufacturing |