- Basic Info

- Equipment

- Technology & Products

- Movie

- History, Philosophy & Quality

- EMIDASBLOG

- Map / HQ

Cost-Effective Repeat Production by Leveraging Tooling

Industry

Automobile (mass production)

Manufacturing facilities

Food industry machinery

Specifications

- Materials:Aluminum

Stainless steel

Copper - Lots:100 - 1,000 lots

- Precision:0.1 mm - 1/100 mm

Conventional technologies/differences from other companies

Have you ever wished there were a more efficient way to repeatedly mass-produce metal components?

Lost wax casting is a proven casting method that enables stable, repeatable production of identical parts by making effective use of tooling.

Building on core technologies originating in the United States, our company has developed proprietary expertise in lost wax casting and now holds a leading share of the domestic precision casting market for general industrial applications.

We provide integrated manufacturing capabilities from tooling fabrication and near-net-shape casting to machining, complemented by surface treatment, heat treatment, and assembly through trusted partners.

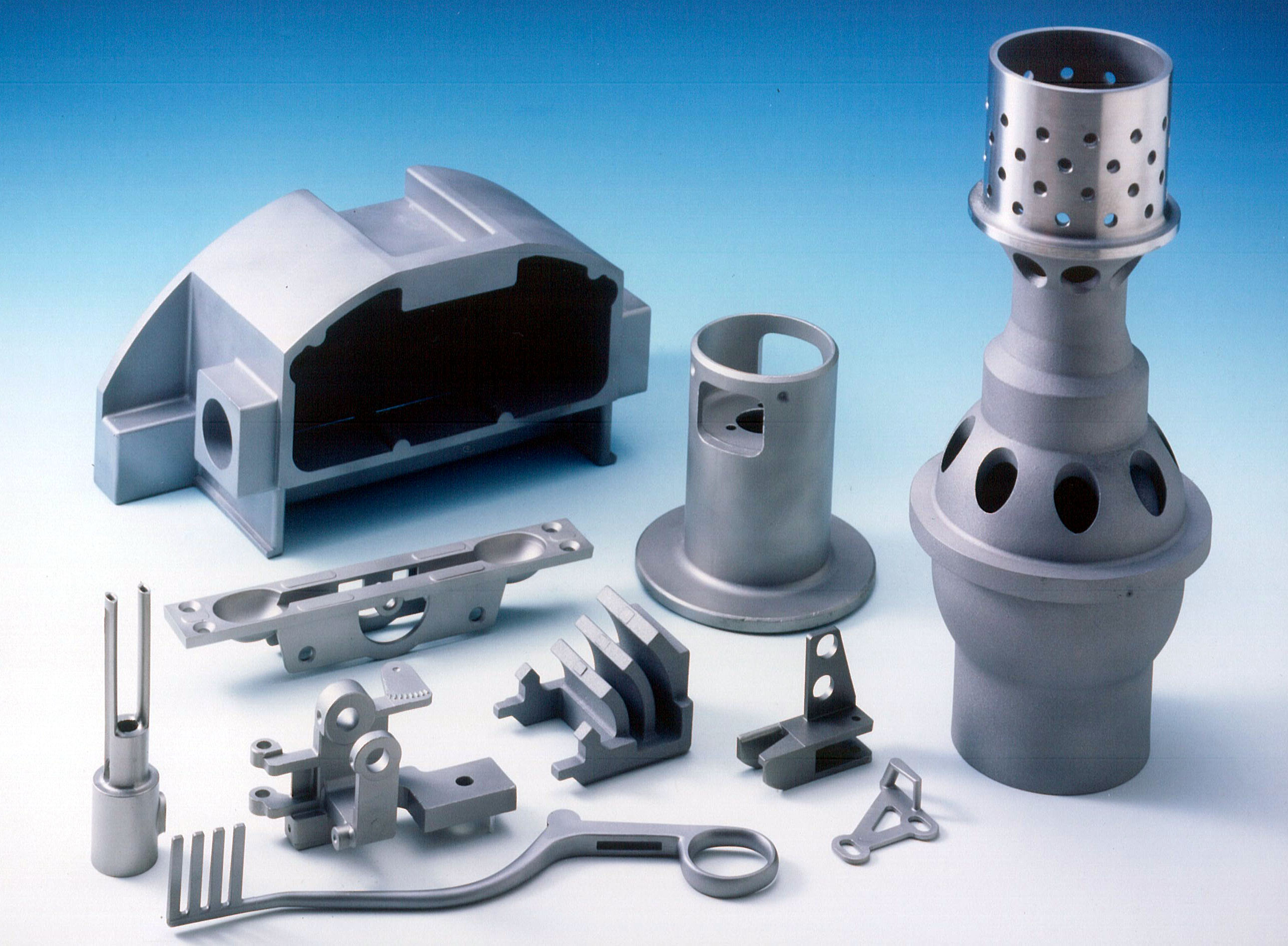

【What Is Lost Wax Precision Casting?】

Lost wax casting is a manufacturing process in which a wax pattern is injected into a mold, coated with ceramic to form a shell mold, and then cast to produce metal components. This method enables the production of highly precise parts with complex geometries.

【Key Advantages of Lost Wax Casting】

✅Well suited for hollow structures and complex three-dimensional geometries

✅Cost-effective aluminum tooling that can be used repeatedly over long production cycles

✅ A wide selection of more than 70 material grades

– Including steel, stainless steel, copper, aluminum, and special materials such as super-duralumin aluminum alloys

【Feel free to contact us about any manufacturing challenges!】

• “We want to integrate multiple parts into a single component.”

• “We need to improve strength.”

• “We want to reduce costs compared to machining.”

• “Welding and multiple secondary processes are increasing cost and lead time.”

We propose optimal manufacturing solutions tailored to your specific challenges and requirements.

In addition to lost wax casting, we can also recommend alternative processes such as Metal Injection Molding (MIM) or mold-less casting methods, depending on part size, application, and production volume.

For any metal component needs, please feel free to contact us.

Company info

| Company name | Castem | EMIDAS Member Number | 77539 |

|---|---|---|---|

| Country | Japan | Street address |

Fukuyama City Hiroshima Japan |

| Telephone number | +81-84-955-2221 | Fax number | +81-84-955-2065 |

| Employees | 79,960,000 JPY | Annual sales | 8,466,000,000 JPY |

| Employees | 300 | Person in charge | Kazumasa Matsuo |

| Type of manufacturing | Machine tools / Industrial machinery / Medical equipment | ||