- Basic Info

- Equipment

- Technology & Products

- Map / HQ

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Handles microfabrication( Development and production of prototype/Small-scale production / Machining ) |

|---|---|

|

|

Part processing( Die manufacturing / Plastic mold ) |

|

|

Machining (vertical)( Development and production of prototype/Small-scale production / NC machining ) |

|

|

Injection molding die( Die manufacturing / Plastic mold ) |

|

|

Insert molding die( Die manufacturing / Plastic mold ) |

|

|

Electric discharge machining( Development and production of prototype/Small-scale production / Electrical discharge machine ) |

|

|

Wire electric discharge machining( Development and production of prototype/Small-scale production / Electrical discharge machine ) |

|

|

Plane grinding( Development and production of prototype/Small-scale production / Grinding processing ) |

|

|

NC data creation( Die manufacturing / Plastic mold ) |

|

|

3D modeling (plastic)( Designing / Mold designing ) |

Icon

Company info

| Company name | Yoneyama Mold.Co.,Ltd | Website URL | |

|---|---|---|---|

| Street address |

Shimoina-gun Nagano Japan

[See map] |

Person in charge | hirata |

| Telephone number | +81-265-36-5476 | Fax number | +81-265-36-6309 |

| Capital | 10,000,000 JPY | Employees | 29 |

| Annual sales | 390,000,000 JPY | EMIDAS Member Number | 79478 |

| Type of manufacturing | Home electrical appliances / Electrical component for transportation equipment / Medical equipment | ||

| Main 3 products |

|

||

PR message

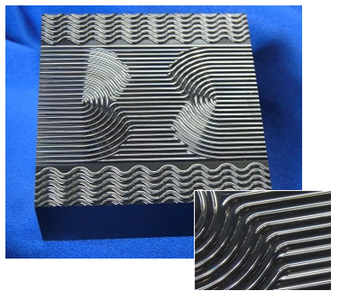

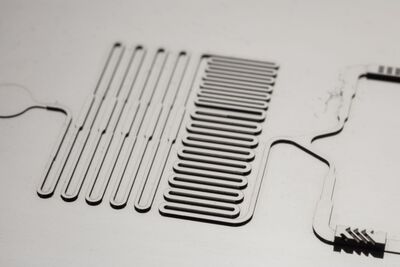

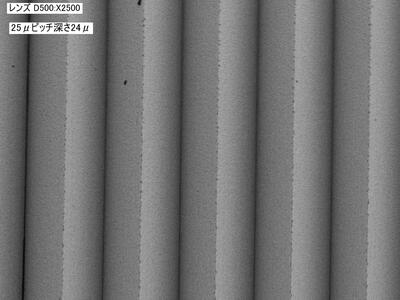

We are constantly pursuing the latest technology and constantly evolving in order to provide plastic molds that are trusted by our customers. In particular, in the field of microfabrication, we have 4 kitchens of ultra-high precision microfabrication machine "Roku-Roku Sangyo Android" with 50,000 rotation specifications, machining accuracy ± 1 μm.We have also realized a world of 2 μm by die-sinking electric discharge machine "Sodick AP3L". After the processing is completed, the accuracy is surely checked by the CNC 3D image measuring device "OGP Zip450" and the quality assurance system is established.

In addition, we can respond to ultra-short delivery times with our abundant facilities! We have some achievements such as complete set of mold, pre-hardened steel mold → 7 days, quenching mold →10 days production! We also welcome only mold parts processing or rent processing!

We pursue dreams through "manufacturing(=Monozukuri)" and create emotion and happiness.

Most recent update:2025-11-10

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Injection molding die 3D modeling (plastic) NC data creation (plastic) |

| Development and production of prototype/Small-scale production | Machining | General-purpose milling Machining/Handles small-scale production (order from 1 piece) Iron Stainless steel Aluminum alloy Copper alloy Machining (resin) Milling (resin) Handles microfabrication |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC milling Boring milling Machining (horizontal) Handles 2.5-dimensional processing Handles 3D processing |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining Micro hole machining Electric discharge machining |

| Development and production of prototype/Small-scale production | Grinding processing | Plane grinding Form grinding |

| Die manufacturing | Plastic mold | Designing Manufacturing Part processing Plate machining Mold base machining NC data creation 3D modeling Injection molding die Insert molding die Outsert molding die Below 60 t 60 - 300 t Electrode manufacturing Cassette-type molding die Injection molding die for microfabrication (5 mm or smaller) |

| Assembly/Inspection | Repair | Die repair |

Yoneyama Mold.Co.,Ltd

Yoneyama Mold.Co.,Ltd