Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

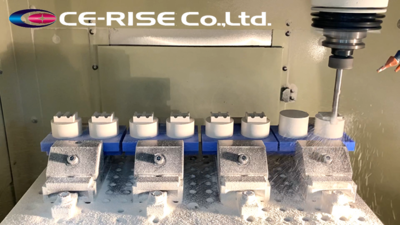

Machining( Mass production / Mechanical processing ) |

|---|---|

|

|

Plane grinding( Mass production / Grinding processing ) |

|

|

Cylindrical grinding( Mass production / Grinding processing ) |

|

|

Handles 3D processing( Development and production of prototype/Small-scale production / NC machining ) |

|

|

Metal die( Die manufacturing / Powder metallurgy mold ) |

|

|

NC turning machining( Mass production / Mechanical processing ) |

|

|

Shot blast( Surface treatment / Other surface treatment ) |

|

|

NC milling machining( Mass production / Mechanical processing ) |

|

|

Jig and tool manufacturing( Development and production of prototype/Small-scale production / Jig manufacturing ) |

|

|

Ceramic( Development and production of prototype/Small-scale production / Machining ) |

Icon

Company info

| Company name | CE-RISE Co.,Ltd.™(Ceramics Industries) | Website URL | |

|---|---|---|---|

| Street address |

Ota Tokyo Japan

[See map] |

Person in charge | Kazuyoshi Kitajima |

| Telephone number | +81-3-3755-0660 | Fax number | +81-3-3755-0708 |

| Capital | 50,000,000 JPY | Employees | 54 |

| Annual sales | Unregister | EMIDAS Member Number | 80084 |

| Type of manufacturing | Machine tools / Medical equipment / Lighting equipment | ||

| Main 3 products |

|

||

PR message

◆◆◆CE-RISE for prototyping, processing and manufacturing of ceramics products.

・Quick delivery, no mold, from 1 piece

・Quick turnaround time, no molds, from 1 piece to 2 pieces, 3 hours from drawing to quotation

・Delivery of ceramic products in as little as 5 days.

・From small quantity to mass production.

Highly functional ceramics (excellent mechanical, electrical, electronic, optical, chemical and biochemical properties) are useful for manufacturing products that require hardness, heat resistance, corrosion resistance, electrical insulation and other properties.

What are ceramics?

Ceramics are good for hard, heat-resistant, corrosion-resistant, and electrically insulating.

Typical examples include ceramics, refractories, glass, cement, and fine ceramics.

Fine ceramics, in particular, have superior mechanical, electrical, electronic, optical, chemical, and biochemical properties and advanced functions.

Ceramics can be broadly divided into Old Ceramics, such as ceramics, and Fine Ceramics, the differences of which are mainly due to the raw materials and their manufacturing methods.

Old ceramics are made from natural minerals such as potter's stone, feldspar, and clay, which are mixed, molded, and fired.

Fine ceramics are made from highly purified natural raw materials, artificial raw materials synthesized by chemical processes, or compounds that do not exist in nature.

By blending these raw materials, it is possible to obtain substances with the desired properties.

The blended raw materials undergo a complex and precisely controlled process of molding, firing, grinding, etc., to produce a material with high dimensional accuracy and high functionality.

The result is a high value-added product with advanced dimensional accuracy and high functionality.

Our Commitment to Seraize

Seraize has been manufacturing Fine Ceramics for half a century.

We are committed to the production of fine ceramics for half a century, and we are able to handle everything from raw materials to firing and post-processing in house.

By doing all of the ceramics manufacturing in-house, we are able to build the optimum conditions for each product and produce even better products.

better products. This is our company's commitment.

Translated with www.DeepL.com/Translator (free version)

Most recent update:2025-05-26

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Material | Specialized material distribution | Ceramic material |

| Development and production of prototype/Small-scale production | Machining | Ceramic |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC milling NC lathe machining Handles 3D processing |

| Development and production of prototype/Small-scale production | Jig manufacturing | Jig and tool manufacturing |

| Die manufacturing | Powder metallurgy mold | Manufacturing Metal die |

| Mass production | Mechanical processing | Machining NC milling machining NC turning machining Ceramic High precision |

| Mass production | Powder metallurgy | Ceramic |

| Mass production | Grinding processing | Plane grinding Cylindrical grinding |

| Surface treatment | Plating/Chemical conversion treatment | Nickel (barrel) Electroless nickel (barrel) |

| Surface treatment | Coating | Air-spray coating |

| Surface treatment | Barrel polishing | Barrel finishing (vibration) |

| Surface treatment | Other surface treatment | Vacuum deposition Coating Shot blast |

| Assembly/Inspection | Assembly | Precision equipment assembly Industrial machinery assembly |

| Assembly/Inspection | Inspection | Powder metallurgy |

| Parts manufacturing | Electrical part | Harness processing |

| Parts manufacturing | Spring | Compression coil spring Spring washer |

| Parts manufacturing | Bolt/Screw/Nut | Screw manufacturing Bolt manufacturing Nut manufacturing Screw manufacturing |

| Parts manufacturing | Other parts | Filter manufacturing Blade manufacturing |

| Product manufacturing | Production property | Machine tool manufacturing Other industrial machinery manufacturing Optical products manufacturing Food industry machinery manufacturing Industrial robot manufacturing Semiconductor manufacturing equipment manufacturing |

| Product manufacturing | Medical equipment manufacturing | Medical equipment manufacturing |

CE-RISE Co.,Ltd.™(Ceramics Industries)

CE-RISE Co.,Ltd.™(Ceramics Industries)