- Telephone number: +81-283-23-2633

- FAX: +81-283-22-7055

- Website

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Machining( Mass production / Mechanical processing ) |

|---|---|

|

|

NC turning machining( Mass production / Mechanical processing ) |

|

|

Complex turning machining( Mass production / Mechanical processing ) |

|

|

NC cylindrical grinding( Mass production / Grinding processing ) |

|

|

Machining/Handles small-scale production (order from 1 piece)( Development and production of prototype/Small-scale production / Machining ) |

|

|

Machining (horizontal)( Development and production of prototype/Small-scale production / NC machining ) |

|

|

Machining (vertical)( Development and production of prototype/Small-scale production / NC machining ) |

Icon

Company info

| Company name | Takenaka Co., Ltd. | Website URL | http://www.takenaka-tac.co.jp/ |

|---|---|---|---|

| Street address |

Sano Tochigi Japan

[See map] |

Person in charge | yonehara |

| Telephone number | +81-283-23-2633 | Fax number | +81-283-22-7055 |

| Capital | 53,000,000 JPY | Employees | 152 |

| Annual sales | Unregister | EMIDAS Member Number | 80611 |

| Type of manufacturing | Heavy electric machinery / Transportation equipment | ||

| Main 3 products |

|

||

PR message

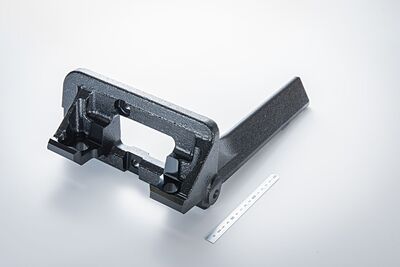

We manufacture products in a variety of fields, including automotive, construction machinery, and truck parts.

As a manufacturing company that supports the next generation, we are also actively working on our own technological development.

In order to meet the wide range of customer requests, we have introduced advanced production equipment, including large machining centers, and has built a flexible production system.

Furthermore, by combining the machining technology we have cultivated over many years with this latest equipment, we are able to quickly respond to all customer needs.

We are good in cutting cast and forged rough materials.

In addition to traditional iron-based rough materials, there has been a surge in demand in recent years for aluminum-based rough materials due to the trend toward weight reduction, as well as heat-resistant stainless steel for functionality and safety.

We also expertise in the processing and assembly of thin-walled, complex-shaped items that are prone to clamp distortion.

We are also actively challenging ourselves to process new rough materials and difficult-to-cut materials with the goal of enhancing various capabilities such as strength and weight reduction.

In addition, we work with machine tool manufacturers and tool manufacturers as necessary to develop unprecedented equipment and tools to meet the needs of our customers.

Processing experience for particular rough materials and difficult-to-cut materials

- High-strength ductile cast iron (FCD700, 800) - Heat-resistant stainless cast steel. 1.4848, 1.4837, KN4

- We excel at mass manufacture of 1,000 to 10,000 units each month.

Even when processing difficult-to-cut materials and complex-shaped products, we consider production preparations such as processing procedures, jigs, and setups that are intended to assure steady mass production even at the prototype review stage.

We develop ideal production processes that meet a variety of conditions such as raw materials, forms, dimensional tolerances, and numbers, and we endeavor to build the best production techniques that assure steady operation and efficiency while keeping QCD balanced.

Most recent update:2025-10-14

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Development and production of prototype/Small-scale production | Machining | General-purpose milling General-purpose lathe machining Tapping Gear hobber Machining/Handles small-scale production (order from 1 piece) Iron Stainless steel Aluminum alloy Magnesium alloy Broaching Casting |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC milling NC lathe machining Boring milling NC vertical lathe Combined lathe machining Machining (horizontal) |

| Development and production of prototype/Small-scale production | Grinding processing | NC cylindrical grinding Cylindrical grinding |

| Development and production of prototype/Small-scale production | Welding/Adhesive bonding | Arc welding |

| Development and production of prototype/Small-scale production | Casting | Sand casting cast iron Ductile cast iron 500g-5kg 5kg or more |

| Mass production | Mechanical processing | Machining NC milling machining NC turning machining Complex turning machining Broaching machining Ultra-thin High precision High strength |

| Mass production | Grinding processing | NC cylindrical grinding |

| Assembly/Inspection | Assembly | Auto parts assembly |