- Telephone number: +81-42-570-6891

- FAX: +81-42-570-6892

- Website

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Simultaneous 5-axis machining( Development and production of prototype/Small-scale production / Machining ) |

|---|---|

|

|

Combined lathe machining( Development and production of prototype/Small-scale production / NC machining ) |

|

|

5-face/5-axis machining( Development and production of prototype/Small-scale production / NC machining ) |

|

|

Simplified/Molding( Development and production of prototype/Small-scale production / Prototype processing ) |

|

|

Handles 3D processing( Development and production of prototype/Small-scale production / NC machining ) |

|

|

Aluminum alloy( Development and production of prototype/Small-scale production / Machining ) |

|

|

Plastic protocol machining( Development and production of prototype/Small-scale production / Prototype processing ) |

|

|

Stainless steel( Development and production of prototype/Small-scale production / Machining ) |

|

|

Titanium alloy( Development and production of prototype/Small-scale production / Machining ) |

|

|

Machining (resin)( Development and production of prototype/Small-scale production / Machining ) |

Icon

Company info

| Company name | Kodama Corporation Co., Ltd. | Website URL | https://www.kodamacorp.co.jp/ |

|---|---|---|---|

| Street address |

Hamura-shi Tokyo Japan

[See map] |

Person in charge | Kodama Shisaku |

| Telephone number | +81-42-570-6891 | Fax number | +81-42-570-6892 |

| Capital | 63,000,000 JPY | Employees | 28 |

| Annual sales | Unregister | EMIDAS Member Number | 81024 |

| Type of manufacturing | Industrial machinery / Transportation equipment / Medical equipment | ||

| Main 3 products |

|

||

PR message

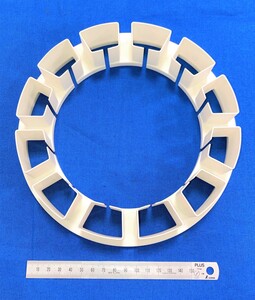

At Kodama Corporation's Prototyping Division, we view CAD/CAM as a key management tool. Using the TopSolid CAD/CAM system, we achieve streamlined, efficient, and standardized production practices. This approach allows us to contract-manufacture over 2,000 complex parts annually, meeting stringent quality and delivery standards, even for challenging geometries and hard-to-machine materials.

We work with a range of industries, including automotive, industrial machinery, aerospace, marine, and medical, supporting their R&D needs with reliable production solutions.

Supported Materials (Metals):

・Aluminum, stainless steel, Inconel, titanium, Hastelloy, Super Invar (Invar), pure nickel, tungsten alloys, iron, copper, etc.

Supported Materials (Resins):

・High-performance resins (PA66-GF30, PPS-GF40, PBT-GF30, PEEK-GF30, etc.)

・General-purpose resins (ABS, PP, PA, PMMA, etc.)

Our experienced sales staff, with extensive knowledge of materials and machining, offer technical proposals to enhance product functionality and reduce costs. In our design room, we use the 3D CAD/CAM system TopSolid to ensure smooth, integrated data flow, minimizing rework and maximizing efficiency and quick delivery.

With 15 advanced simultaneous 5-axis machining centers and complex processing machines, our state-of-the-art equipment operates unmanned 24/7, handling a wide range of products from intricate components to those up to 400 mm in size.

We provide end-to-end solutions for high-precision machining, including hard-to-machine materials and intricate shapes, as well as heat and surface treatments.

In quality assurance, our facilities are equipped with the latest measuring instruments in a controlled environment to ensure we meet all quality requirements.

Additionally, we offer a CAD/CAM business, selling TopSolid software series. For more information, visit TopSolid by Kodama Corporation. https://topsolid.kodamacorp.co.jp/

Most recent update:2025-08-22

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Injection molding die 3D modeling (plastic) NC data creation (plastic) |

| Designing | Jig and tool designing | General jig designing |

| Development and production of prototype/Small-scale production | Machining | Machining/Handles small-scale production (order from 1 piece) Iron Stainless steel Aluminum alloy Copper alloy Titanium alloy Nickel alloy Machining (resin) Simultaneous 5-axis machining Milling (resin) Lathe machining (resin) Handles microfabrication Handles microfabrication Titanium Brass |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC lathe machining 5-face/5-axis machining Combined lathe machining Handles 3D processing |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining |

| Development and production of prototype/Small-scale production | Welding/Adhesive bonding | Plastic bonding |

| Development and production of prototype/Small-scale production | Jig manufacturing | Jig and tool manufacturing |

| Development and production of prototype/Small-scale production | Prototype processing | Plastic protocol machining Small-size prototype manufacturing Vacuum injection molding Prototype/Small-lot molding Small-lot/Injection molding Simplified/Molding prototype mold |

| Die manufacturing | Plastic mold | Manufacturing NC data creation 3D modeling Below 60 t 60 - 300 t Cassette-type molding die |

| Surface treatment | Polishing/Lapping | Buffing |

| Surface treatment | Lap polishing | Lap polishing Lap mirror polishing |

![[Aluminum] Prototype with Complex 3D Shape Created Using 5-Axis & Multi-Axis Machining](/temp/400_300_2fb4823675026ca8b50a0666a41cc639.jpg)

![[Aluminum] Prototyping of Propellers, Screws, and Impellers using 5-Axis Machining and Multi-Axis Lathes specialized 3D shape processing](/temp/400_300_1552b38d9eaed05a5555d01f1087417c.jpg)

![[Aluminum] Prototype with Complex 3D Shape Created Using 5-Axis & Multi-Axis Machining](/temp/110_70_2fb4823675026ca8b50a0666a41cc639.jpg)

![[Aluminum] Prototyping of Propellers, Screws, and Impellers using 5-Axis Machining and Multi-Axis Lathes specialized 3D shape processing](/temp/110_70_1552b38d9eaed05a5555d01f1087417c.jpg)