- Telephone number: +81-42-570-6891

- FAX: +81-42-570-6892

- Website

- Basic Info

- Equipment

- Technology & Products

- Movie

- History, Philosophy & Quality

- EMIDASBLOG

- Map / HQ

Super Invar Processing

Industry

Semiconductor

Heat treatment and coating facilities

Space

Specifications

- Materials:Iron

Stainless steel

Nickel - Lots:1 - 100 lots

- Precision:0.1 mm - 1/100 mm

Conventional technologies/differences from other companies

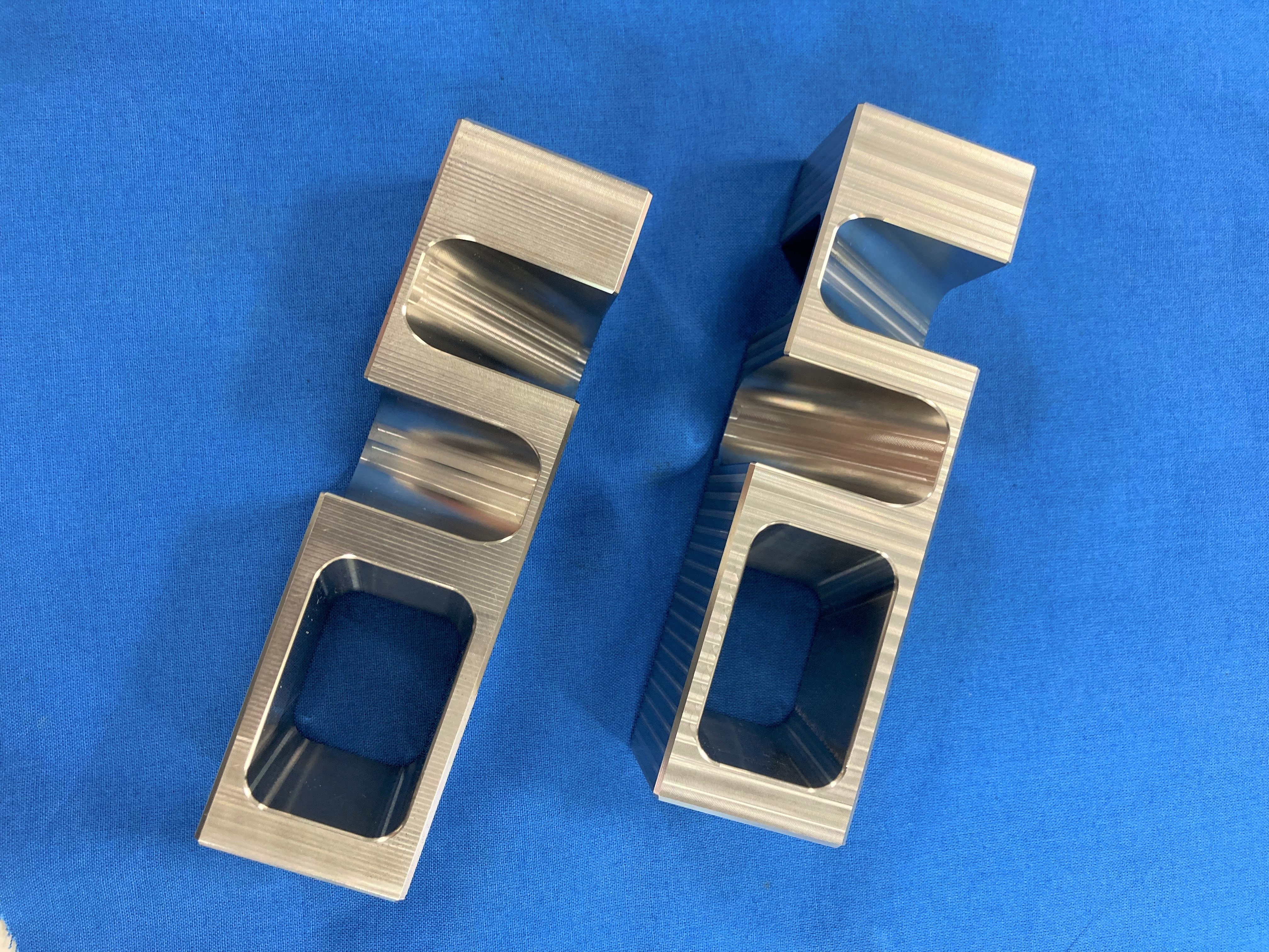

Sample Material: Super Invar (left), SUS304 (right)

Size: 150×50×50

Key Features:

・ Efficient and precise processing using 5-axis and multi-axis machining.

・ We can achieve the same quality for Super Invar as for SUS materials.

・ CAD/CAM-driven 5-axis machining is essential for processing that considers the burden on the cutting edges.

Supported Materials (Metals)

・ Aluminum

・ Stainless Steel

・ Inconel

・ Titanium

・ Hastelloy

・ Super Invar

・ Pure Nickel

・ Tungsten Alloy

・ Iron

・ Copper

Supported Materials (Plastics)

・ High-performance Resins (PA66-GF30, PPS-GF40, PBT-GF30, PEEK-GF30, etc.)

・ General-purpose Resins (ABS, PP, PA, PMMA, etc.)

Available Equipment

◎ 5-Axis Machines

◎ Makino DA300 (5-axis with pallet changer)

◎ DMGI DMC 60 U duoBLOCK (5-axis)

◎ Mori Seiki NMV5000 DCG (5-axis)

◎ Matsuura MAM72-63V (5-axis with pallet changer)

◎ Matsuura MX-330 (5-axis with pallet changer)

◎ GF Machining Solutions MIKRON HSM 600U (5-axis with pallet changer)

◎ GF Machining Solutions MIKRON HSM 400U (5-axis with pallet changer)

◎ Multi-Axis Machines

◎ Mori Seiki NT4250 DCG

◎ Okuma MALTUS B300II

◎ AMADA A-18S

Company info

| Company name | Kodama Corporation Co., Ltd. | EMIDAS Member Number | 81024 |

|---|---|---|---|

| Country | Japan | Street address |

Hamura-shi Tokyo Japan |

| Telephone number | +81-42-570-6891 | Fax number | +81-42-570-6892 |

| Employees | 63,000,000 JPY | Annual sales | |

| Employees | 28 | Person in charge | Kodama Shisaku |

| Type of manufacturing | Industrial machinery / Transportation equipment / Medical equipment | ||