- Telephone number: +81-276-22-6270

- FAX: +81-276-22-6278

- Website

With our high-mix, low-volume, quick-delivery manufacturing method and unique oil-free technology, we contribute to enhancing mold and machine productivity as a producer of high-precision pins, shafts, and bushings for molds and FA equipment!

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

NC cylindrical grinding( Development and production of prototype/Small-scale production / Grinding processing ) |

|---|---|

|

|

Machining/Handles small-scale production (order from 1 piece)( Development and production of prototype/Small-scale production / Machining ) |

|

|

Handles microfabrication( Development and production of prototype/Small-scale production / Machining ) |

|

|

NC lathe machining( Development and production of prototype/Small-scale production / NC machining ) |

|

|

Wire electric discharge machining( Development and production of prototype/Small-scale production / Electrical discharge machine ) |

|

|

Electric discharge machining( Development and production of prototype/Small-scale production / Electrical discharge machine ) |

|

|

Vacuum quenching( Surface treatment / Heat treatment ) |

|

|

Profile grinding( Development and production of prototype/Small-scale production / Grinding processing ) |

|

|

Centerless grinding( Development and production of prototype/Small-scale production / Grinding processing ) |

|

|

Stainless steel( Development and production of prototype/Small-scale production / Machining ) |

Icon

Company info

| Company name | Takano Co., Ltd | Website URL | https://www.kk-takano.co.jp/ |

|---|---|---|---|

| Street address |

Oota-shi Gunma Japan

[See map] |

Person in charge | 高野 |

| Telephone number | +81-276-22-6270 | Fax number | +81-276-22-6278 |

| Capital | 20,000,000 JPY | Employees | 80 |

| Annual sales | EMIDAS Member Number | 82001 | |

| Type of manufacturing | Industrial machinery / Transportation equipment / Medical equipment | ||

| Main 3 products |

|

||

PR message

TAKANO Co., Ltd. has been a metal mold supplier for 40 years now. We have combined our accumulated knowledge as a parts supplier and our technologies with the usage of cutting-edge equipment.This was done so that we could carry out integrated manufacturing within our own facility, beginning with stamping and continuing through heat treatment and grinding processing. By integrating the manufacturing processes, we have managed to fabricate standardized and made-to-order products within shorter lead time.

We also have been putting effort on developing new technologies and techniques to produce brand new products. In recent years, we have been working on developing an original company solid lubricant. The lubricant we developed allows us a multiple incorporation into the parts where needed. Besides, we made it possible to manufacture no-oil-supply products by using the lubrication stick. As a result of such an invention, we have received the title of “2009 Genkina Mozukuri Company 300.”

We will continue to work on improving the quality of products and services while reducing the cost and lead time to ensure high customer satisfaction.

“Standard Parts”

As we have been working on the reduction of lead time, the reduction of delivery time was also concerned.

Most of our short lead time products are listed under “Partner” in our Takano catalog.

○We have a variety of punch, button die, pilot-punch and burring punch products. When it comes to standard types, we can ship the products within 2 days.

○We also have guide post, stroke end block, lifter pin, guide pin, guide bush, nock pin, volt etc. in stock to ensure same day shipping and next day delivery.

“Made to order parts”

We have managed to manufacture made to order products while at the same time lowering the cost. This was possible by applying our ability to deliver a variety of standard products in short lead time with machines which are specialized to produce metal molds.

○We can manufacture products exceeding the length and/or shape of standard types.

○ We can implement made-to-order for pilots, burring punches, shoulder punches and button dies.

○Besides, we can manufacture made-to-order guide pins, guide bushes, lifter pins and lifter guide pins.

○In order to add grooves as well as any other additional processing for button pins, please contact us for more information.

○For larger lot sized products, we can deliver the products within a reasonable time period as well.

“No-Oil-Supply Parts Technology”

In recent years, most factories began working on reducing the usage of oil lubrication to become environmental friendly.

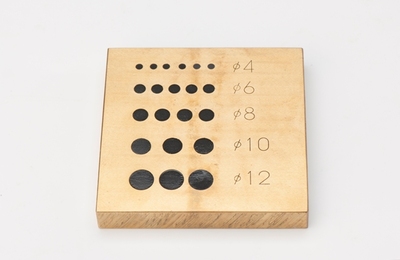

It has become possible to manufacture no-oil-supply products for anyone. The oil-stick is a lubricant which consists of a rich mixture of graphite, molybdenum disulfide and base oil made into a stick-like form. To use, firstly, drill a hole into the sliding source where no-oil-supply is necessary and then incorporate the oil-stick. It is easy to use for anyone and a new way to reduce lubrication problems. The oil-stick is our own unique product that can be used to turn most metal mold parts into no-oil-supply metal mold parts.

“CAM slider”

This is a product which allowed TAKANO to become a corporation.

This CAM unit exchanges parallel pressure for vertical pressure.

This technology is applicable for bending and drilling square materials.

○We have a variety of standards as well as sizes. The product can be applied in order to use nock holes, sliding parts and upper surface oil-less processing.

○We have DXF data and IJES data in addition to our catalog information. In other words, it is easy to install during the designing phase.

“Business Policy”

By having our main office in Oota-shi Gunma Prefecture, where most metal mold manufactures are located, we additionally have over 11 business offices around Kantou Koshinetsu and the Chubu area.

Most recent update:2025-04-24

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Development and production of prototype/Small-scale production | Machining | Machining/Handles small-scale production (order from 1 piece) Iron Stainless steel Handles microfabrication |

| Development and production of prototype/Small-scale production | NC machining | NC lathe machining |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining Electric discharge machining |

| Development and production of prototype/Small-scale production | Blank cutting | Laser marking |

| Development and production of prototype/Small-scale production | Grinding processing | NC plane grinding NC cylindrical grinding Plane grinding Form grinding Profile grinding Internal grinding Centerless grinding NC internal grinding |

| Development and production of prototype/Small-scale production | Jig manufacturing | General jig manufacturing Jig and tool manufacturing |

| Die manufacturing | Press die | Part processing NC data creation |

| Die manufacturing | Plastic mold | Part processing |

| Die manufacturing | Forging die | Forging die part processing |

| Surface treatment | Polishing/Lapping | Tool polishing |

| Surface treatment | Lap polishing | Lap polishing Lap mirror polishing Single-face lapping and polishing Dual-face lapping and polishing |

| Surface treatment | Heat treatment | Normalizing Vacuum annealing Quenching Vacuum quenching High frequency quenching Nitridation |

| Surface treatment | Other surface treatment | CVD (chemical vapor deposition) Coating Tool and die coating |

| Parts manufacturing | Machinery part | Shaft and roller manufacturing Mechanical parts |

| Product manufacturing | Production property | Machine tool manufacturing Stamp manufacturing |

| Product manufacturing | Others | Transportation equipment manufacturing |