- Telephone number: +81-774-53-8921

- FAX: +81-774-56-0263

- Website

- Basic Info

- Equipment

- Technology & Products

- Movie

- History, Philosophy & Quality

- EMIDASBLOG

- Map / HQ

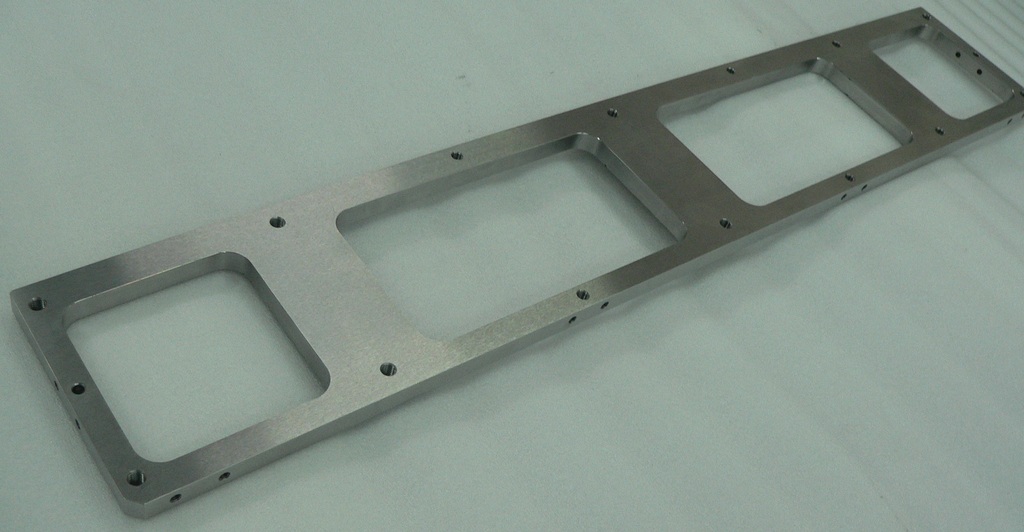

Distortion free processing of high hardness strained SUS303! Flatness 30 microns!

Industry

Semiconductor

Railway

Machine tools

Specifications

- Materials:Iron

Stainless steel

Titanium - Lots:1 - 100 lots

- Precision:0.1 mm - 1/100 mm

Conventional technologies/differences from other companies

With our distortion relieving technology, it is even possible to process high hardness material, up to a flatness of 30 microns.

The photo shows a SUS303 part (15 × 30 × 1200 mm) which surface is handled with nitro-carburizing to become HRC55.

After the heat treatment, strain occurs about 0.3 mm.

In addition, it is difficult to relieve distortions after the cutting of several rectangular-shaped holes. At Joyofuji Kogyo however we possess our own distortion relieving technology through which we succeed to finish our products with a flatness of 30 microns.

We can provide both the hardening of the surface’s parts (SUS303) as the full high hardening of the parts (SUS630), using a quenching process. Because we will relieve the distortion after the heat treatment.

Please feel free to contact us with all your questions and requests regarding distortion fee processing.

★Contact ★

TEL :0774-53-8921 FAX :0774-56-0263 Email :info@joyofuji.com

71-2 Nakamichiomote, Hirakawa Joyo City Kyoto 〒610-0101

Please feel free to ask for Ms. Kishimoto – Sales Management

Technical information website to pursue the VA/VE of design engineers

http://www.seimitukakou-costdown.com/

Order online: website of mechanical components and metal plate parts

http://www.kikaibuhin-tuuhan.com/

Company info

| Company name | Joyofuji Kogyo Co., Ltd. | EMIDAS Member Number | 84368 |

|---|---|---|---|

| Country | Japan | Street address |

Joyo-shi Kyoto Japan |

| Telephone number | +81-774-53-8921 | Fax number | +81-774-56-0263 |

| Employees | 18,500,000 JPY | Annual sales | 380,000,000 JPY |

| Employees | 25 | Person in charge | kazuhisa itashiki |

| Type of manufacturing | Machine tools / Industrial machinery / Medical equipment | ||