- Telephone number: +81-465-80-1588

- FAX: +81-465-81-7311

- Website

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Precision sheet metal machining( Development and production of prototype/Small-scale production / Sheet-metal processing ) |

|---|---|

|

|

3D modeling( Designing / Simulation ) |

|

|

CO2 laser machining ( Development and production of prototype/Small-scale production / Blank cutting ) |

|

|

Turret punch press processing( Development and production of prototype/Small-scale production / Blank cutting ) |

|

|

Bending (hydraulic)( Development and production of prototype/Small-scale production / Sheet-metal processing ) |

|

|

Projection welding( Development and production of prototype/Small-scale production / Welding/Adhesive bonding ) |

|

|

Etching( Development and production of prototype/Small-scale production / Blank cutting ) |

Icon

Company info

| Company name | Fukasawa Inc. | Website URL | |

|---|---|---|---|

| Street address |

Setagaya Kanagawa Japan

[See map] |

Person in charge | Mitsuru Takasu |

| Telephone number | +81-465-80-1588 | Fax number | +81-465-81-7311 |

| Capital | 20,000,000 JPY | Employees | 58 |

| Annual sales | 800,000,000 JPY | EMIDAS Member Number | 87199 |

| Type of manufacturing | Home electrical appliances / Telecommunication equipment / Medical equipment | ||

| Main 3 products |

|

||

| Primary clients |

|

||

PR message

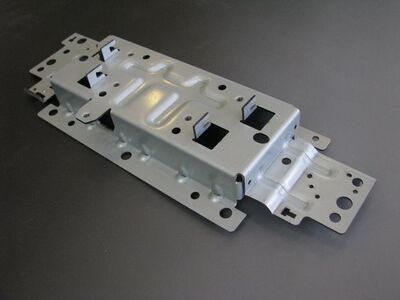

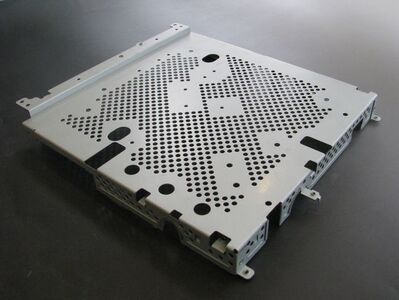

Metal sheet processing with a high-degree of precision and flatness

Our firm specializes in manufacturing electronic equipment components for e.g. O.A. equipment, flat panel TVs, household gaming devices, robots, computer parts etc.

We can respond to a variety of requests, for instance, innovating, prototype manufacturing, mass production, small lot manufacturing etc.

In addition to primary processing, we also have skills in second hand processing, namely, laser cutting, turret punch pressing and surface trimming after welding (require subcontracted companies' plating, painting and silk printing technologies).

Even if deep or complicated drawings are required, we can deliver products with a high-degree of precision and flatness by applying laser cutting and combined machine processing after molding. We also support short delivery time for drawn and bent metal molds by utilizing our processing technologies and developing simplified molds.

Paper less/2D/3D. As we have fully integrated all the data gathered from CAD to our processing machines, products are as accurate as they can get.

We support most inquiries with or without drawings. Please consider contacting Fukasawa Works Ltd.

In addition to what is stated above, we also can take orders from, as little as, a lot with quotation (ordering only a quotation is welcomed).

We support ASSY.

Any products we manufacture in addition to caulking, press fitting, rivets and welding (including spot welding, TIG and projection welding) are examined with digital vernier caliper, CMM and / or a non-contact 3D scanner. We also support XRF environment-related substance inspection if the manufactured products require it.

ISO9001: In 2008, we have obtained the Sony Corp. Ltd., Green Partner.

An inspection certificate will be attached to all manufactured products delivered by Fukasawa Works Ltd.

If environment-related information is required to be attached to the products (MSDS, ICP, inspection certificate etc.), please feel free to ask.

Most recent update:2025-05-01

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Progressive die designing (light electrical) Progressive die designing (auto) Drawing metal press die designing General metal press die 3D modeling (press) NC data creation (press) |

| Designing | Product and part designing | Model designing Medical equipment designing Measurement/testing device designing External design |

| Designing | Jig and tool designing | General jig designing Welding jig designing Mass production jig designing |

| Designing | Test | Specimen processing Chemical analysis |

| Designing | Simulation | 3D modeling |

| Development and production of prototype/Small-scale production | Machining | General-purpose lathe machining Rolling Iron Stainless steel Aluminum alloy Titanium Brass |

| Development and production of prototype/Small-scale production | NC machining | NC milling NC lathe machining Machining (horizontal) Handles 3D processing |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining |

| Development and production of prototype/Small-scale production | Sheet-metal processing | Precision sheet metal machining Chassis manufacturing Sheet metal protocol manufacturing Bending (over 3.0 m) Mirror surface machining Hair line machining Bending (hydraulic) Bending (servo) Thin wall (Thickness |

| Development and production of prototype/Small-scale production | Blank cutting | Turret punch press processing Shearing CO2 laser machining Laser marking Etching Microfabrication (laser machining ) Nitrogen cutting Thin plate (below 6 mm) Stainless steel Copper/Aluminum Precision cutting |

| Development and production of prototype/Small-scale production | Welding/Adhesive bonding | Spot welding TIG welding (argon welding) Arc welding Projection welding |

| Development and production of prototype/Small-scale production | Jig manufacturing | General jig manufacturing Welding jig manufacturing Mass production jig manufacturing |

| Development and production of prototype/Small-scale production | Prototype processing | Welding Bending Chassis prototype manufacturing Prototype/Small-lot molding Simplified/Molding |

| Die manufacturing | Press die | Designing Manufacturing Part processing NC data creation 3D modeling Drawing die Bending die Blanking die Progressive die Single press die Over 300 t Compound die |

| Mass production | Metal press | Drawing Bending Blanking Stainless steel Aluminum Copper Thickness Single press (80 - 200 t) Single press (200 - 500 t) |

| Mass production | Mechanical processing | NC milling machining NC turning machining Tapping machining Wire machining Rolling machining |

| Surface treatment | Plating/Chemical conversion treatment | Nickel (barrel) Chromium (barrel) Black chromium (barrel) Chromate (general) Nickel (rack) Gold/Silver plating Black chromium (rack) Alumite (anode oxidation) Electroless nickel (rack) Chemical conversion coating Iron Copper Brass Aluminum Stainless steel Other anti-rust treatments Colored alumite Hard alumite Unichromate (white) Black nickel |

| Assembly/Inspection | Assembly | Precision equipment assembly |

| Assembly/Inspection | Inspection | Measuring |

| Parts manufacturing | Machinery part | Optical parts manufacturing |

| Product manufacturing | Medical equipment manufacturing | Medical equipment manufacturing |