- Telephone number: +81-54-340-6631

- FAX: +81-54-340-5571

- Website

★☆★Please entrust us with the manufacturing of mold parts, jig and tool production, precision parts production, micromachining, blade production, bespoke product production, prototype development, and cutting processing.★☆★

Products, Expertise & Unique Technical Info

Manufacturing category info

|

|

Manufacturing( Die manufacturing / Press die ) |

|---|---|

|

|

Blanking die( Die manufacturing / Press die ) |

|

|

Mass production jig designing( Designing / Jig and tool designing ) |

|

|

Mass production jig manufacturing( Development and production of prototype/Small-scale production / Jig manufacturing ) |

|

|

Blade manufacturing ( Parts manufacturing / Other parts ) |

|

|

Can manufacturing( Development and production of prototype/Small-scale production / Sheet-metal processing ) |

|

|

Handles microfabrication( Development and production of prototype/Small-scale production / Machining ) |

|

|

Mirror polishing( Surface treatment / Polishing/Lapping ) |

|

|

Auto parts assembly( Assembly/Inspection / Assembly ) |

|

|

General jig designing( Designing / Jig and tool designing ) |

Icon

Company info

| Company name | SHIMIZU TRYM PRECISION INC. | Website URL | http://www.shimizutrym.co.jp/ |

|---|---|---|---|

| Street address |

Shizuoka-shi Shizuoka Japan

[See map] |

Person in charge | Sato |

| Telephone number | +81-54-340-6631 | Fax number | +81-54-340-5571 |

| Capital | Employees | 14 | |

| Annual sales | EMIDAS Member Number | 87724 | |

| Type of manufacturing | Measuring machinery / Industrial machinery / Electronic parts | ||

| Main 3 products |

|

||

PR message

[Business outline]

■Mold production, press mold parts production, punching die, bending, drawing

■Various jigs design/production (inspection jigs, assembly jigs, receiving jigs, jig parts)

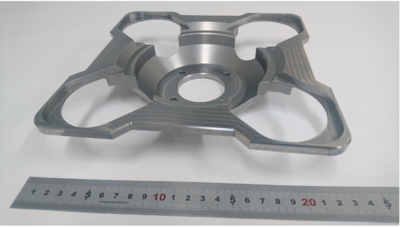

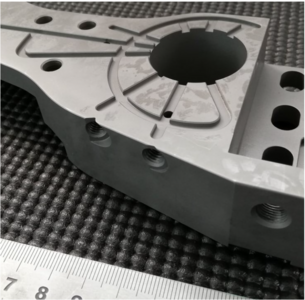

■Various metal/non-metal parts production (precision parts, micro parts, ultra-precision parts, high hardness material parts, metal parts, plastic parts, filling machine parts, 3D shape parts, equipment parts, FA parts)

■Blades, blade molds, punching dies, cutting tools, cuts

■Prototype development product/custom product production

【Features】

■Molds, jigs, various parts production, blades, blade molds, cutting blades, prototype development, custom-made product production

We supply a wide range of industries, including vehicles, semiconductors, medical care, pharmaceuticals, aerospace, food, electronics, and optics.

☆☆☆Recently, we have been incorporating various parts for semiconductor manufacturing equipment and semiconductor inspection equipment, and we have built a mass production system and are available 24 hours a day.

《Materials we can handle》

Aluminum: A5052 A2017 A6061 A7075

Iron: SS400 S50C SCM440 SKS3 SDK11 SKD61 DC53

NAK55 G-STAR HPM1 HPM38

Stainless steel: SUS303 SUS304 SUS316 SUS316L

Copper: Oxygen-free copper, tough pitch copper, brass, phosphor bronze, carbide, various resins, etc.

[Lots]

We handle prototypes, small lots, medium lots, mass production, complete set of parts, and complete set of jigs flexibly.

We manage a wide range of procedures, from general tolerances to dimensional precision processing on the order of 1000 minutes (micron level) in a constant temperature room, while maintaining the quality and cost that our clients expect.

[Equipment]

We also specialize in wire cutting, electric discharge, small hole machining, lathes, surface polishing, 3D coordinate measuring machines, and complex machining that utilizes a variety of equipment.

We flexibly respond to requests such as wire cutting additional machining on supplied materials.

We have precision processing room with consistent temperature and humidity (23°C ± 0.5°C 24 hours a day, 365 days a year) as well as a number of high-speed rotating machining equipment.

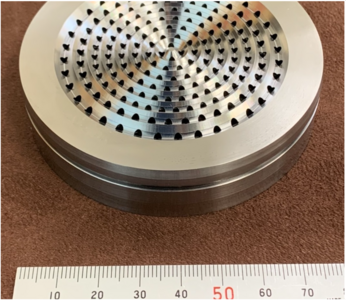

Product example:

"polish-less" mirror finish that eliminates the need for high-precision cutting and manual polishing,

direct engraving of difficult-to-cut materials, cutting of high-hardness materials, shape cutting, ultra-small diameter hole machining, mirror finishing, etc.

We give quotations starting with a single item order.

Even if there are no drawings, our machining specialists will address your request.

Our ability to give VA/VE proposals for machining and attain the quality and cost requested by clients is one of our strengths, since we have technical experts that are knowledgeable with machining.

In addition, we can create jigs, etc.

If you have any issues such as:

・VA/VE proposal for processing

・Production without drawing

・Wire cuts and holes additional work on only one part

・Cost reduction

・Projects with short delivery times.

・Arrange parts separately from multiple companies.

・Mold durability improvement

Please contact Shimizu Trym Precision ★

We will respond quickly.

■Precision mold parts production

We manufacture a wide range of mold parts, including punching dies, bending dies, drawing dies, forging dies, and punching dies for presses.

We handle molds for a variety of industries, including medical equipment, automotives, and electronic equipment.

Furthermore, precise temperature control allows for anything from high-precision molds to mirror finishes.

【Contact us】

Shimizu Trym Precision Inc.

421-1 Nagasaki Shinden, Shimizu-ku, Shizuoka-shi, Shizuoka

TEL: +8154-340-6631

FAX: +8154-340-5571

Person in charge: Sato

Please do not hesitate to contact us, even for single item order.

Contact us by email: eigyo@shimizutrym-pc.co.jp

Homepage: http://www.shimizutrym.co.jp/

Youtube channel: https://www.youtube.com/channel/UC4MV57eAu4ybSRV3ket2-Tw

Most recent update:2025-04-03

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Forging die designing Casting die designing Injection molding die Progressive die designing (auto) Drawing metal press die designing Transfer press die designing General metal press die 3D modeling (press) 3D modeling (plastic) NC data creation (press) NC data creation (plastic) |

| Designing | Jig and tool designing | General jig designing Mass production jig designing |

| Designing | Simulation | Fluid-fluid heat Structure |

| Development and production of prototype/Small-scale production | Machining | General-purpose milling General-purpose lathe machining Deep hole drilling Gear hobber Thread-cutting Machining/Handles small-scale production (order from 1 piece) Iron Stainless steel High rigid material Aluminum alloy Copper alloy Titanium alloy Nickel alloy Machining (resin) Sintered metal Sintered metal Keyway milling Automatic lathe Milling (resin) Lathe machining (resin) Casting Handles microfabrication Handles microfabrication Titanium Urethane Brass |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC milling NC lathe machining Combined lathe machining Handles 2.5-dimensional processing Handles 3D processing |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining Micro hole machining Electric discharge machining |

| Development and production of prototype/Small-scale production | Sheet-metal processing | Pipe machining Can manufacturing Precision sheet metal machining Sheet metal protocol manufacturing Angle machining Deburring Coating Mirror surface machining 3D pipe machining Can manufacturing (over 5 m) Thin wall (Thickness |

| Development and production of prototype/Small-scale production | Grinding processing | NC plane grinding Plane grinding |

| Development and production of prototype/Small-scale production | Welding/Adhesive bonding | Spot welding TIG welding (argon welding) Arc welding Brazing YAG laser machining |

| Development and production of prototype/Small-scale production | Jig manufacturing | General jig manufacturing Mass production jig manufacturing Jig and tool manufacturing |

| Development and production of prototype/Small-scale production | Prototype processing | Plastic protocol machining Punching Welding Small-size prototype manufacturing Prototype/Small-lot molding Small-lot/Injection molding Simplified/Molding prototype mold |

| Die manufacturing | Press die | Designing Manufacturing Part processing Plate machining Die set machining NC data creation 3D modeling Drawing die Bending die Blanking die Forming die Fine blanking die Multi forming die Roll forming die Shaving die Progressive die Transfer press die Single press die Press robot die Below 60 t Sash molding die Compound die |

| Die manufacturing | Plastic mold | Designing Manufacturing Part processing Plate machining Mold base machining NC data creation 3D modeling Injection molding die Insert molding die Below 60 t 60 - 300 t Aspherical lens molding die manufacturing Injection molding die for microfabrication (5 mm or smaller) Core and cavity machining |

| Die manufacturing | Glass mold | Spherical lens molding die |

| Die manufacturing | Powder metallurgy mold | Manufacturing Metal die High rigid die |

| Mass production | Mechanical processing | Machining NC milling machining NC turning machining Complex turning machining Micro-hole machining Iron Stainless Aluminum alloy Copper alloy Turning machining(plastic) Fine particle material accepted Urethane High precision |

| Mass production | Plastic | PVC (polyvinyl chloride) General-purpose material PMMA (polymethyl methacrylate) Engineering plastic PBT (polybutylene terephthalate) PPS (polyphenylene sulfide) PI (polyimide) PEEK (polyetheretherketone) Urethane resin PU (polyurethane) Below 60 t PES (polyethersulfone) EP (epoxy) |

| Mass production | Forging | Cold forging Iron Aluminum Brass 500 g - 5 kg Corson alloy |

| Mass production | Grinding processing | NC plane grinding Plane grinding |

| Mass production | Sheet-metal processing | Pipe processing Can-making Precision sheet metal processing Sheet metal prototype manufacturing Angle processing Deburring process Mirror surface material processing Can making (more than 5m) Thin (t0.5 or less) / Small sheet metal processing Bending process |

| Mass production | Blank cutting | Laser marking YAG laser processing Cutting process Water jet processing CO2 laser processing UV laser machining Dry etching (outer shape processing) Etching Microfabrication (laser) Thin plate 6 mm or less Thick plate 6 mm or more stainless Copper / aluminum |

| Mass production | Welding / welding | Spot welding TIG welding (argon welding) Arc welding fixing with wax YAG laser processing |

| Surface treatment | Plating/Chemical conversion treatment | Nickel (barrel) Chromium (barrel) Black chromium (barrel) Zinc (barrel) Chromate (general) Rhodium Nickel (rack) Gold/Silver plating Chromium (rack) Black chromium (rack) Zinc (rack) Alumite (anode oxidation) Nickel chromium (rack) Acid pickling Parkerizing (phosphate film) Electroless nickel (barrel) Electroless nickel (rack) Tin-zinc alloy plating (rack) Trivalent Chromate (barrel plating) Iron Copper Brass Aluminum Stainless steel Other anti-rust treatments Hard chromium (rack) Degreasing Black oxide finish Colored alumite Hard alumite Hot-dip galvanizing (small-size Unichromate (white) Black chromate (black/green) Nickel (hoop) Gold(Hoop) Electroless nickel (large) Black nickel Hard chrome (barrel) Hard chrome (large) Hard alumite (large) |

| Surface treatment | Coating | Metal coating |

| Surface treatment | Polishing/Lapping | Electropolishing Chemical polishing Blade polishing Buffing Mirror polishing |

| Surface treatment | Lap polishing | Lap polishing Lap mirror polishing Single-face lapping and polishing Dual-face lapping and polishing |

| Surface treatment | Heat treatment | Normalizing Vacuum normalizing Annealing Full annealing Stress relief annealing (SR treatment) Straightening annealing Vacuum annealing Quenching Salt bath quenching Vacuum quenching Austempering High frequency quenching Solution heat treatment Sub-zero treatment Carburized quenching Salt bath soft nitriding (tufftriding) Nitridation Gas nitrocarburizing |

| Surface treatment | Other surface treatment | Coating Teflon coating Shot peening/WPC Buffing Shot blast Sound blast DLC coating Deburring |

| Assembly/Inspection | Assembly | Precision equipment assembly Office equipment assembly Auto parts assembly Industrial machinery assembly Toy and sundries assembly |

| Assembly/Inspection | Repair | Die repair |

| Assembly/Inspection | Inspection | Metal press Plastic Measuring |

| Parts manufacturing | Machinery part | Gear manufacturing Vacuum components manufacturing Connection parts manufacturing Optical parts manufacturing Shaft and roller manufacturing |

| Parts manufacturing | Electric board and electronic part | Electronic parts assembly and wiring |

| Parts manufacturing | Other parts | Metallic mesh manufacturing Blade manufacturing |

| Auto parts manufacturing | Drive system part | Transmission |

| Auto parts manufacturing | Engine | Cooling system Fuel system Muffler Radiator parts |

| Auto parts manufacturing | Interior part | Communication accessories Audio components |

| Product manufacturing | Production property | Machine tool manufacturing Other industrial machinery manufacturing Electrical machinery and apparatus manufacturing Energy-saving equipment/Automatic instrument manufacturing Packaging machinery manufacturing Measurement/testing devices manufacturing Cardboard box manufacturing Optical products manufacturing Vacuum equipment manufacturing Food industry machinery manufacturing Chemical industry machinery and equipment manufacturing Industrial robot manufacturing Blade manufacturing Semiconductor manufacturing equipment manufacturing |

| Product manufacturing | Medical equipment manufacturing | Medical equipment manufacturing Inspection and testing devices |

| Product manufacturing | Food industry machinery manufacturing | Other food industry machinery manufacturing |

| Product manufacturing | Others | Telecommunication equipment manufacturing |

![[Machined SUS316L 3D shape, surface roughness, chemical/medical business]](/temp/400_300_ed45ed5450953119969529a6ce4d1eab.jpg)

![[Shimizu Trym Precision actively handles a wide range of processing, including processing with tight dimensional tolerances and processing of complicated forms]](/temp/400_300_75b412ef48880f718fbb103db1dd4790.png)

![[Shimizu Trym Precision handles not just precision parts, but also precision molds for a variety of industries☆]](/temp/400_300_9d9f432d48c652d0b952af6a45517d6e.png)

![[Achieved high precision roundness even in prone to distortion forms☆]](/temp/400_300_e9c510234b954d85bb2242a04de9158b.png)

![[Machined SUS316L 3D shape, surface roughness, chemical/medical business]](/temp/110_70_ed45ed5450953119969529a6ce4d1eab.jpg)

![[Shimizu Trym Precision actively handles a wide range of processing, including processing with tight dimensional tolerances and processing of complicated forms]](/temp/110_70_75b412ef48880f718fbb103db1dd4790.png)

![[Shimizu Trym Precision handles not just precision parts, but also precision molds for a variety of industries☆]](/temp/110_70_9d9f432d48c652d0b952af6a45517d6e.png)

![[Achieved high precision roundness even in prone to distortion forms☆]](/temp/110_70_e9c510234b954d85bb2242a04de9158b.png)