- Telephone number: +81-58-389-1811

- FAX: +81-58-389-1812

- Website

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Cylindrical grinding( Development and production of prototype/Small-scale production / Grinding processing ) |

|---|---|

|

|

Internal grinding( Development and production of prototype/Small-scale production / Grinding processing ) |

|

|

Plane grinding( Development and production of prototype/Small-scale production / Grinding processing ) |

|

|

Profile grinding( Development and production of prototype/Small-scale production / Grinding processing ) |

|

|

Jig grinding( Development and production of prototype/Small-scale production / Grinding processing ) |

|

|

Cylindrical mirror grinding( Development and production of prototype/Small-scale production / Grinding processing ) |

|

|

Medical equipment manufacturing( Product manufacturing / Medical equipment manufacturing ) |

Icon

Company info

| Company name | OHORI GRINDING COMPANY | Website URL | https://www.ohorigrinding.com |

|---|---|---|---|

| Street address |

Kakamigahara city Gifu Japan

[See map] |

Person in charge | Keizo Ohori |

| Telephone number | +81-58-389-1811 | Fax number | +81-58-389-1812 |

| Capital | 8,000,000 JPY | Employees | 50 |

| Annual sales | Unregister | EMIDAS Member Number | 87912 |

| Type of manufacturing | Machine tools / Industrial machinery / Transportation equipment | ||

| Main 3 products |

|

||

| Primary clients |

|

||

PR message

Ohori Grinding Company is a process manufacturer specializing

in ultra-high precision grinding of components made of metal

and other materials. Our highly skilled technicians finish off the products using their delicate senses and ensure quality with a top-of-the-line inspection system.

We have refined our techniques in machining for a broad range of fields, including aerospace, automotive as well as F1 racing, medicine, and machine tools. We can meet customer requests, from working with extremely small components, requiring grinding in millimeters, to large objects, several meters in size.

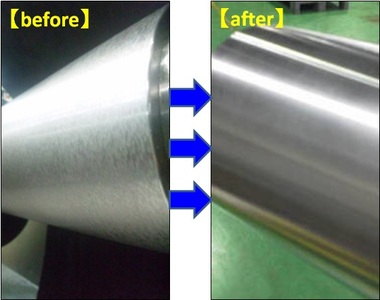

Our strengths is our ability to grind delicate materials that other manufacturers cannot machine, such as aluminum, stainless steel, and Inconel.

Our philosophy is that “anything less than 1/100 mm is the realm

of a skilled technician,” and each day our grinding technicians are improving their processing techniques. This allows them to machine parts to an accuracy of 0.001 mm.

At Ohori Grinding Company, we have approximately 40 skilled grinding technicians engaged in processing parts requested by clients. The most difficult part of the grinding process is controlling the quantity of heat. External grinding of cylindrical-shaped components as well as internal grinding is particularly challenging for long metal shapes, as deflection and curvature can occur. This is an area, in which Ohori Grinding excels. That kind of processing is difficult even when using a NC program controlled by a computer and can only be done through the delicate operation of a skilled technician’s hands.

We excel in a wide variety of services such as:

External Grinding

Inner Grinding

Surface Grinding

Taper Grinding

Profile Grinding

Jig Grinding

Of course, if you provide us with drawings, we will deliver the finished product. We have various partners in manufacturing.

Ohori Grinding uses the very latest inspection equipment as well as a thermostatic chamber inside our factory, where inspection can be done reliably.

We apply the quality standards ISO 9001: 2015 and EN 9100: 2016

Most recent update:2026-01-16

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Development and production of prototype/Small-scale production | Grinding processing | NC plane grinding NC cylindrical grinding Plane grinding Cylindrical grinding Profile grinding Jig grinding Cylindrical mirror grinding Internal grinding Thread grinding NC internal grinding |

| Development and production of prototype/Small-scale production | Jig manufacturing | General jig manufacturing Mass production jig manufacturing Jig and tool manufacturing |

| Mass production | Grinding processing | NC plane grinding NC cylindrical grinding Plane grinding Cylindrical grinding Profile grinding Jig grinding Internal grinding NC internal grinding |

| Surface treatment | Plating/Chemical conversion treatment | Alumite (anode oxidation) Hard chromium (rack) Hard alumite Hard chrome (large) Hard alumite (large) |

| Surface treatment | Polishing/Lapping | Mirror polishing |

| Surface treatment | Lap polishing | Lap polishing Lap mirror polishing |

| Surface treatment | Heat treatment | Vacuum quenching High frequency quenching Sub-zero treatment Carburized quenching |

| Assembly/Inspection | Repair | Machine tool repair |

| Parts manufacturing | Machinery part | Bearing manufacturing Crank shaft manufacturing Shaft and roller manufacturing |

| Parts manufacturing | Bolt/Screw/Nut | Screw manufacturing Screw manufacturing |

| Parts manufacturing | Other parts | Model manufacturing Blade manufacturing |

| Product manufacturing | Medical equipment manufacturing | Medical equipment manufacturing Surgical instruments Dental products |