- Basic Info

- Equipment

- Technology & Products

- Movie

- History, Philosophy & Quality

- EMIDASBLOG

- Map / HQ

What's Induction Hardening Vol. 1

Industry

---

Specifications

- Materials: ---

- Lots: ---

- Precision: ---

Conventional technologies/differences from other companies

Our advisor Junji Minoue was featured in the magazine {Shoukou Shinkou]

published by the Osaka Prefectural Manufacturing & Industrial Association.

Here is his submission in the Manufacturing Q&A section.

*********************************************************************************

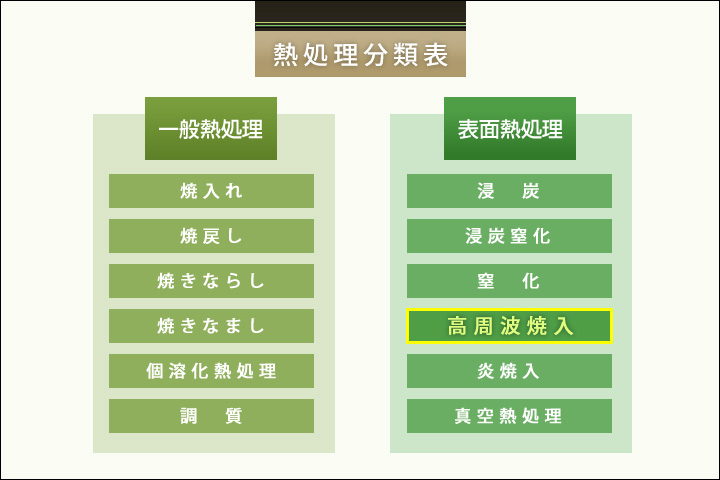

[Induction Hardening] is one type of heat treatment of steel products,

but it is especially known as a treatment for only selected sections of

a part or for surface hardness of only a few millimeters depth.

This is why induction hardening is also called surface hardening.

Induction hardening is a process that uses only electricity as an energy source

and can be applied to a wide range of steel products including

production machinery, machine tools, construction equipment, automobiles,

ship axles, gears, and bearings.

The heating principle behind induction hardening, the same as that of

induction heating cookers, is to rapidly and directly heat the workpiece

by magnetic induction without contact.

By using large volume power sources ranging from several 100kWs to

over 1000kW,the workpiece surface is heated to almost 1000˚C

in only a few seconds.

Hardening methods have been long used for blades and swords.

After heating the blades to temperatures high than red heat, they were

rapidly quenched in water or other liquids to harden them.

As steel parts are hardened, they also become more brittle.

However, induction hardening only hardens a few millimeters of

the part's surface, retaining the original material's flexibility.

This make induction hardening an ideal heat treatment process.

Also, by hardening the surface, rotation, abrasion, and tensile strength

are increased, making induction hardening ideal for making stronger,

more lightweight industrial parts with an energy efficient process.

In the automobile industry, as the demand for lower carbon emissions and

higher safety and endurance grow larger year by year, parts for engines,

transmission, suspension, and steering must be lighter and stronger.

Induction heating is a valuable process that achieves these two seemingly

contradictory requirements.

In addition, in comparison to fuel-powered heating machines, induction

hardening machines contribute to a cleaner work environment, machine

start and stop can be done at will, and in-line automatization is done easily.

~What's Induction Hardening Vol. 1~

Company info

| Company name | Fuji Electronics Industry Co., Ltd. | EMIDAS Member Number | 88995 |

|---|---|---|---|

| Country | Japan | Street address |

Oihara, Yao Osaka Japan |

| Telephone number | +81-72-991-1361 | Fax number | +81-72-991-1309 |

| Employees | 80,000,000 JPY | Annual sales | |

| Employees | 130 | Person in charge | Noumi |

| Type of manufacturing | Machine tools / Industrial machinery / Transportation equipment | ||

| Primary clients |

|

||

Fuji Electronics Industry Co., Ltd.

Fuji Electronics Industry Co., Ltd.