- Basic Info

- Equipment

- Technology & Products

- Movie

- History, Philosophy & Quality

- EMIDASBLOG

- Map / HQ

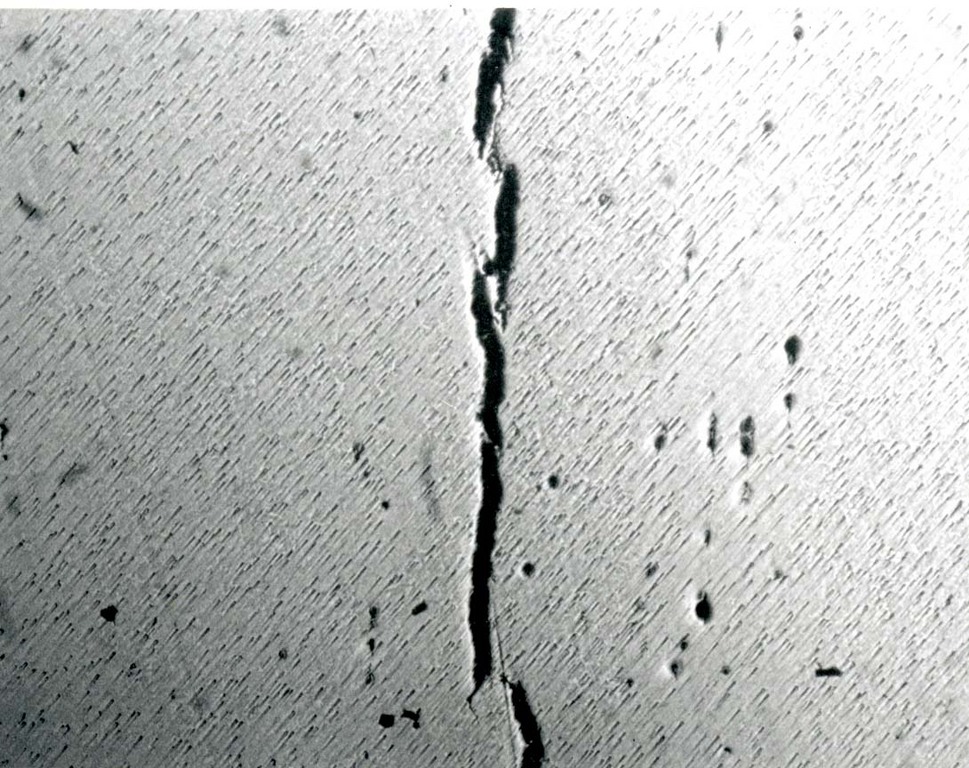

Induction Hardening Cracking Magnetic Particle Testing

Industry

Automobile (trial production)

Automobile (mass production)

Specifications

- Materials:Steel

- Lots: ---

- Precision: ---

Conventional technologies/differences from other companies

For our customers facing induction hardening cracking, let us at Fuji Denshi

resolve your issues.

● Magnetic Particle Testing

A non-destructive inspection method applicable for surface cracks,

forging cracks, hardening cracks of magnetic materials.

● Principle of Magnetic Particle Testing

Similar to magnetizing a nail by winding it with a conducting enamel thread,

the workpiece to be inspected is magnetized. If there are cracks,

each side of the crack will have opposite polarities.

By applying colored or flourescent iron powder liquid to the workpiece,

the powder accumulates in the cracks, making them visible.

● Demagnetization

After inspection, the workpiece must be premagnetized before post-

processing such as grinding.

At Fuji Denshi, our veteran technicians use our magnetic particle testing

equipment to locate cracks undetectable by color spray.

Please contact us with your concerns about cracking.

~ Induction Hardening Cracking Magnetic Particle Testing ~

Company info

| Company name | Fuji Electronics Industry Co., Ltd. | EMIDAS Member Number | 88995 |

|---|---|---|---|

| Country | Japan | Street address |

Oihara, Yao Osaka Japan |

| Telephone number | +81-72-991-1361 | Fax number | +81-72-991-1309 |

| Employees | 80,000,000 JPY | Annual sales | |

| Employees | 130 | Person in charge | Noumi |

| Type of manufacturing | Machine tools / Industrial machinery / Transportation equipment | ||

| Primary clients |

|

||

Fuji Electronics Industry Co., Ltd.

Fuji Electronics Industry Co., Ltd.