- Telephone number: +84-24-6684-4282

- FAX: +84-24-3734-9267

- Website

Yamaguchi Vietnam Joint Stock Company is an engineering company that specializes in manufacturing of precision machined parts and components. We were founded in February 2011.

Products, Expertise & Unique Technical Info

|

Icon

Company info

| Company name | YAMAGUCHI VIETNAM JOINT STOCK COMPANY | Website URL | http://mechanical.yamaguchi.vn/ |

|---|---|---|---|

| Street address |

Hoai Duc District Ha Noi Socialist Republic of Vietnam

[See map] |

Person in charge | Xuyen |

| Telephone number | +84-24-6684-4282 | Fax number | +84-24-3734-9267 |

| Capital | 2,130,000 $ | Employees | 450 |

| Annual sales | EMIDAS Member Number | 89647 | |

| Type of manufacturing | Jigs and tools / Machine tools / Industrial machinery | ||

| Main 3 products |

|

||

PR message

Yamaguchi Vietnam Joint Stock Company is an engineering company that specializes in manufacturing of precision machined parts and components. We were founded in February 2011.

Yamaguchi is a team of professional, experienced, and fully qualified technicians, who are extremely passionate and interested in your ideas. We are constantly focusing all of our efforts on research and development, ready to work 24/7 to guarantee customer satisfaction and build sustainable relationships by providing you a highly accurate, quick, and economical production.

Yamaguchi creates company growth in harmony with nature and society. We take our social responsibility seriously. To this end, we develop and manufacture products that benefit people and the environment.

Yamaguchi has received ISO 9001:2015 and ISO 14001:2015 certificates.

OUR CAPABILITIES

Our products & services

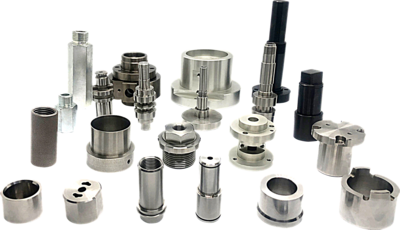

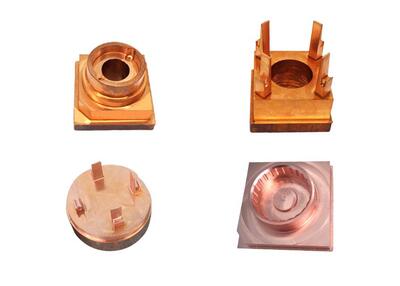

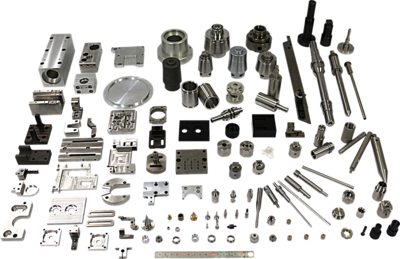

• Machining precision parts

- We offer a diverse range of CNC machining in single items as well as mass production, working with a variety of materials including:

+ Stainless steel SUS316, SUS304, SUS303, SUS440C,... One of the main

advantages is our ability to machine on stainless steel material.

+ Steel S55C, S50C, S45C, SS400,...

+ Steel SKD11, SKD61, NAK80, P20,...

+ Aluminium A2017, A7075, A6061, A5052,...

+ Copper & Brass C3604, C1100, Becu,...

+ Plastic POM, MC, PMMA, PET, Peek, Bakelit,...

- Maximum workpiece dimensions:

+ CNC lathe (X-Z) up to 450x1,000 mm

+ CNC milling machine (X-Y-Z) up to 1,050x510x460 mm

- We can produce a maximum capacity of 500,000 products per month.

- Accuracy: ± 0.01 mm

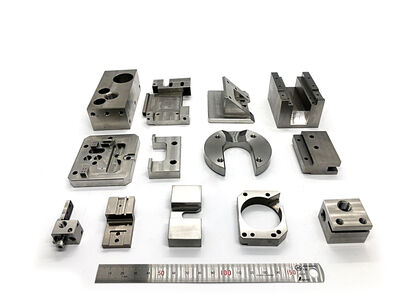

• Jig design & fabrication

We outsource post-processing operations:

• Surface treatment

- Black oxide coating

- Zinc plating

- Nickel plating

- Chrome plating

- Anodizing

- Nitriding

- Carburizing

• Heat treatment

- Vacuum heat treating

- Induction heating

Our equipment list

Machining equipment

CNC lathe: 250+

CNC milling machine: 40+

Universal lathe: 1

Universal milling machine: 3

Wire EDM: 1

Wire EDM: 1

Hole Drilling EDM: 1

Surface grinding machine: 3

Cylindrical grinding machine: 2

Sawing machine: 2

Inspection Equipment

Coordinate measuring machine (CMM): 1

Profile projector: 2

Image dimension measurement system-coaxial illumination: 2

Surface texture measuring instrument: 2

Contour measuring instrument: 2

Hardness tester: 1

Stereo microscope: 25

Most recent update:2024-11-21

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Development and production of prototype/Small-scale production | NC machining | NC milling NC lathe machining |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining Electric discharge machining |

| Mass production | Grinding processing | Plane grinding Internal grinding |