- Telephone number: +66-38-447-147-8

- FAX: +66-38-447-149

- Website

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Optical parts manufacturing( Parts manufacturing / Machinery part ) |

|---|---|

|

|

Progressive press (35 - 80 t)( Mass production / Metal press ) |

|

|

Connector manufacturing( Parts manufacturing / Electrical part ) |

|

|

Leaf spring die( Die manufacturing / Spring mold ) |

|

|

Thickness: below 0.2 mm( Mass production / Metal press ) |

|

|

Precision sheet metal machining( Development and production of prototype/Small-scale production / Sheet-metal processing ) |

|

|

Drawing die( Die manufacturing / Press die ) |

Icon

Company info

| Company name | NISHII FINE PRESS (THAILAND) CO., LTD. | Website URL | http://www.nishii-ss.com/ |

|---|---|---|---|

| Street address |

Phan Thong Chonburi Kingdom of Thailand

[See map] |

Person in charge | Patcharin |

| Telephone number | +66-38-447-147-8 | Fax number | +66-38-447-149 |

| Capital | 59,000,000 THB | Employees | 46 |

| Annual sales | Unregister | EMIDAS Member Number | 89784 |

| Main 3 products |

|

||

PR message

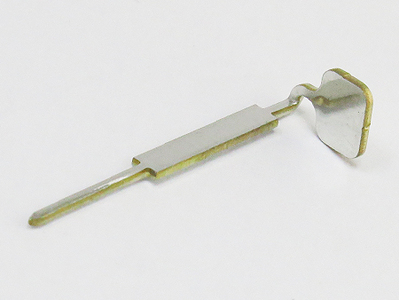

In our company, we specialize in precision pressing of small and thin components, such as automotive parts, digital camera and mobile phone components, using the latest equipment in a clean and comfortable working environment.

Moving forward, as a supply base for automotive parts and precision pressed components in Thailand, we aim to provide the highest standards in both quality and delivery time, while always being mindful of providing flexible and responsive service.

【Products Handled】

- Automotive parts [connectors, terminals, contacts, washers]

- Camera internal parts, reflectors, mobile phone components, small precision barrels, and more.

- We also handle the creation of new molds and maintenance of molds made by other companies.

【Details of Precision Pressing】

■ Materials:

We can handle any material, including iron, copper, nickel silver, phosphor bronze, stainless steel, plastic film, and mirror-finish aluminum.

■ Shapes:

We can process thin materials ranging from 0.06mm to 2mm in thickness, including punching, bending, and shallow drawing.

■ Proposing Capability:

We propose the optimal molds by thoroughly considering factors such as PM, production cuts, lifetime production quantities, and accuracy. Our multifaceted consideration also leads to cost reduction, which is highly appreciated.

■ Delivery Time:

We respond flexibly to short delivery times without compromising on quality.

If your company is considering new projects or production transfers, please do not hesitate to contact us.

Most recent update:2025-01-15

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Progressive die designing (light electrical) Progressive die designing (auto) General metal press die |

| Designing | Jig and tool designing | General jig designing Mass production jig designing |

| Designing | Electrical planning | Electrical machinery and apparatus designing |

| Development and production of prototype/Small-scale production | Machining | General-purpose milling General-purpose lathe machining Tapping Machining/Handles small-scale production (order from 1 piece) Stainless steel High rigid material Aluminum alloy Nickel alloy |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining Micro hole machining Electric discharge machining |

| Development and production of prototype/Small-scale production | Sheet-metal processing | Precision sheet metal machining Sheet metal protocol manufacturing |

| Development and production of prototype/Small-scale production | Jig manufacturing | Mass production jig manufacturing |

| Development and production of prototype/Small-scale production | Prototype processing | Punching Bending |

| Die manufacturing | Press die | Designing Manufacturing Part processing Plate machining Drawing die Bending die Blanking die Progressive die Single press die Below 60 t Compound die |

| Die manufacturing | Spring mold | Designing Manufacturing Spring die part processing Wire spring die Leaf spring die |

| Mass production | Metal press | Bending Blanking Shaving Iron Stainless steel Aluminum Copper Brass Phosphor bronze Plated steel plate Stainless steel material for spring Nickel Thickness Thickness Beryllium copper Single press (below 80 t) Progressive press (35 - 80 t) |

| Surface treatment | Coating | Air-spray coating Electrostatic coating |

| Surface treatment | Polishing/Lapping | Electropolishing Chemical polishing |

| Surface treatment | Barrel polishing | Barrel finishing (vibration) Barrel finishing (rotation) |

| Surface treatment | Other surface treatment | Buffing |

| Assembly/Inspection | Assembly | Precision equipment assembly Industrial machinery assembly |

| Parts manufacturing | Machinery part | Optical parts manufacturing |

| Parts manufacturing | Electrical part | Connector manufacturing Other electrical part manufacturing |

| Parts manufacturing | Electric board and electronic part | Electronic parts assembly and wiring |

| Parts manufacturing | Spring | Thin leaf spring Terminal spring |

| Product manufacturing | Production property | Other industrial machinery manufacturing Electrical machinery and apparatus manufacturing Energy-saving equipment/Automatic instrument manufacturing Optical products manufacturing |

| Product manufacturing | Household commodity | Office equipment manufacturing |

| Product manufacturing | Furniture/Interior | Lighting equipment manufacturing |

| Product manufacturing | Others | Telecommunication equipment manufacturing |