- Telephone number: +66-2-136-7474

- FAX: +66-2-136-7475

- Website

- Basic Info

- Equipment

- Technology & Products

- Map / HQ

Surface Modification Technologies MKS Treatment® and GMT Treatment® for Improved Resin Flow and Release Performance

Industry

---

Specifications

- Materials: ---

- Lots: ---

- Precision: ---

Conventional technologies/differences from other companies

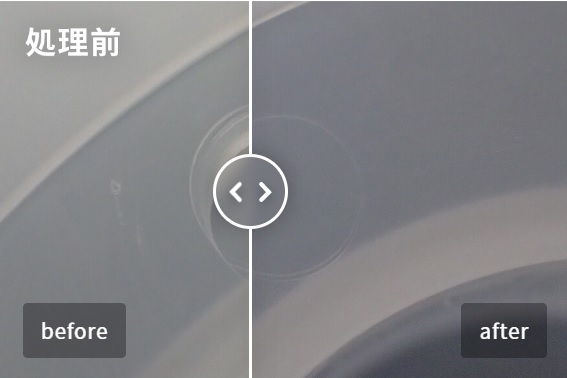

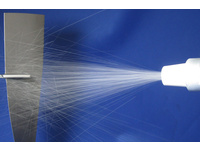

In resin (plastic) molding, issues such as sink marks, weld lines, ejector pin marks, and adhesion to molds frequently cause defects. To resolve these challenges, we developed surface modification technologies MKS Treatment® and its advanced version GMT Treatment® using air blast technology. These technologies create precise surface textures on molds, improving resin flow and release performance.

■ Features

Optimization of Resin Flow: Creates uniform surface textures ranging from nanometers to a few micrometers on mold surfaces, minimizing the contact area between the resin and the mold. This prevents premature cooling of the resin, enabling smoother flow.

Improved Release Performance: The non-directional surface structure reduces adhesion caused by resin shrinkage, ensuring smooth release after molding.

High Versatility: Enables optimal surface modification tailored to mold shapes and purposes, making it adaptable to various molding environments.

Advanced GMT Treatment®: Building on MKS Treatment®, GMT Treatment® adds further functionality, delivering exceptional results in high-precision molding environments.

■ Capabilities

Processing Precision: Surface modification precision ranges from nanometers to micrometer levels.

Applicable Targets: Molds for resin molding.

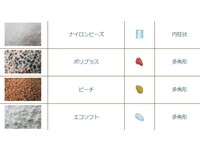

Compatible Materials: Resin, glass, ceramics, and other brittle materials.

■ Case Studies

Automotive Parts Molding: Successfully suppressed ejector pin marks and weld lines, enhancing appearance quality.

Home Appliance Components: Improved release performance, reducing molding cycle time.

Medical Device Parts: Suppressed warping caused by resin shrinkage, ensuring precision.

■ Applications

Addressing defects in resin molding.

Manufacturing high-precision molded components.

Enhancing manufacturing efficiency and quality.

MKS Treatment® and GMT Treatment® are optimal technologies for reducing costs and achieving high quality in molding processes requiring improved mold surface performance.

■ For more details, please contact us.

Company info

| Company name | Fuji Blastech (Thailand) Co.,Ltd. | EMIDAS Member Number | 90014 |

|---|---|---|---|

| Country | Kingdom of Thailand | Street address |

A.Bangplee Samut Prakan Kingdom of Thailand |

| Telephone number | +66-2-136-7474 | Fax number | +66-2-136-7475 |

| Employees | Annual sales | ||

| Employees | 6 | Person in charge | Mikihiro Hasegawa |

| Type of manufacturing | Jigs and tools / Electronic parts / Transportation equipment | ||