- Telephone number: +66-2-136-7474

- FAX: +66-2-136-7475

- Website

- Basic Info

- Equipment

- Technology & Products

- Map / HQ

Surface Modification Technology with Shot Peening and WPC Treatment

Industry

---

Specifications

- Materials: ---

- Lots: ---

- Precision: ---

Conventional technologies/differences from other companies

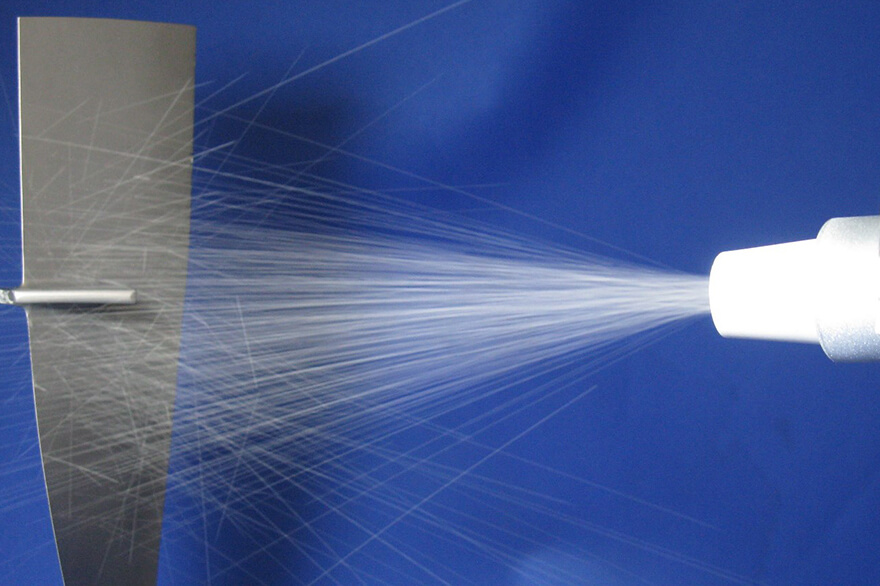

Shot peening is a surface modification technology where spherical abrasive particles (shots) are projected onto metal surfaces at high speed, introducing compressive residual stress to improve fatigue strength and wear resistance. Its simplicity and cost-effectiveness have made it widely used in the automotive, aerospace, and tool industries, among others.

We have developed enhanced shot peening techniques, including micro-particle peening technology “WPC Treatment®” and “α Treatment®.” These technologies build upon the advantages of conventional shot peening to provide even greater improvements in wear resistance, sliding performance, friction reduction, prevention of lubricant failure, and surface nanocrystallization for higher functionality in surface modification.

■ Features

Significant Improvement in Wear Resistance and Fatigue Strength: Introduces compressive residual stress to reduce damage and wear.

Surface Roughness Suppression: Smooth finishes enhance sliding performance.

Reduced Friction Resistance: Improves component efficiency and reduces energy consumption.

Prevention of Lubricant Failure: Extends lifespan and enhances reliability.

Dimensional Stability: Minimal impact on part shapes and dimensions after treatment.

■ Capabilities

Compressive Residual Stress: Achieves high stress distribution up to a depth of 0.1 mm on the surface.

Refinement: Surface layer crystal grains are refined to the nanometer level, enhancing strength.

Processable Targets: Suitable for automotive parts (crankshafts, gears), aircraft components, tools, and medical devices.

Material Compatibility: Applicable to metals (steel, titanium alloys, aluminum alloys) and high-strength materials.

■ Applications

Automotive Industry: Engine parts, transmission gears, suspension components.

Aerospace Industry: Structural components, turbine blades.

Tool Industry: Cutting tools, die performance enhancement and lifespan extension.

Medical Field: Improving the durability and sliding performance of surgical instruments.

The micro-particle peening technologies “WPC Treatment” and “α Treatment” deliver surface modification effects that surpass conventional methods, contributing to enhanced component performance. These solutions improve reliability and reduce costs in various industrial sectors.

■ For more details, please contact us.

Company info

| Company name | Fuji Blastech (Thailand) Co.,Ltd. | EMIDAS Member Number | 90014 |

|---|---|---|---|

| Country | Kingdom of Thailand | Street address |

A.Bangplee Samut Prakan Kingdom of Thailand |

| Telephone number | +66-2-136-7474 | Fax number | +66-2-136-7475 |

| Employees | Annual sales | ||

| Employees | 6 | Person in charge | Mikihiro Hasegawa |

| Type of manufacturing | Jigs and tools / Electronic parts / Transportation equipment | ||