- Telephone number: +81-52-793-3080

- FAX: +81-52-793-1079

- Website

- Basic Info

- Equipment

- Technology & Products

- Movie

- History, Philosophy & Quality

- EMIDASBLOG

- Map / HQ

About "current density" - Explanation from an electrical expert

Industry

Heavy electric machinery

Specifications

- Materials:Copper

- Lots:1 - 100 lots

- Precision:Within general tolerance

Conventional technologies/differences from other companies

The difference between current and current density.

[Material]

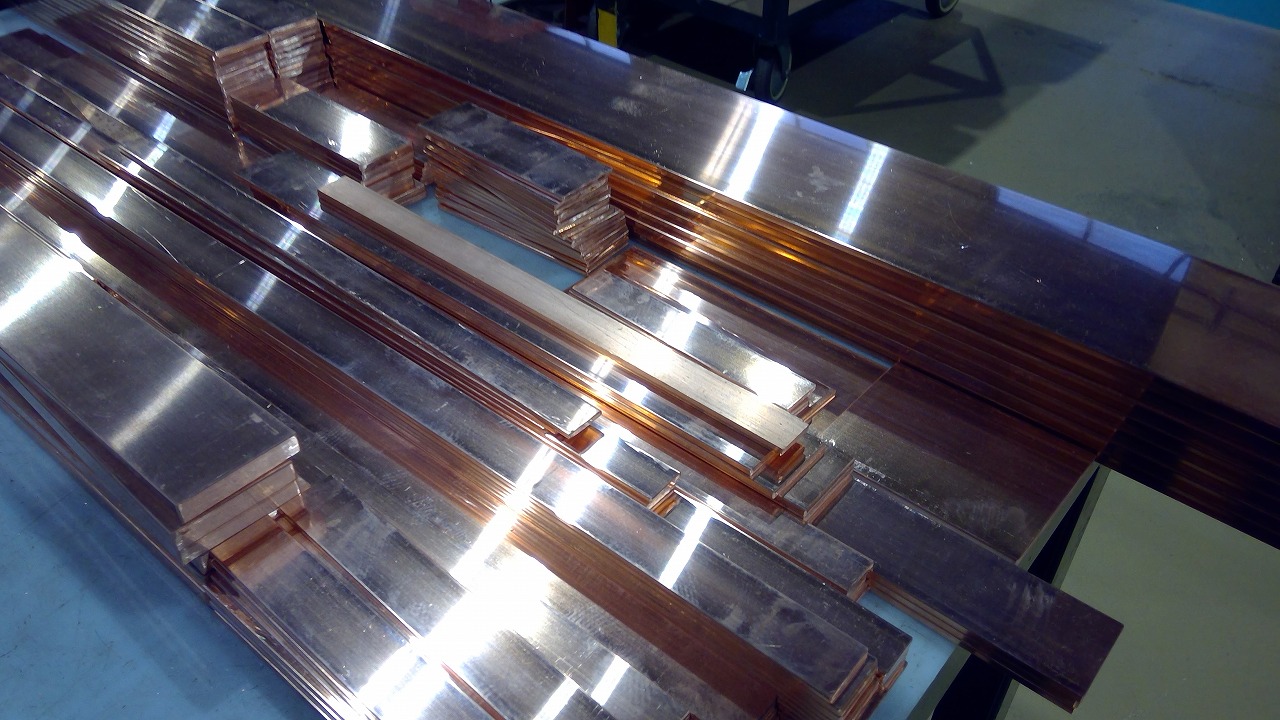

Copper busbar/copper rod processing

We handle purchase → processing → plating

[Dimensional tolerance]

Within the general tolerance range

Please contact us about processing tolerances.

[Lot]

1-100 pieces (we accept orders from 1 piece)

[Industry/Use]

Heavy electrical industry, processing of electrical parts related to panels

[Material dimensions]

We are good at copper busbars 3mm-20mm!

We process φ10-φ55 on lathes almost every day

[Processing machines/processing methods]

Press processing, machining, lathe processing

[Features]

Current = amount of charge (electricity) moving over time

Power density = current divided by electrode area. Refers to the current value per unit area.

In other words, just using a huge amount of copper because it is a large power facility, reducing it to save money, using larger components inside the panel, or using a small, compact design is insufficient.

To deliver electricity safely and reliably, a copper busbar of the proper thickness and dimension is required.

So, how can designers determine and record it on a drawing?

First, determine the current density. The unit is A/cm2.

Current density is determined by dividing the current value (A amperes) by the cross-sectional area of the electrode.

If the current is 10A and the area is 5cm2, then 10A ÷ 5 = 2A/cm2.

This indicates a current of 2A travels across an area of 5 cm2. To pass a current of 2A via a 3cm2 cross-sectional area, a current of 2×3=6A will flow through the copper busbar, as the A (amperes) limit is regulated for facilities and residences that receive electricity.

Naturally, the greater the current value, the higher the needed value, and a mistake might result in a catastrophic disaster, so we assume it must be quite tough for the folks drafting the designs at each organization.

Only owing to the work of individuals behind the scenes can we safely take power for granted.

Ishigaki Shoten works with such people to acquire, process, surface treat, and deliver copper busbars.

If you have any issues with copper busbar processing, please contact us.

We have been working hard on copper processing for 75 years anf we are very fond of our authenticity.

Please have a look at our website for more details on copper busbar and rod processing procedures, as well as copper precision parts.

Website: http://ishigaki-st.com.

ISHIGAKI SHOUTEN Inc.

Address: 1-629 Seko, Moriyama, Nagoya City, Aichi Prefecture, 463-0068, Japan

Phone: +81-52-793-3080

Fax: +81-52-793-1079

E-mail: info@ishigaki-st.com

Contact: Sales Department, Murakami/Sodeoka

Company info

| Company name | ISHIGAKI SHOUTEN Inc. | EMIDAS Member Number | 91883 |

|---|---|---|---|

| Country | Japan | Street address |

Nagoya City Aichi Japan |

| Telephone number | +81-52-793-3080 | Fax number | +81-52-793-1079 |

| Employees | 10,000,000 JPY | Annual sales | 500,000,000 JPY |

| Employees | 25 | Person in charge | Masahiro Ishigaki |

| Type of manufacturing | Heavy electric machinery / Industrial machinery / Transportation equipment | ||