- Telephone number: +81-263-54-1003

- FAX: +81-263-54-1006

- Website

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

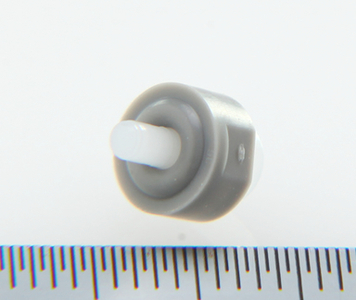

Injection molding ( Mass production / Plastic ) |

|---|---|

|

|

Injection molding die( Designing / Mold designing ) |

|

|

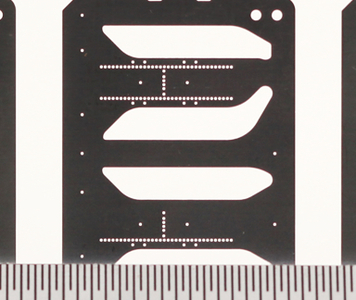

Progressive press (35 - 80 t)( Mass production / Metal press ) |

|

|

Progressive die( Die manufacturing / Press die ) |

|

|

5-face/5-axis machining( Development and production of prototype/Small-scale production / NC machining ) |

|

|

CFRP (carbon fiber reinforced plastic)( Mass production / Plastic ) |

|

|

Part processing( Die manufacturing / Plastic mold ) |

|

|

Engineering plastic( Mass production / Plastic ) |

|

|

Elastomer( Mass production / Plastic ) |

|

|

Dual molding( Mass production / Plastic ) |

Icon

Company info

| Company name | Shinshu Yoshino Electric Co., Ltd. | Website URL | http://www.syd-tech.jp/ |

|---|---|---|---|

| Street address |

Shiojiri City Nagano Japan

[See map] |

Person in charge | Nihira |

| Telephone number | +81-263-54-1003 | Fax number | +81-263-54-1006 |

| Capital | 50,000,000 JPY | Employees | 78 |

| Annual sales | Unregister | EMIDAS Member Number | 92117 |

| Type of manufacturing | Jigs and tools / Office automation equipment / Electrical component for transportation equipment | ||

| Main 3 products |

|

||

| Primary clients |

|

||

PR message

Shinshu Yoshino Electric is working towards the relatization of "manufacturing that only produces high-quality products" by bringing together the power of all our staff members. The key to achieving this lies in the directional capabilities that each individual demonstrates.

"Direction" refers to supervising the production site, driving projects forward, defining the right course of action, and bringing it to fruition. We do not see manufacturing as simply producing what our customers request. Instead, we take the time to understand what kind of products our customers truly need and provide technical proposals to realize them through the most optimal manufacturing processes.

Furthermore, we implement strict quality control standards across all departments to enhance quality, reduce costs, and shorten delivery times. We are committed to consistently delivering high-quality products and services.

"Quality," "Cost," and "Delivery"—we apply our directional capabilities to excel in all these aspects. This is the standard of manufacturing at Shinshu Yoshino Electric.

Most recent update:2026-03-03

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Injection molding die Progressive die designing (light electrical) Progressive die designing (auto) General metal press die |

| Designing | Jig and tool designing | General jig designing Mass production jig designing |

| Designing | Industrial equipment designing | Automatic machinery manufacturing Energy-saving machinery designing |

| Development and production of prototype/Small-scale production | Machining | General-purpose milling General-purpose lathe machining Tapping Iron Stainless steel High rigid material Aluminum alloy Copper alloy Nickel alloy Keyway milling Simultaneous 5-axis machining Handles microfabrication Brass |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) 5-face/5-axis machining |

| Development and production of prototype/Small-scale production | Grinding processing | Plane grinding Profile grinding |

| Development and production of prototype/Small-scale production | Welding/Adhesive bonding | Plastic bonding Ultrasonic welding |

| Development and production of prototype/Small-scale production | Prototype processing | Plastic protocol machining Prototype/Small-lot molding Small-lot/Injection molding Simplified/Molding prototype mold |

| Die manufacturing | Press die | Designing Manufacturing Part processing Bending die Blanking die Progressive die Single press die Below 60 t |

| Die manufacturing | Plastic mold | Designing Manufacturing Part processing Injection molding die Insert molding die Outsert molding die Below 60 t 60 - 300 t Electrode manufacturing Cassette-type molding die Metal injection molding die Thin wall injection molding die Injection molding die for microfabrication (5 mm or smaller) Core and cavity machining |

| Die manufacturing | Powder metallurgy mold | Manufacturing |

| Mass production | Metal press | Bending Blanking Iron Stainless steel Aluminum Copper Brass Phosphor bronze Plated steel plate Nickel Thickness Thickness Single press (below 80 t) Progressive press (35 - 80 t) |

| Mass production | Mechanical processing | Five-face/axes machining Micro-hole machining Iron Stainless Cemented carbide Aluminum alloy Copper alloy Fine particle material accepted |

| Mass production | Plastic | Insert molding Outsert molding General-purpose material PMMA (polymethyl methacrylate) Engineering plastic PBT (polybutylene terephthalate) PPS (polyphenylene sulfide) LCP (liquid crystal polymer) FRP (fiber reinforced plastic) GFRP (glass fiber reinforced plastic) Elastomer Below 60 t 60 - 300 t Injection molding Thin wall molding Dual molding Biodegradable plastic CFRP (carbon fiber reinforced plastic) |

| Mass production | Welding / welding | Plastic adhesive Ultrasonic welding Hot plate welding Vibration welding |

| Surface treatment | Cleaning | Hydrocarbon cleaning |

| Surface treatment | Barrel polishing | Barrel finishing (rotation) |

| Surface treatment | Other surface treatment | Shot blast |

| Assembly/Inspection | Assembly | Industrial machinery assembly |

| Assembly/Inspection | Inspection | Metal press Plastic Measuring |

| Parts manufacturing | Machinery part | Gear manufacturing Optical parts manufacturing Mechanical parts |

| Parts manufacturing | Electrical part | Connector manufacturing Other electrical part manufacturing |

| Product manufacturing | Household commodity | Office equipment manufacturing |

| Product manufacturing | Others | Transportation equipment manufacturing Telecommunication equipment manufacturing |