- Telephone number: +66-2-182-5273

- FAX: +66-2-182-5275

- Website

- Basic Info

- Equipment

- Technology & Products

- Map / HQ

Rotary, Centrifugal, and Vibratory Barrel Polishing

Industry

---

Specifications

- Materials: ---

- Lots: ---

- Precision: ---

Conventional technologies/differences from other companies

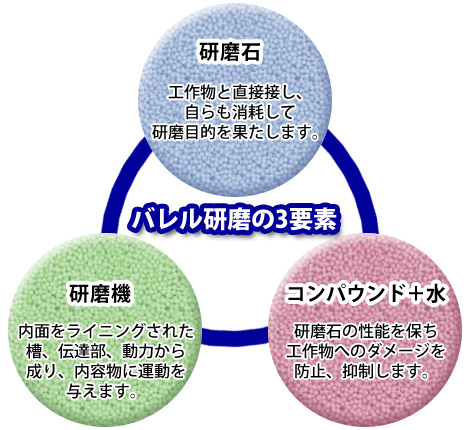

Barrel polishing is a widely used surface treatment technology in various manufacturing industries, including machined parts, pressed parts, sintered parts, and die-cast components. Our company employs three types of polishing methods: rotary barrel, centrifugal barrel, and vibratory barrel, ensuring the best treatment based on product shape and required quality. Barrel polishing is essential for final finishing in the manufacturing process, offering cost efficiency, mass processing capability, and uniform finishing.

■ Features

Low-cost, high-volume processing: Processes multiple products at once, improving production efficiency.

Suitable for complex shapes: Achieves uniform finishing on parts that are difficult to process manually.

Consistent quality: A stable polishing process ensures uniform surface treatment with minimal variations.

Optimal polishing method selection: The best polishing method is chosen based on product characteristics and desired finish.

■ Services

1. Rotary Barrel Polishing

Provides uniform polishing with low-speed rotation

Minimizes damage to products, ensuring a stable finish

Suitable for both small and large production volumes

2. Centrifugal Barrel Polishing

Offers powerful polishing for fast processing

10 to 15 times stronger polishing force than rotary barrel polishing

Ideal for products requiring high precision

3. Vibratory Barrel Polishing

Uses three-dimensional vibrations, making it highly efficient for mass production

Generates strong friction instantly, achieving a unique finish

Offers distinctive characteristics compared to other barrel methods, enabling flexible applications

■ Applications

Finishing of machined parts, pressed parts, and die-cast components

Deburring and edge finishing of precision components

Surface smoothing and gloss finishing of metal parts

Removal of rust and oxide layers

Surface treatment for plastic-molded components

We select the most suitable barrel polishing method based on product characteristics and intended use, ensuring uniform and high-quality finishing. Our barrel polishing services in Samut Prakan, Thailand, help reduce costs and improve efficiency.

■ Please contact us for more details.

Company info

| Company name | NAGANO HIDAKA (Thailand) Co., Ltd. | EMIDAS Member Number | 92627 |

|---|---|---|---|

| Country | Kingdom of Thailand | Street address |

Amphur Bang Sao Thong Samut Prakan Kingdom of Thailand |

| Telephone number | +66-2-182-5273 | Fax number | +66-2-182-5275 |

| Employees | 2,000,000 THB | Annual sales | |

| Employees | 8 | Person in charge | Kitazawa |

| Primary clients |

|

||